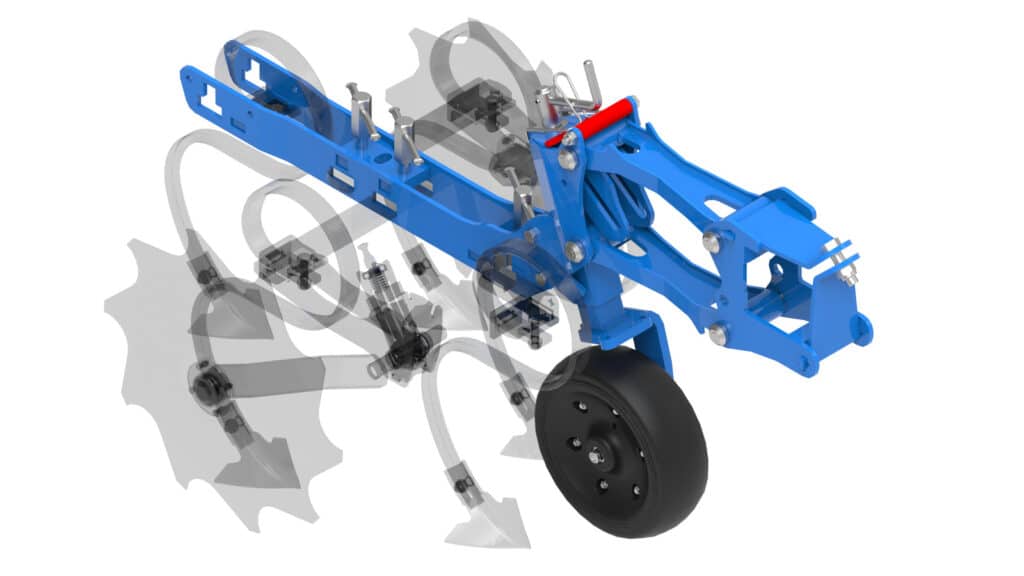

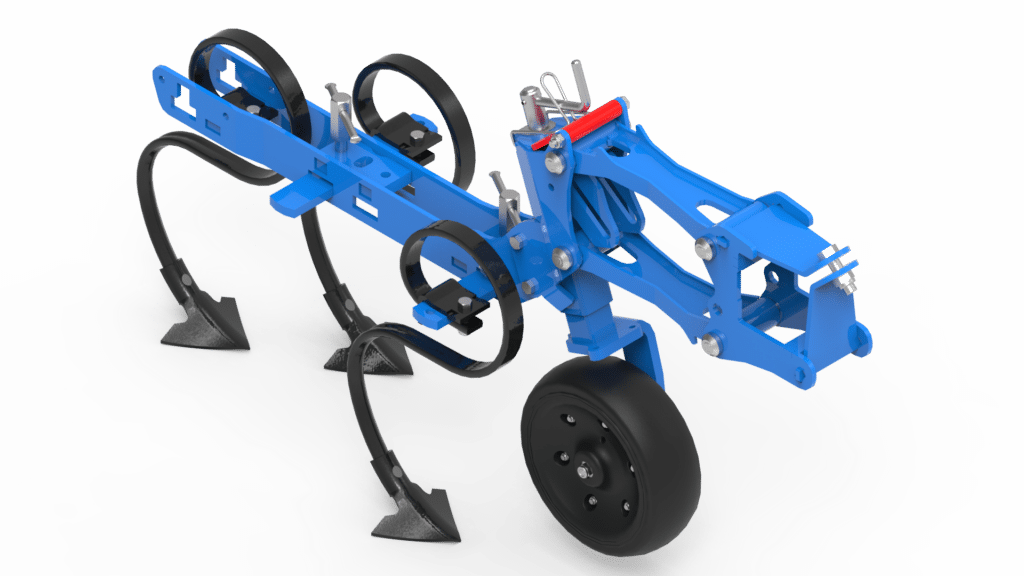

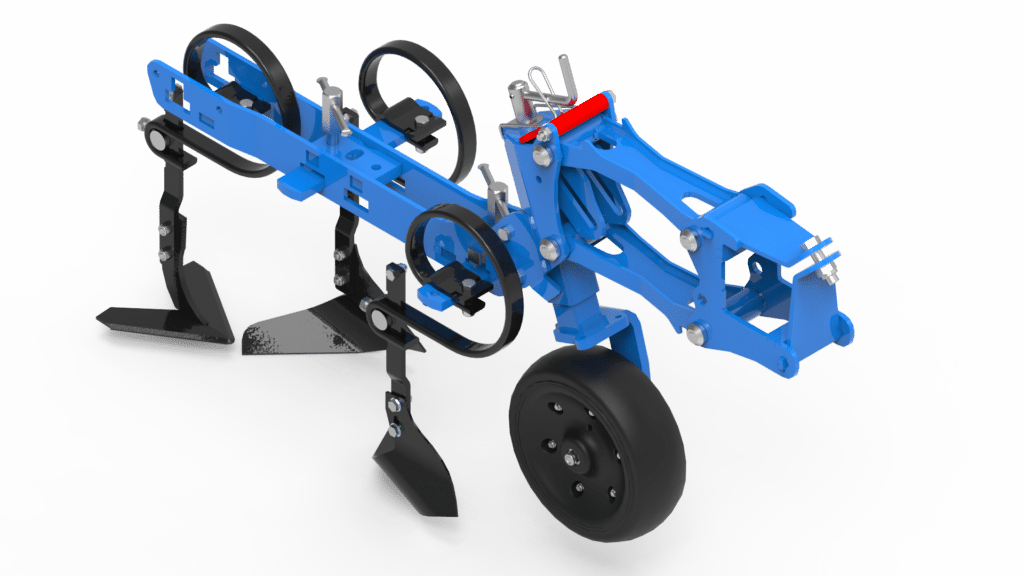

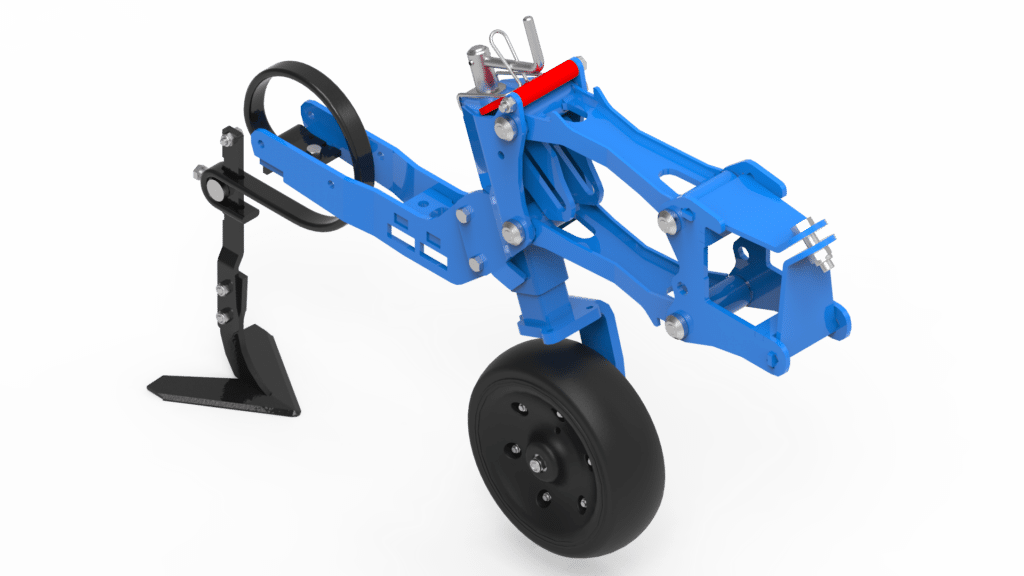

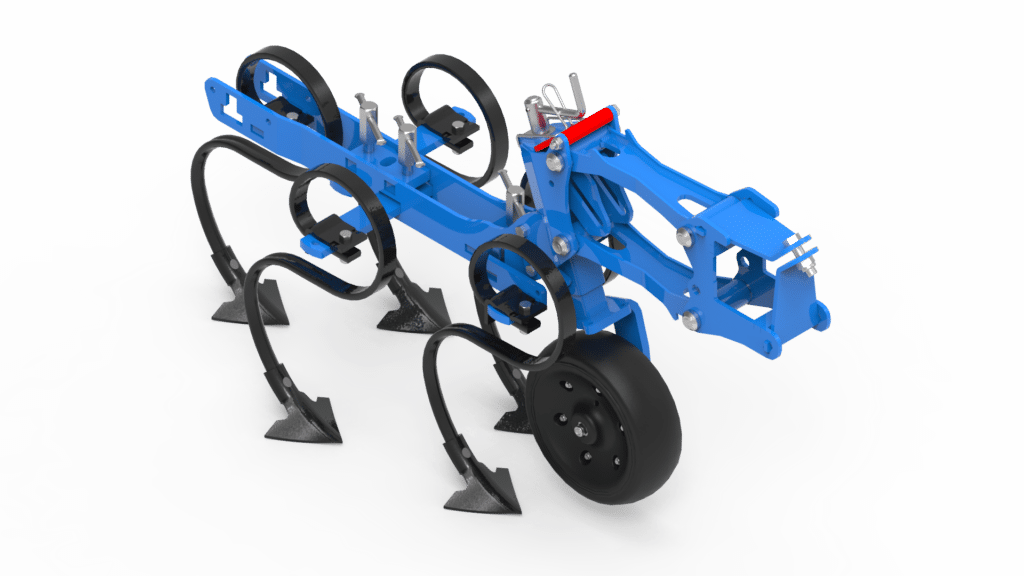

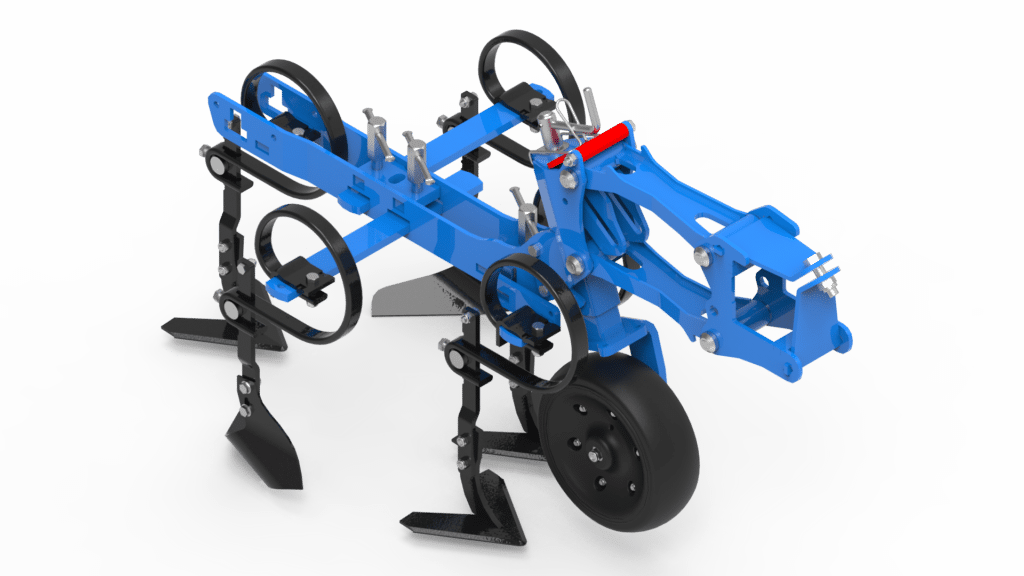

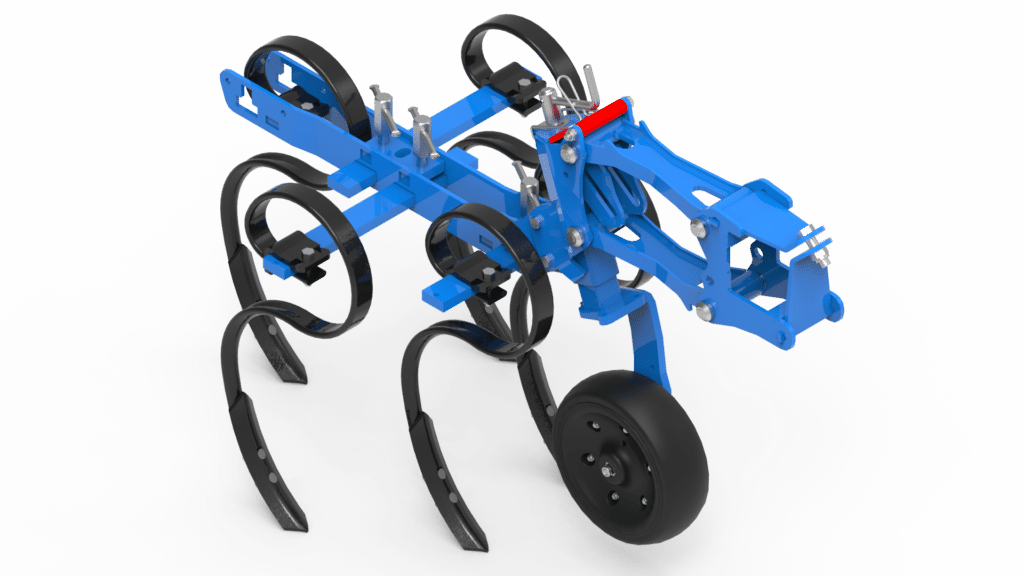

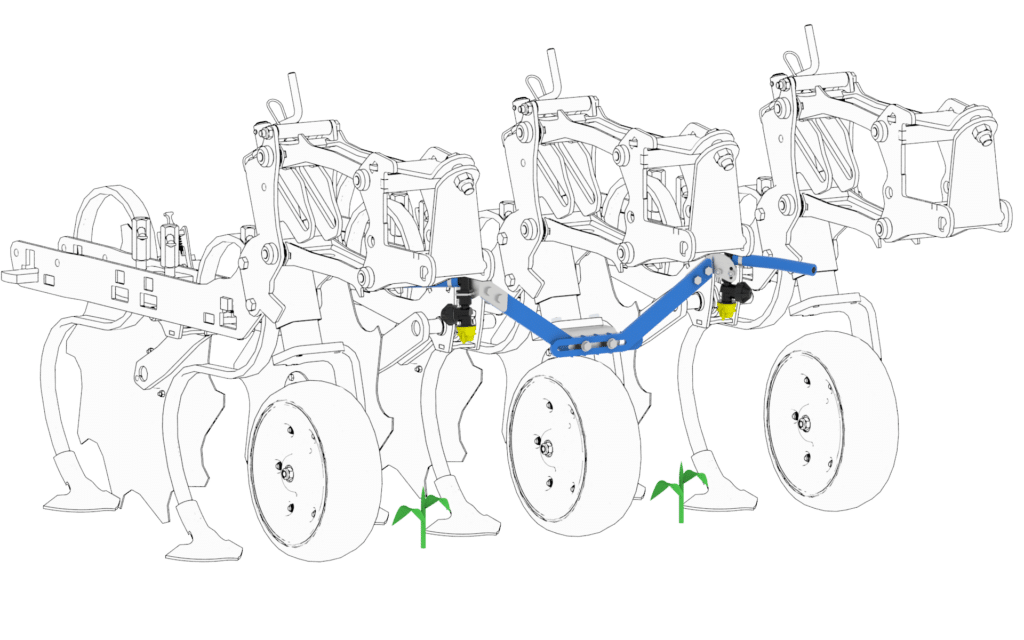

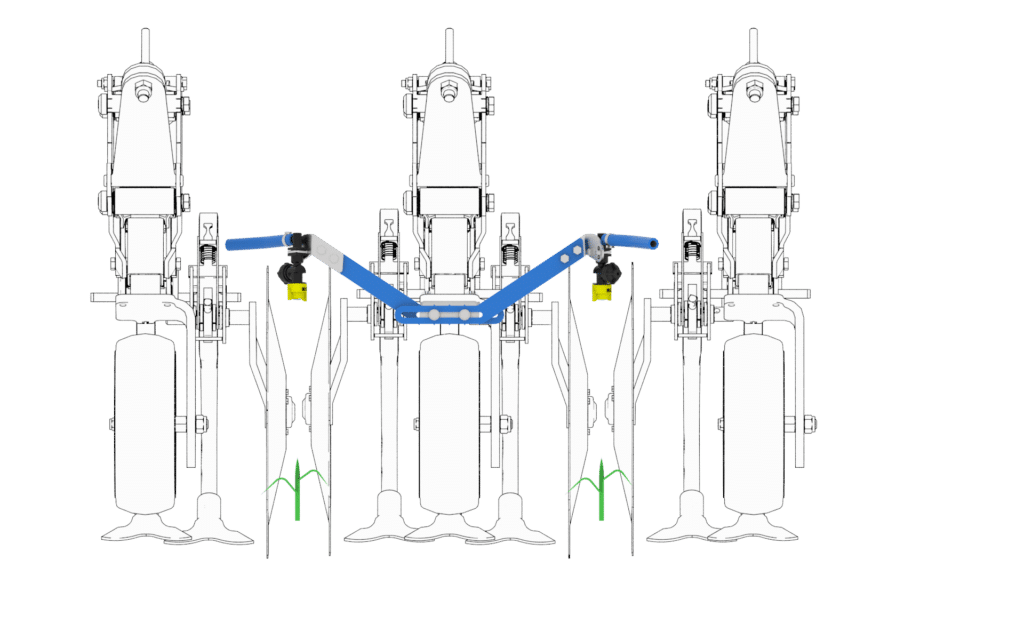

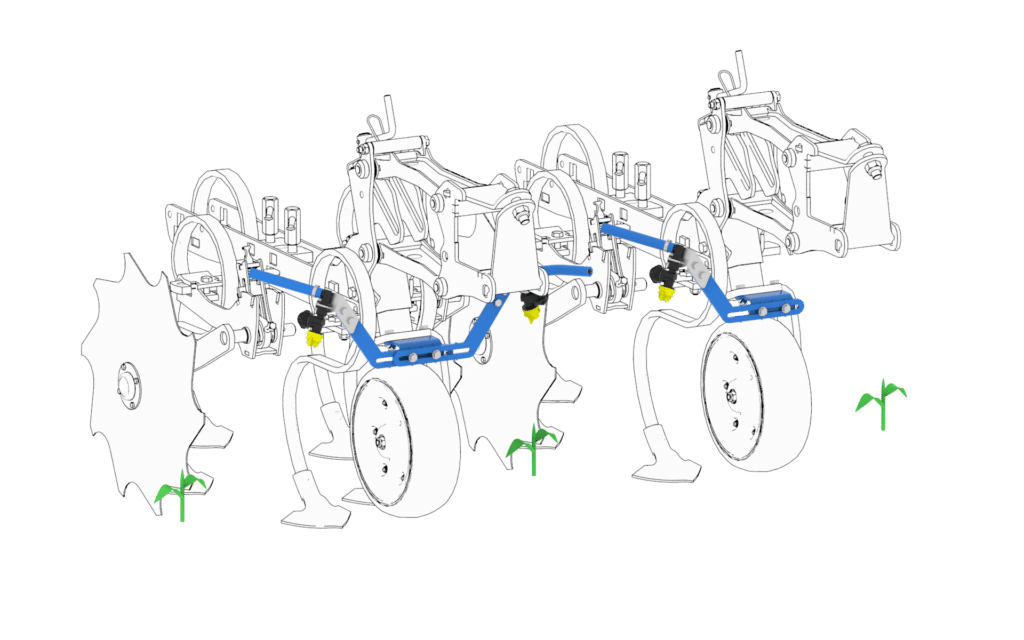

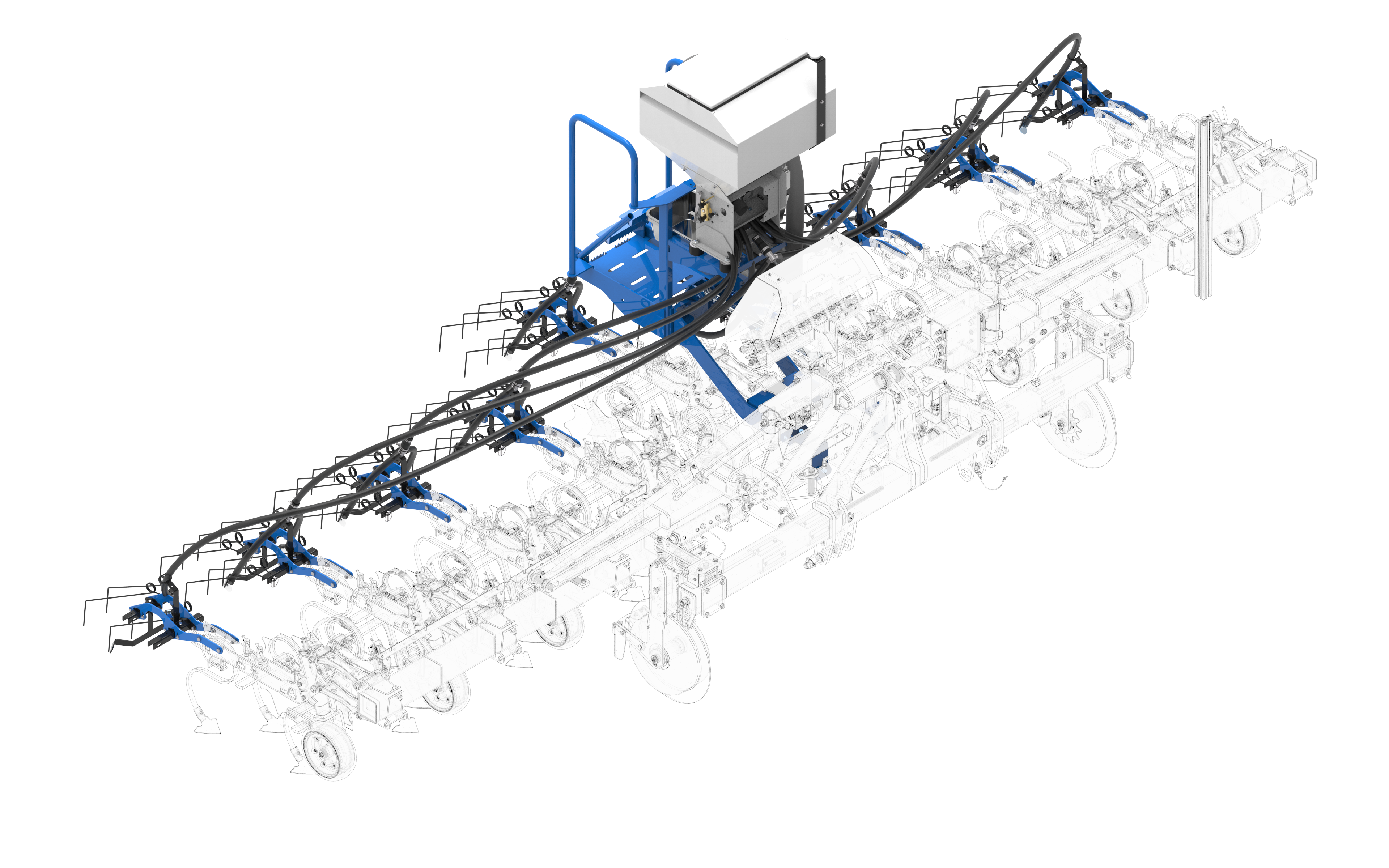

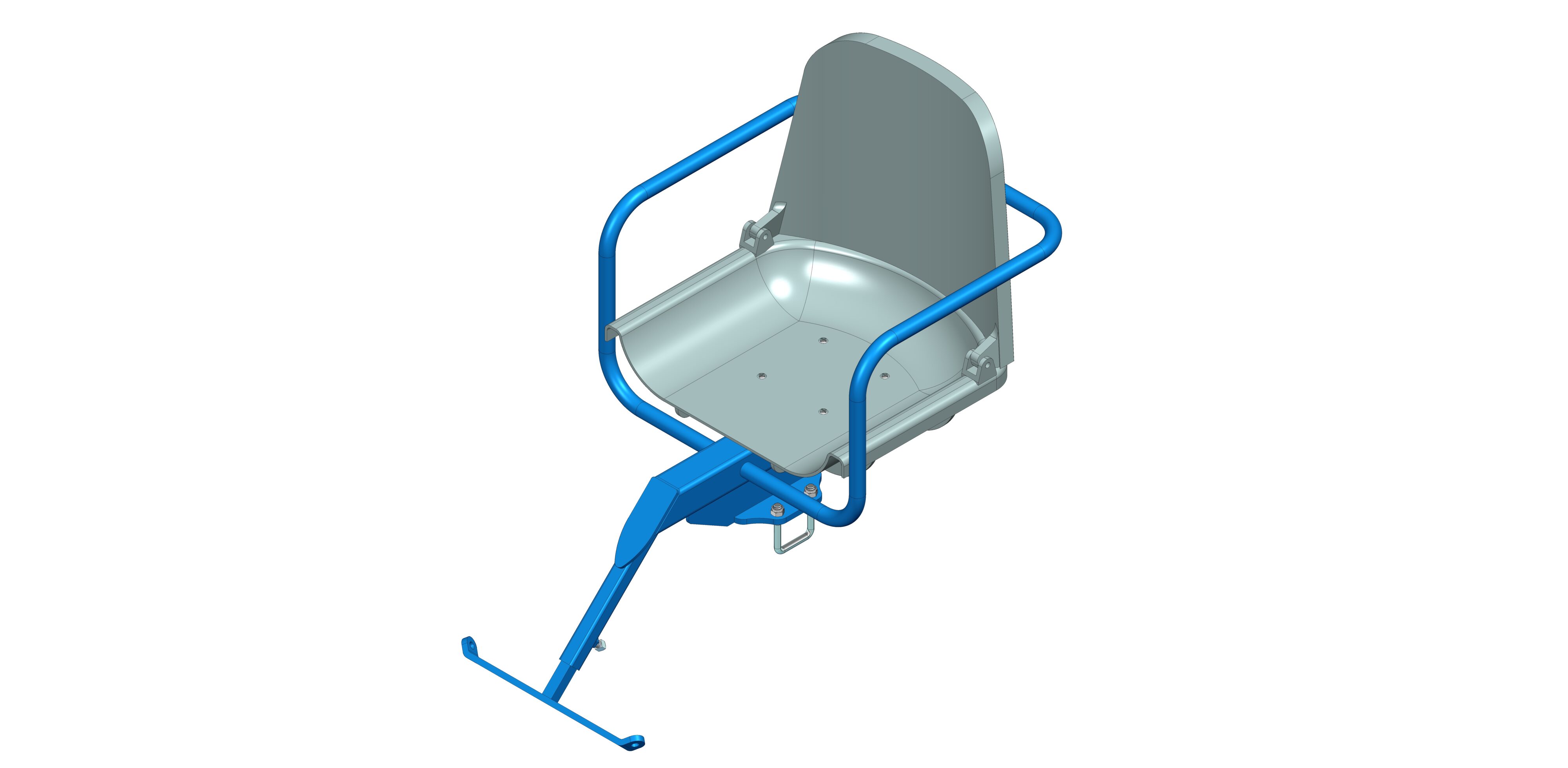

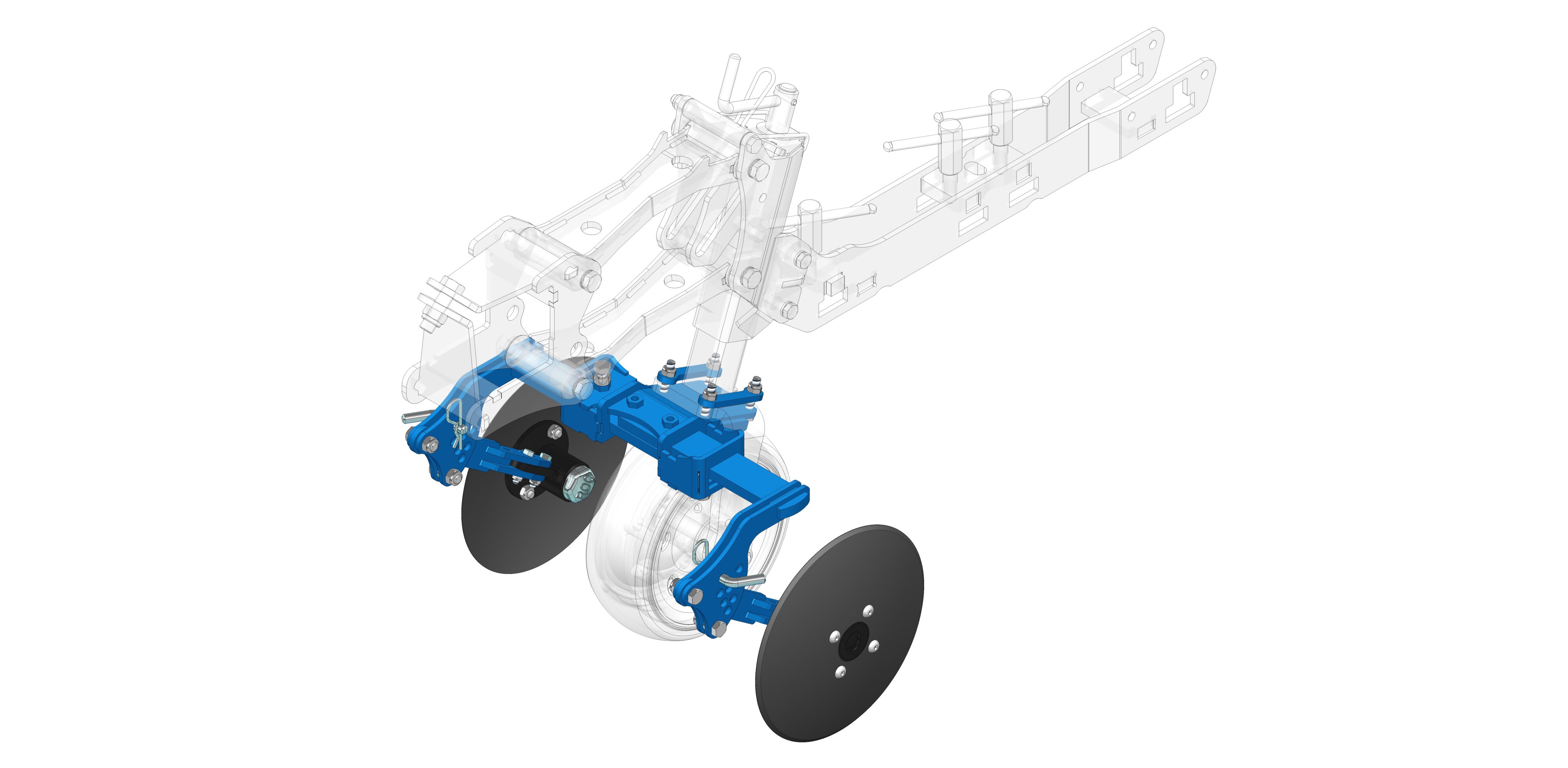

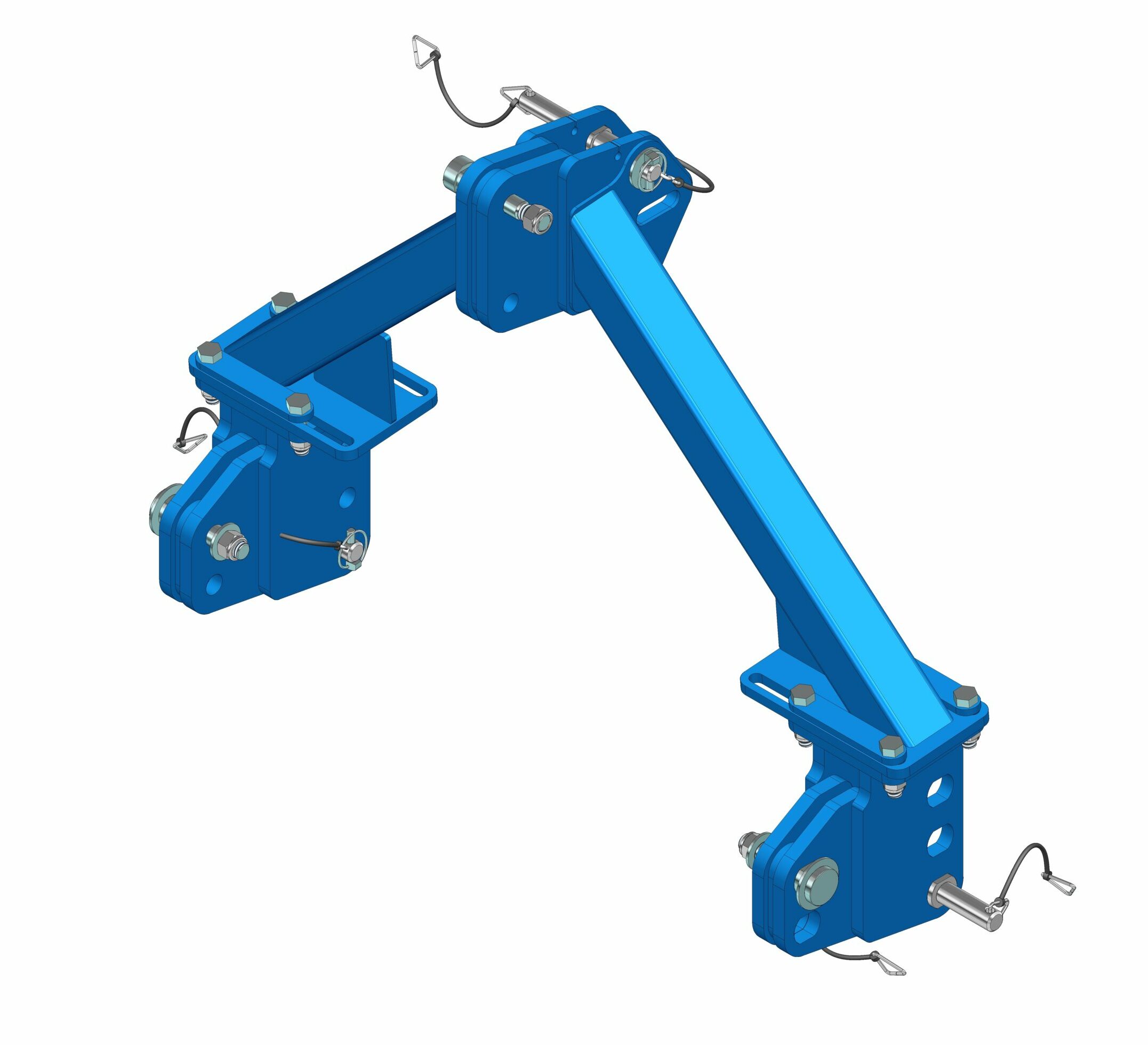

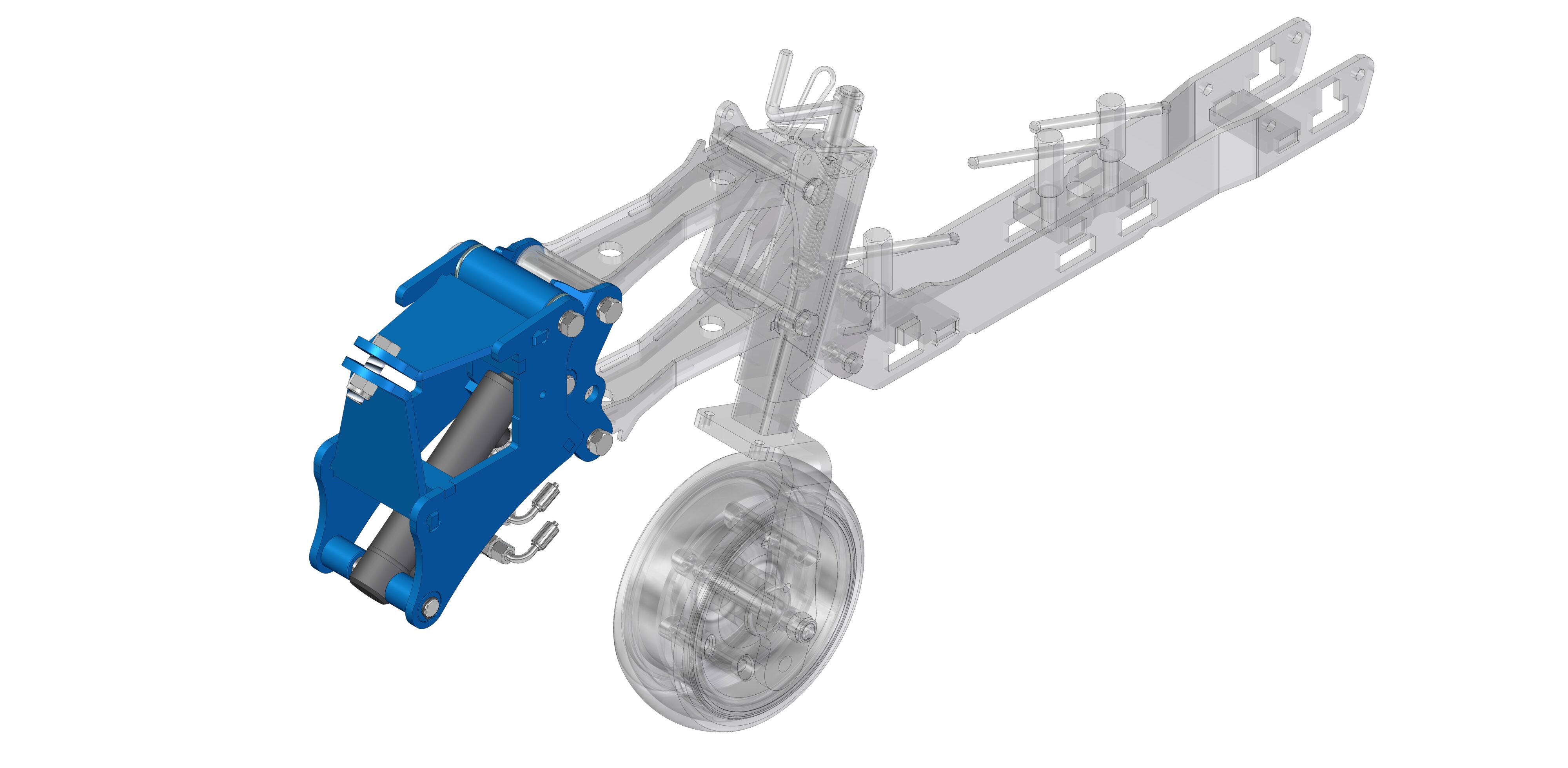

Machines ideal for clients demanding in terms of guiding and seeking work comfort and precision.

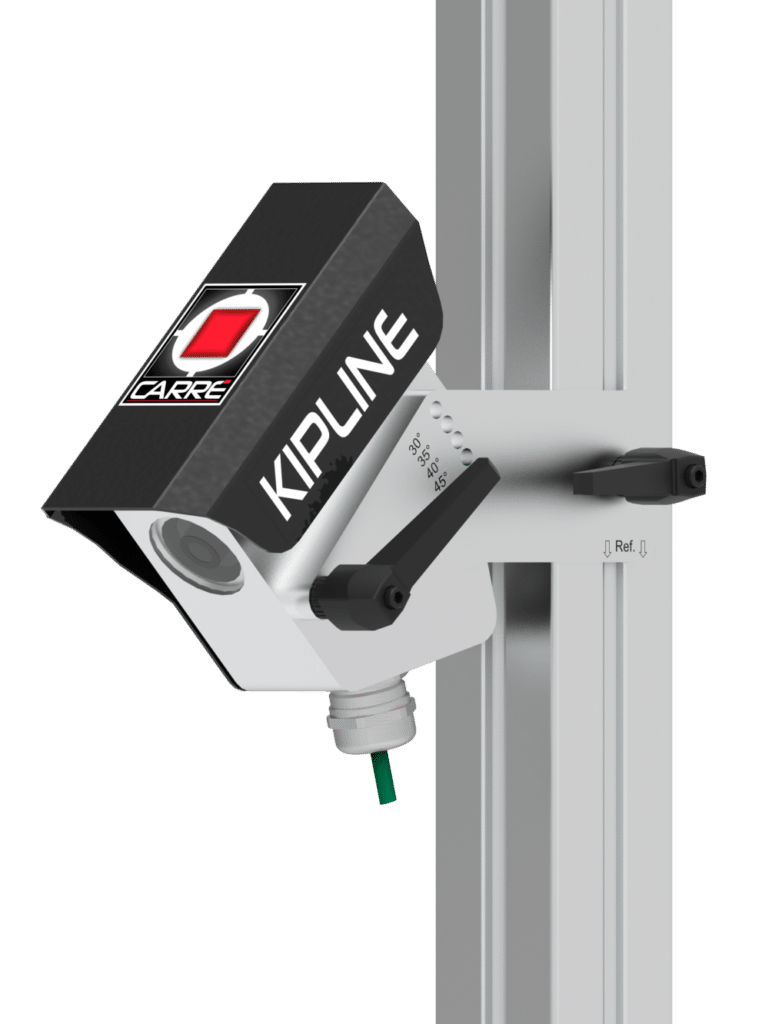

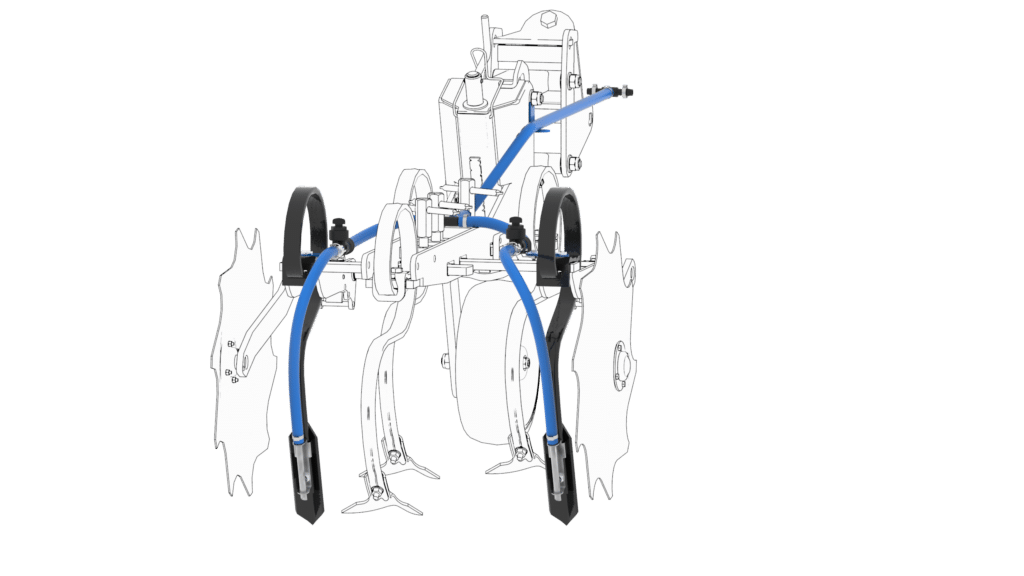

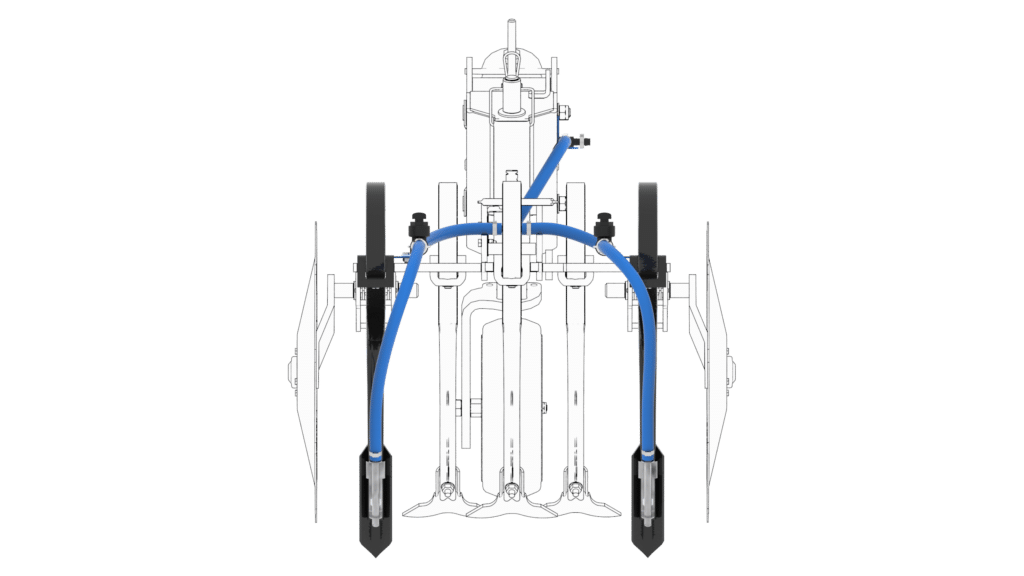

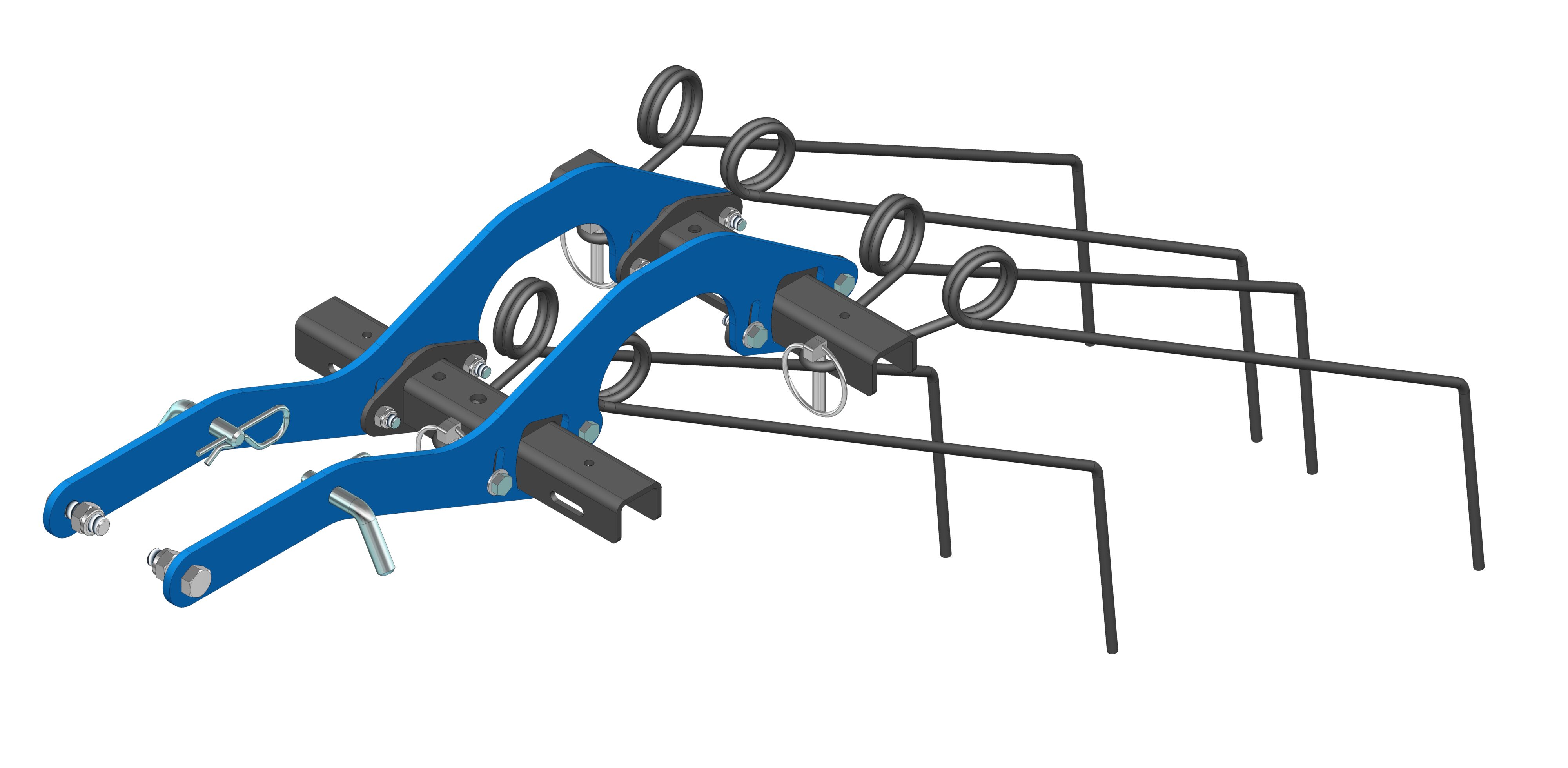

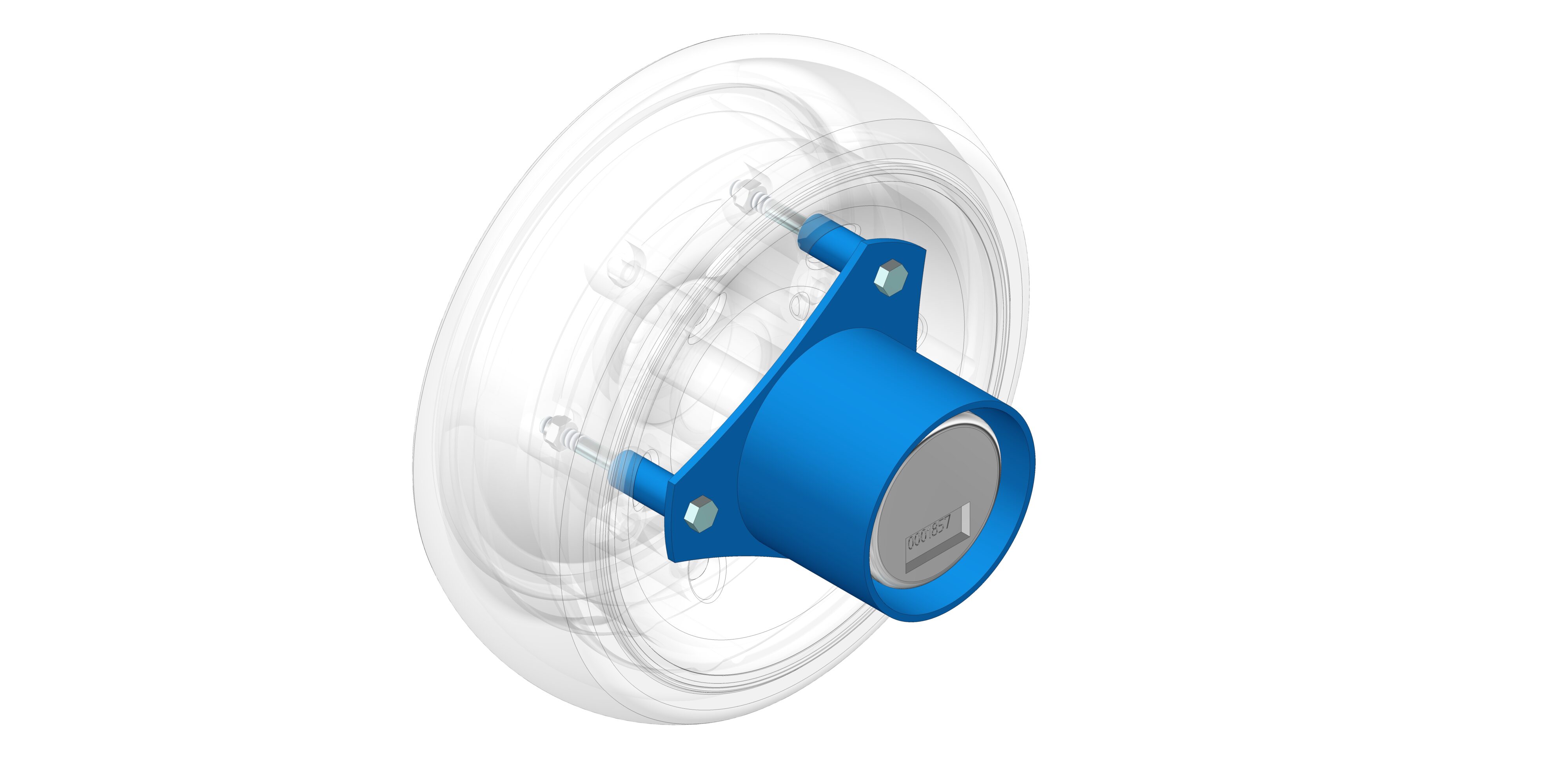

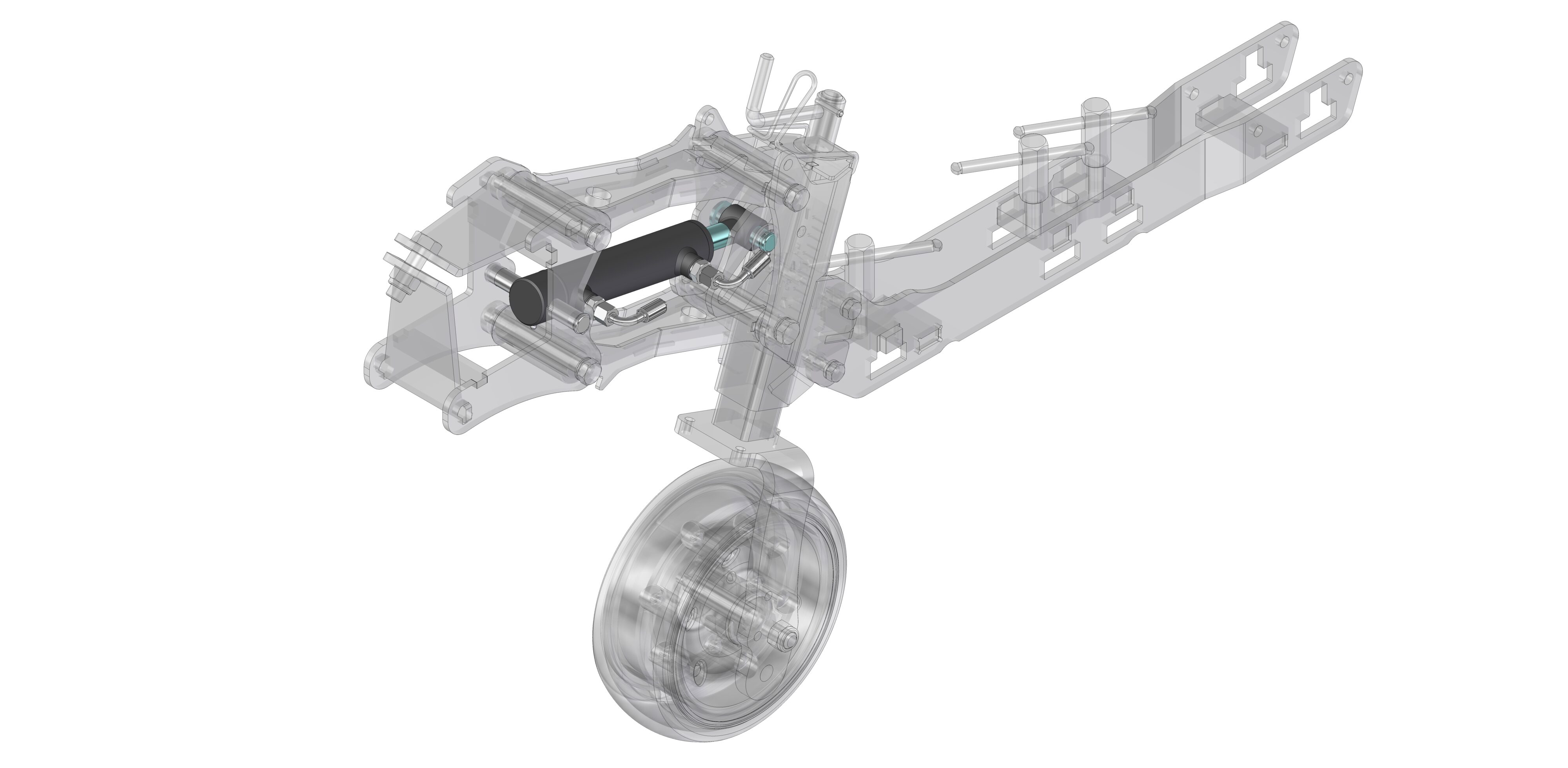

Our guiding systems developed for more than 15 years have proven their reliability.

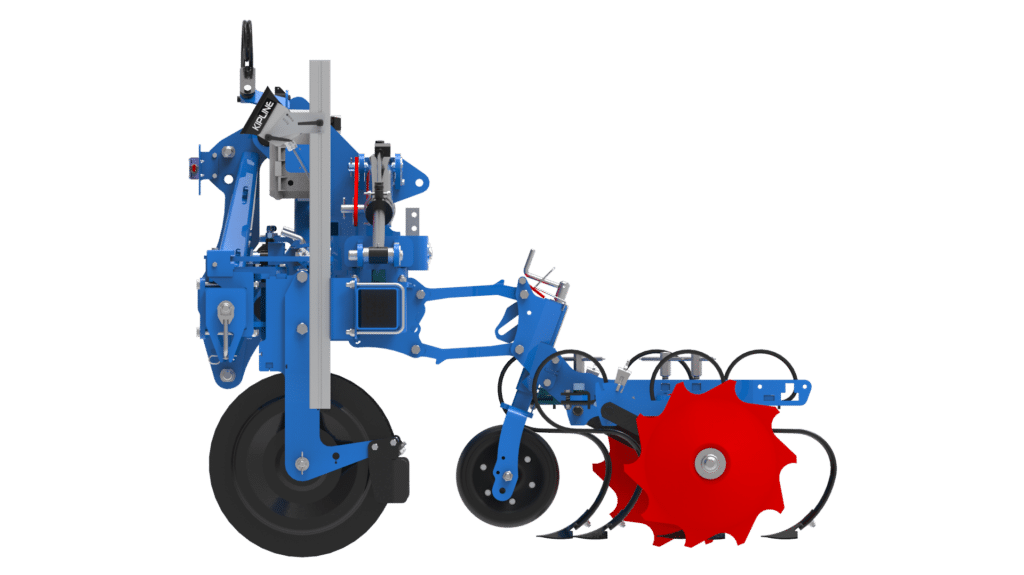

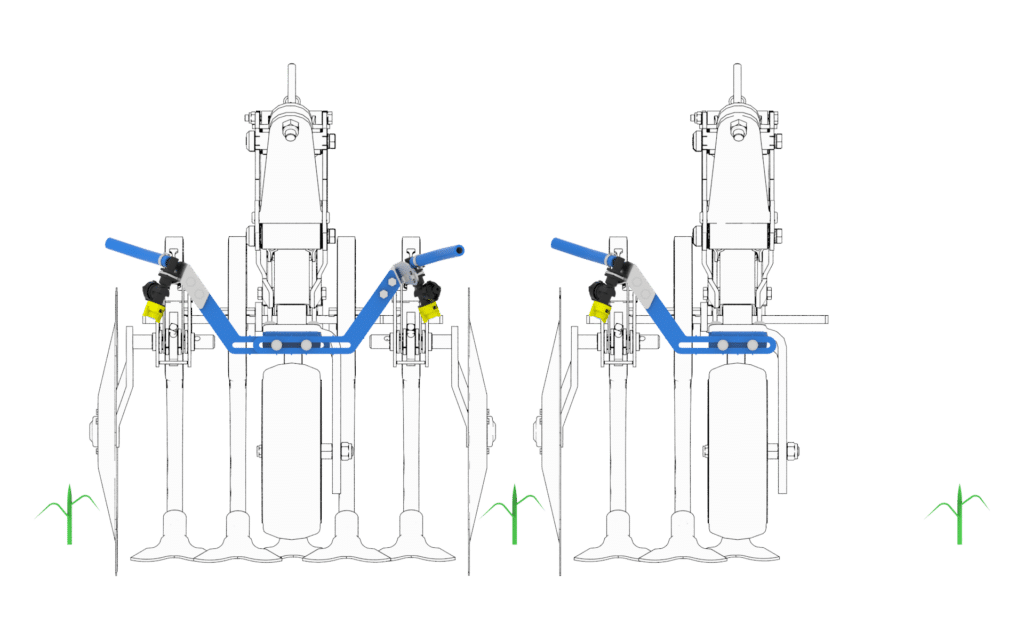

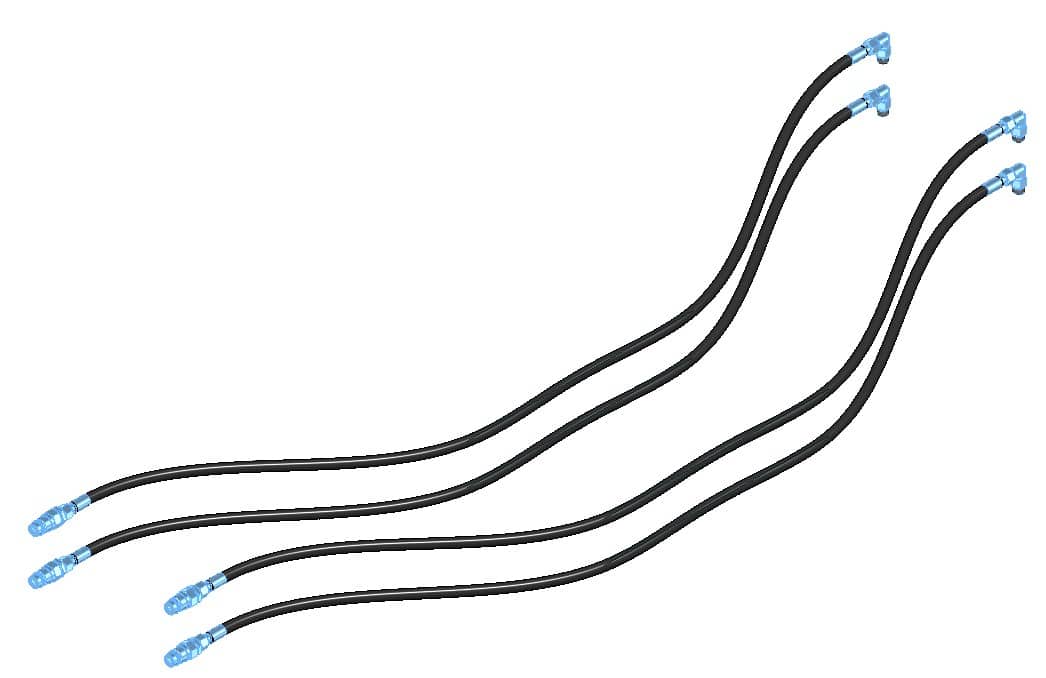

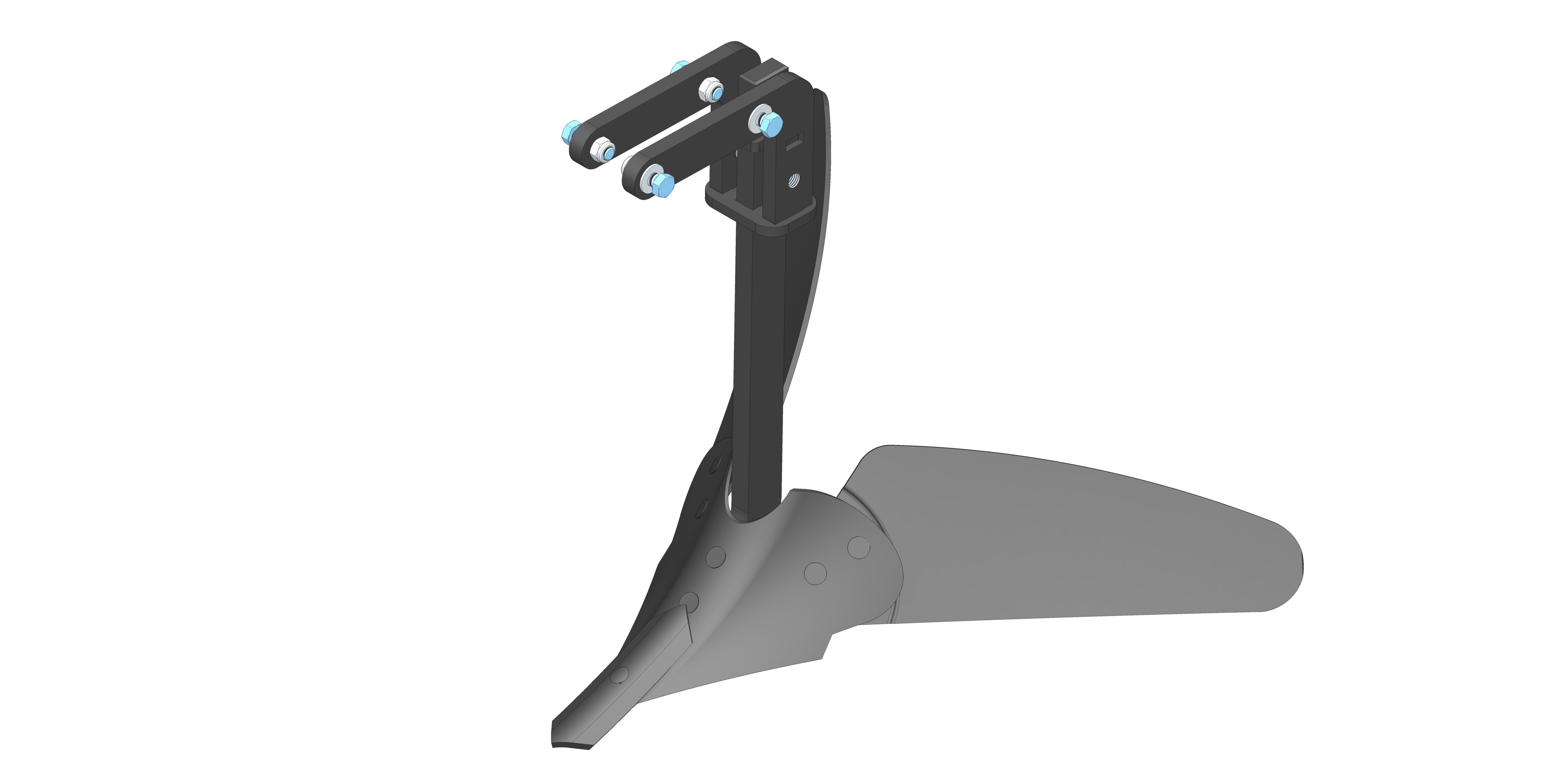

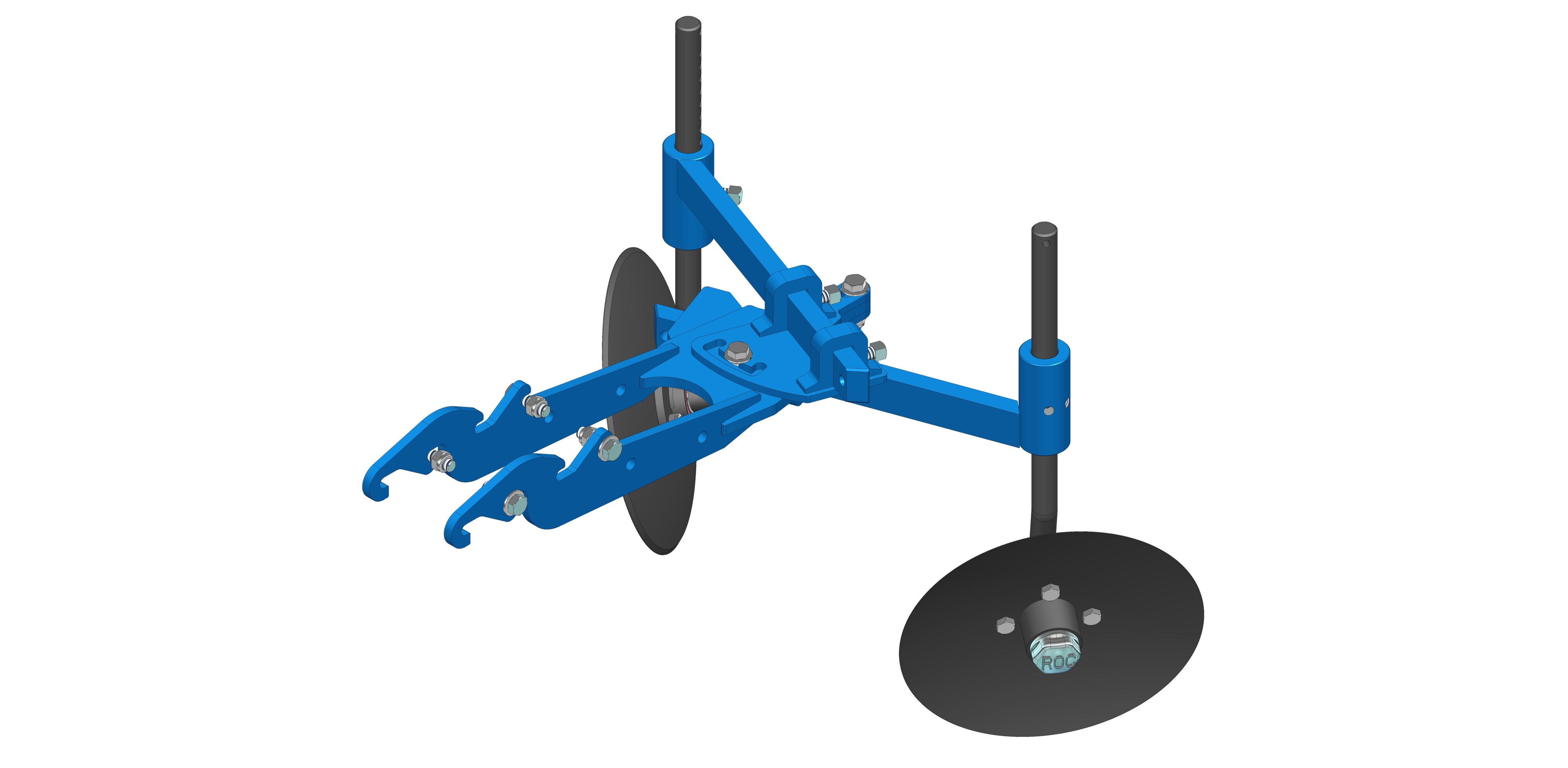

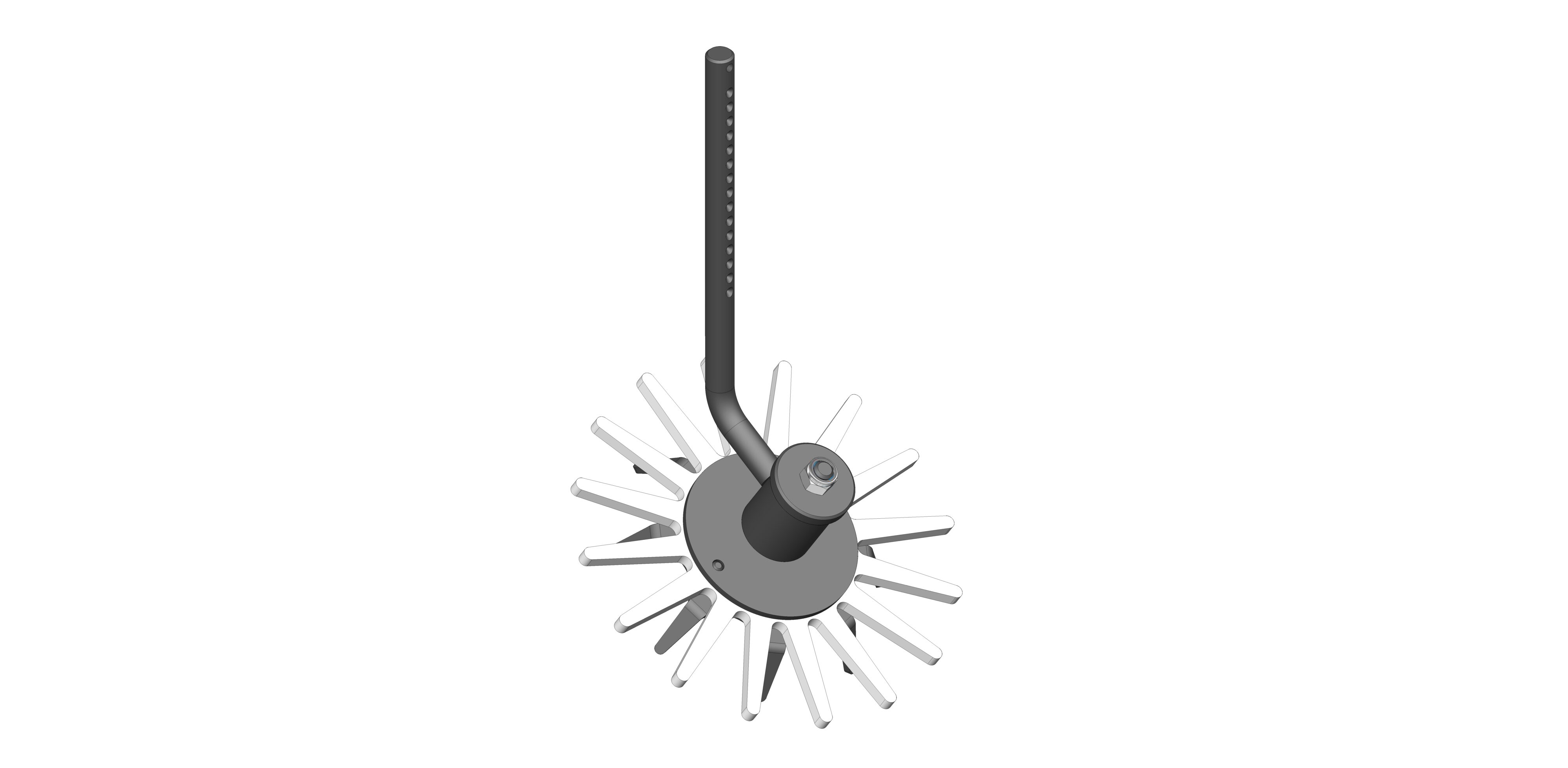

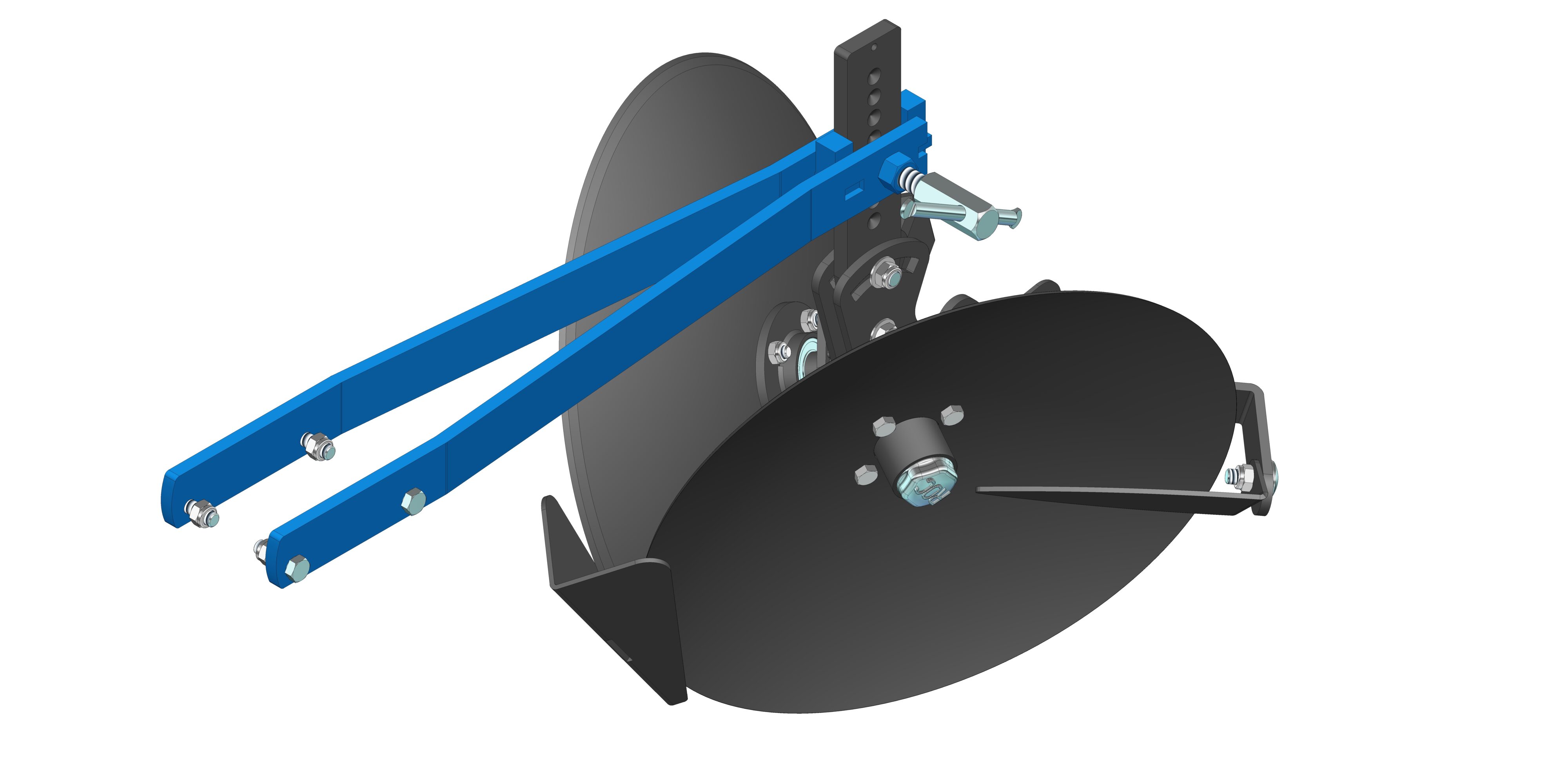

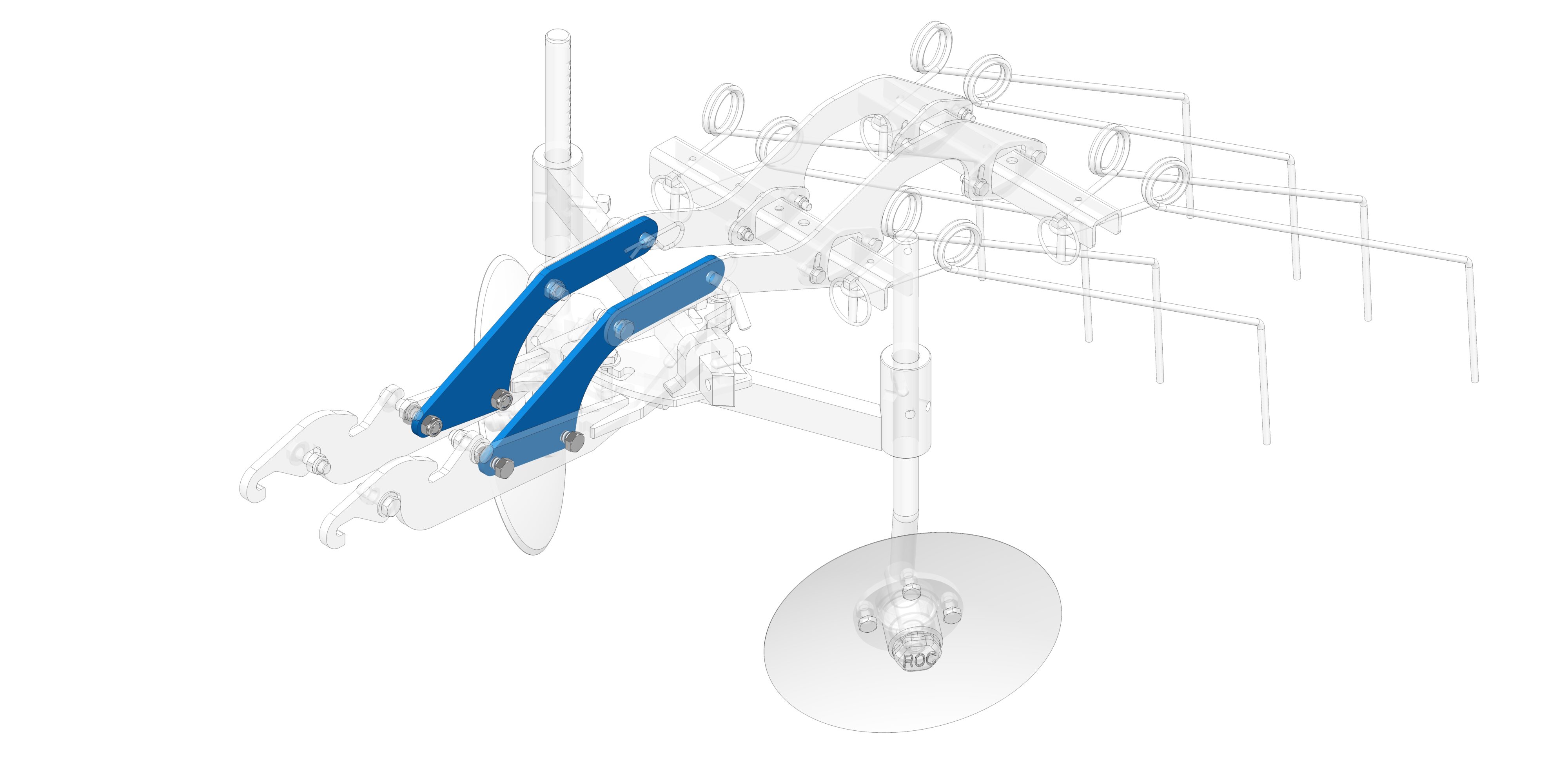

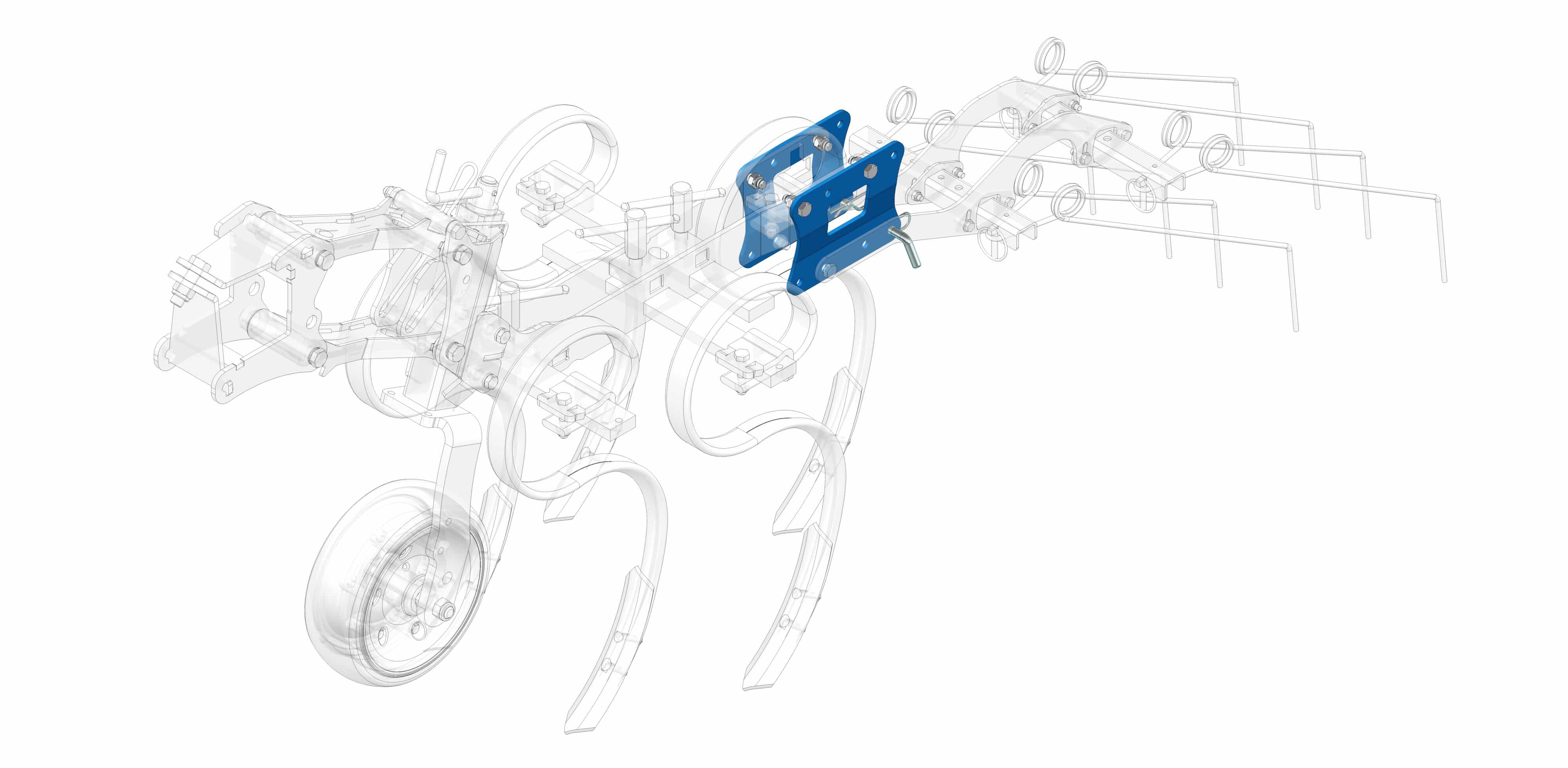

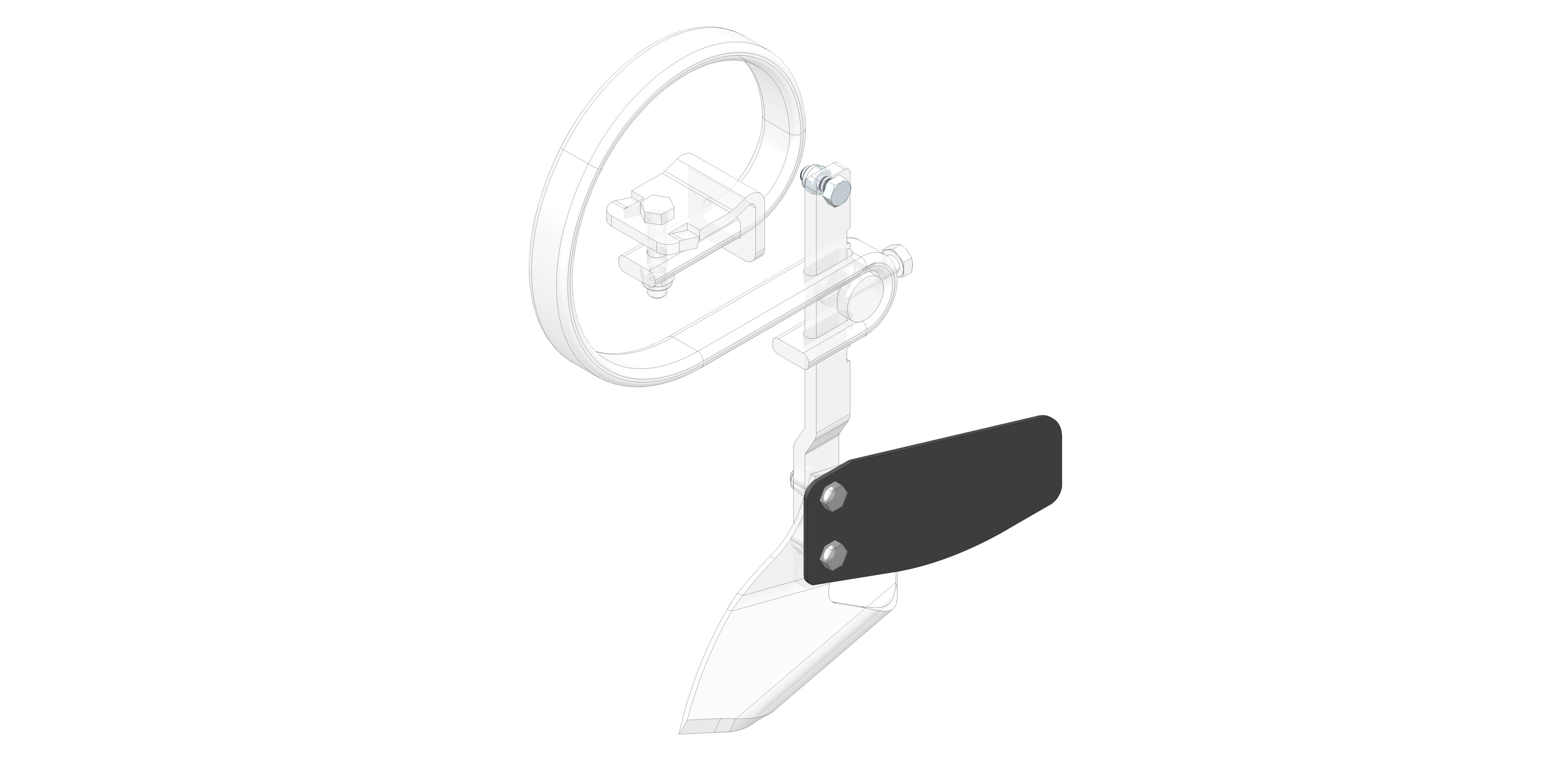

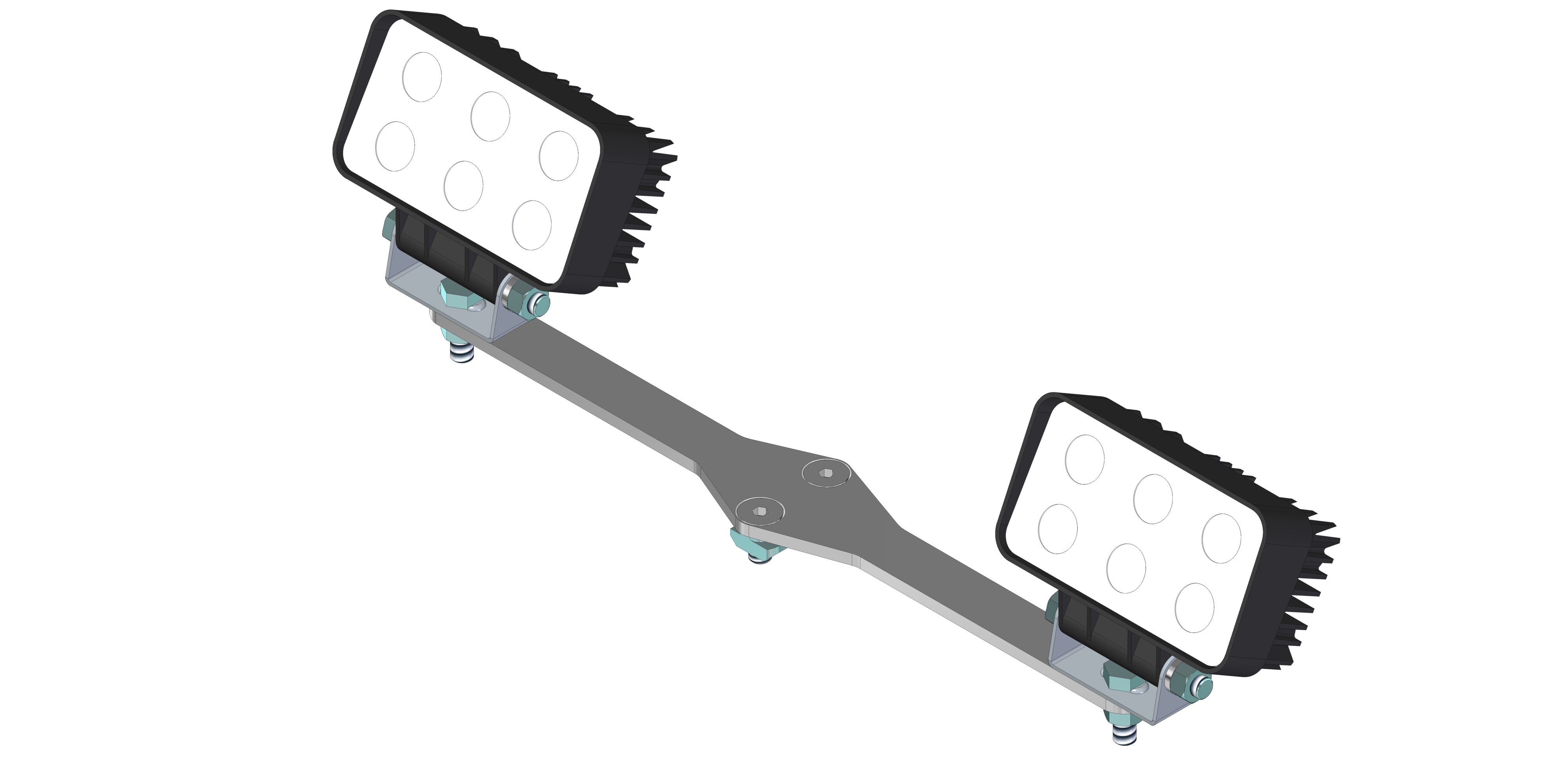

Choose the appropriate guiding system: Camera, Contact tip or both combined.

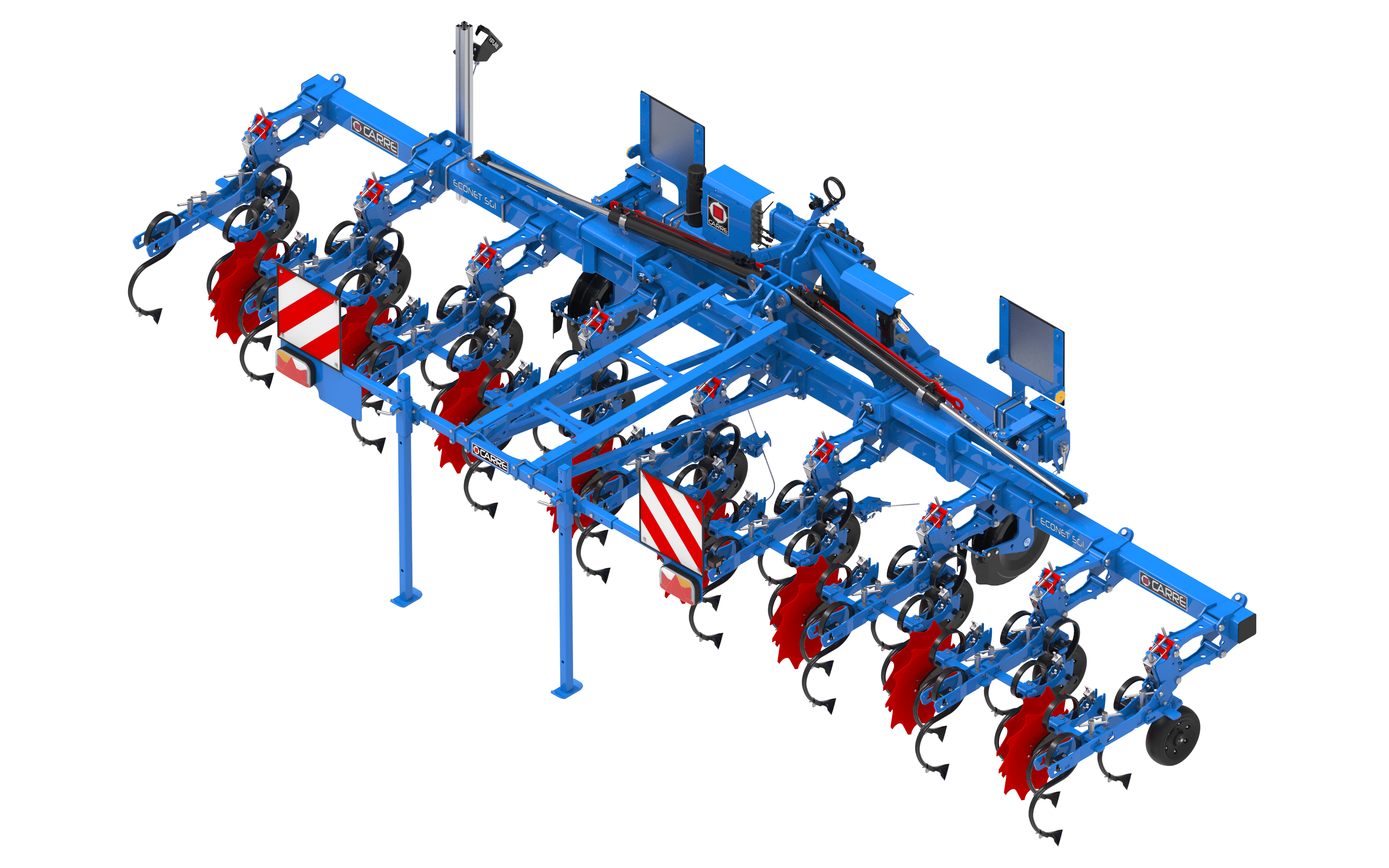

Available from 6 to 18 rows !