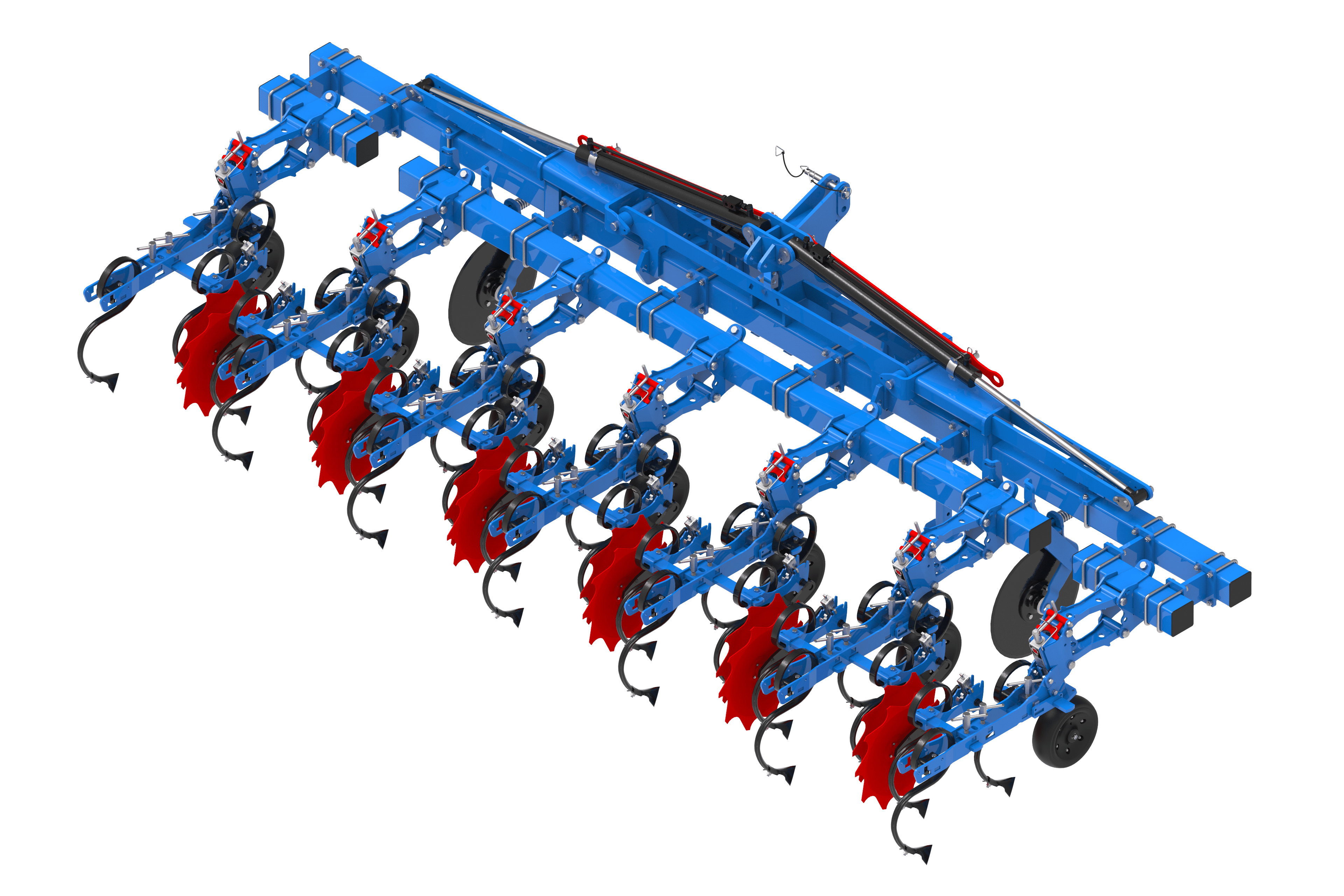

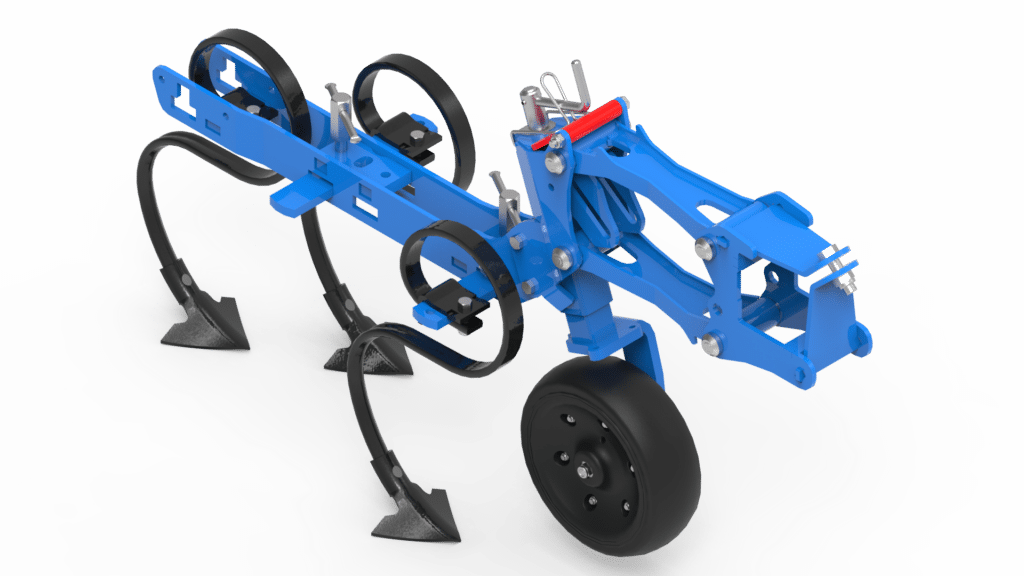

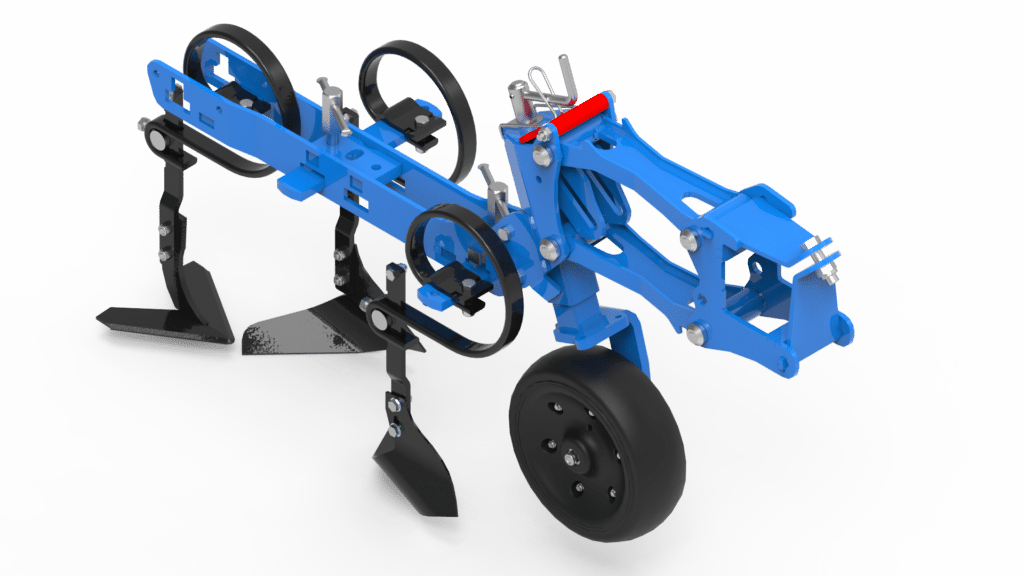

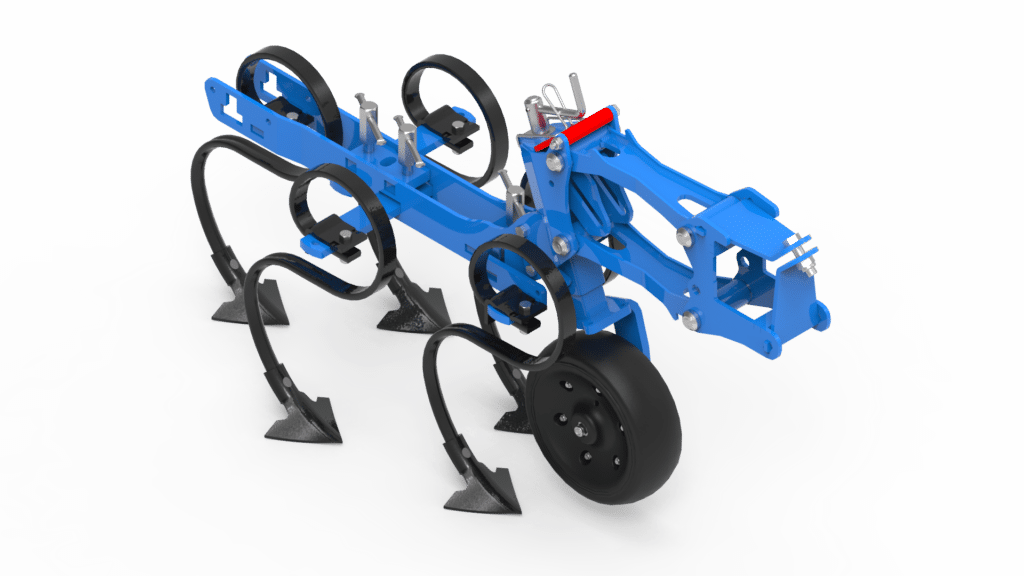

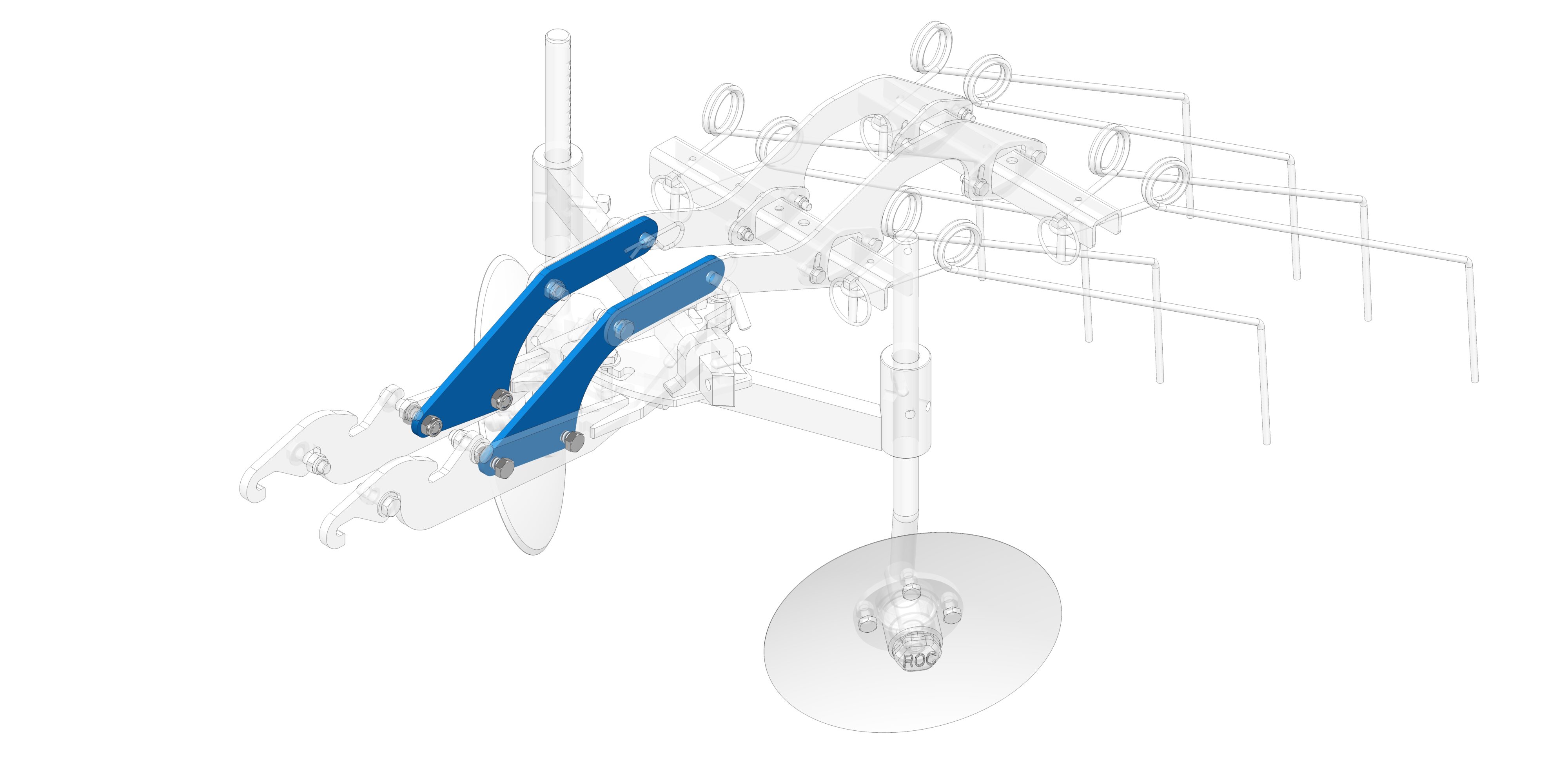

These machines are ideal for those who have several crops to hoe, with variable row spacing.

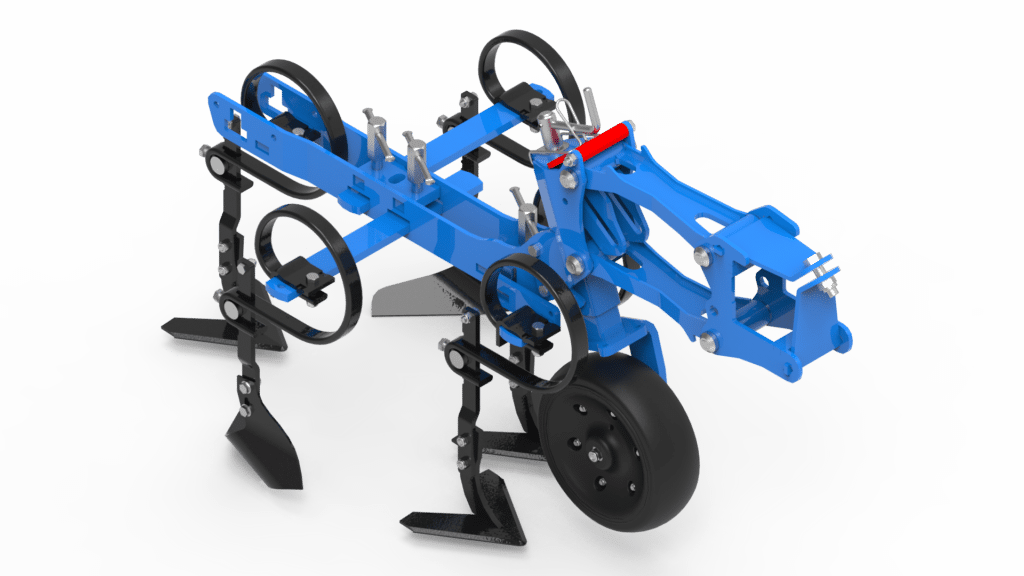

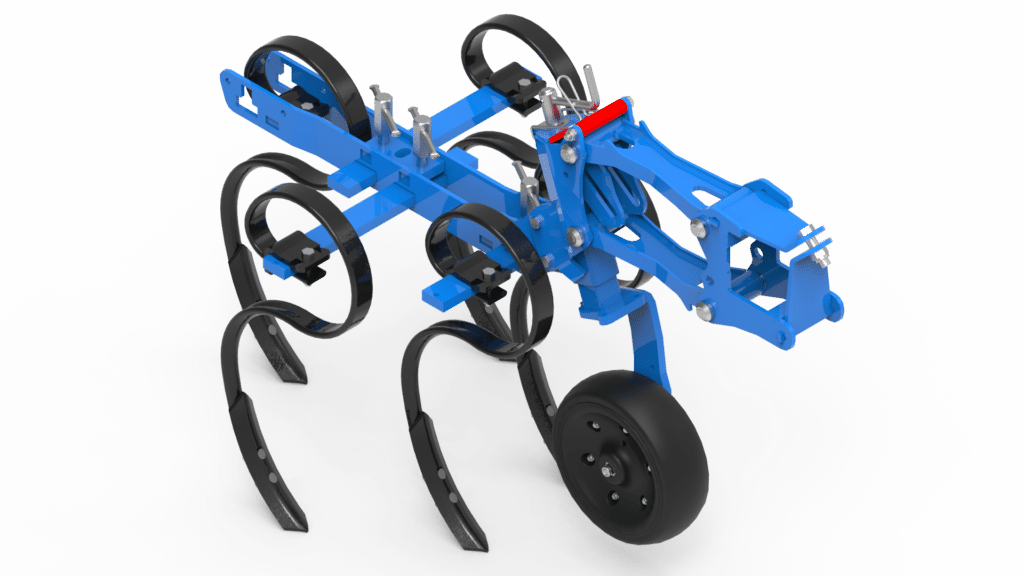

The double-beam system allows great modularity in the positioning of the elements on the beam.

Available from 6 to 12 rows!

These machines are ideal for those who have several crops to hoe, with variable row spacing.

The double-beam system allows great modularity in the positioning of the elements on the beam.

Available from 6 to 12 rows!

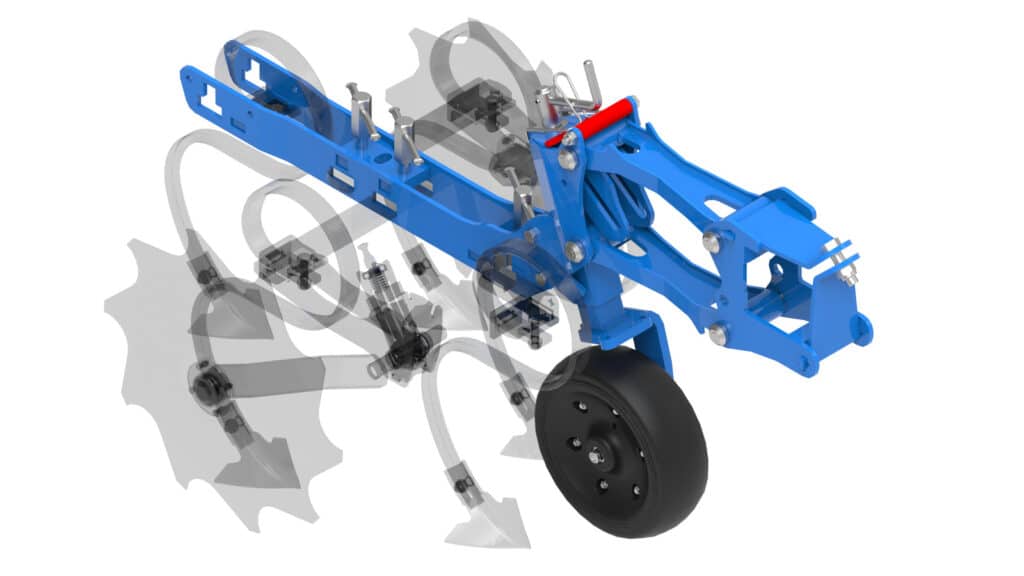

Double hydraulic-mechanical locking system (transport and work)

Double hydraulic-mechanical locking system (transport and work)

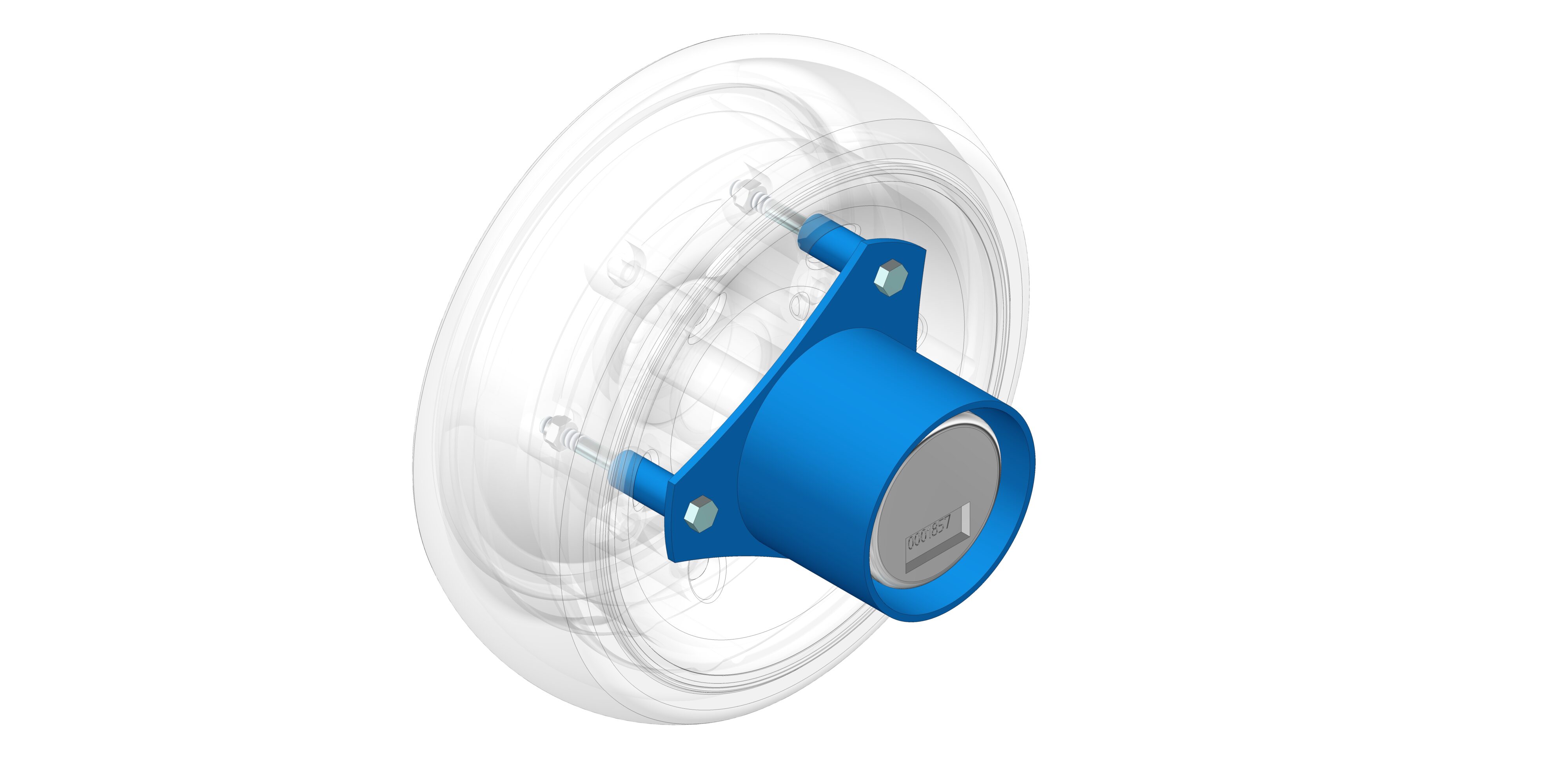

Find your machine’s registration number in the instruction manual, or on the number plate affixed to the machine:

| Number of rows | Spacing (cm) | Recommended elements | Power (Hp) | Weight (Kg)* |

| Sugar Beet | ||||

| 12 | 45-50 | E ou I | 120 | 950 à 1250 |

| Sunflower | ||||

| 7 | 60 | E,I,L ou B | 90 | 850 à 1100 |

| 9 | 110 | 900 à 1300 | ||

| Maize | ||||

| 6 | 75-80 | L ou B | 100 | 800 à 950 |

| 8 | 120 | 950 à 1200 | ||

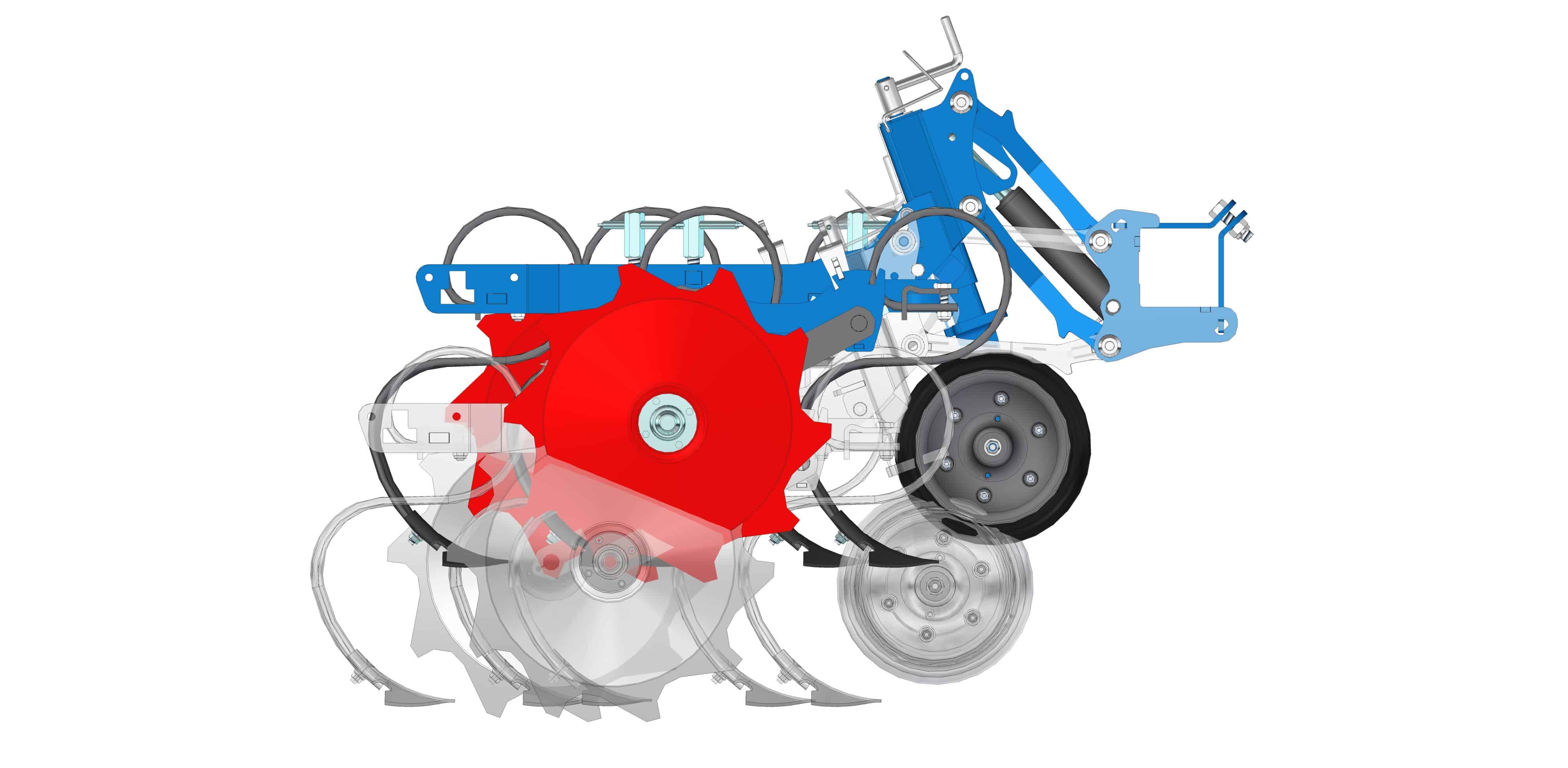

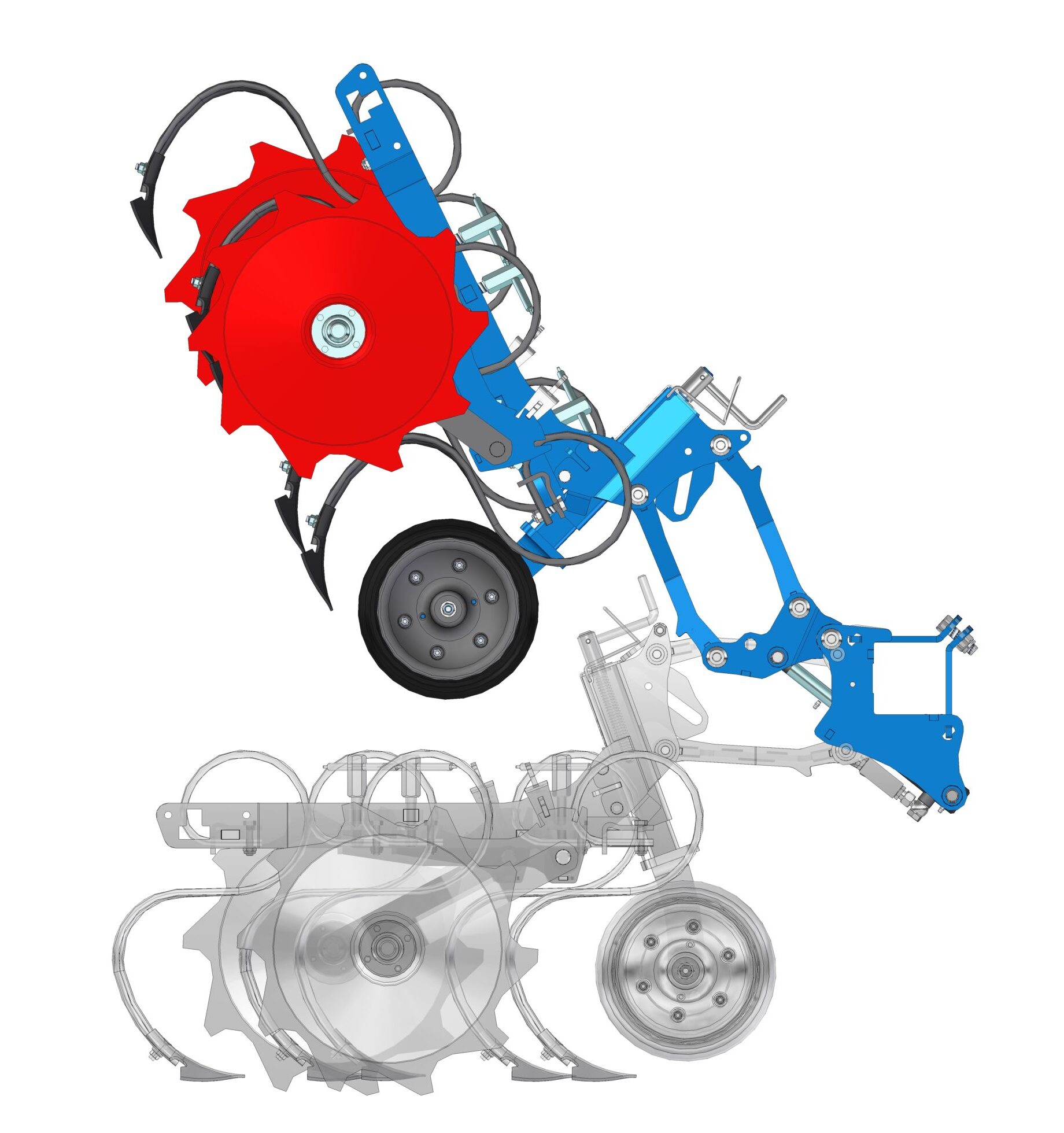

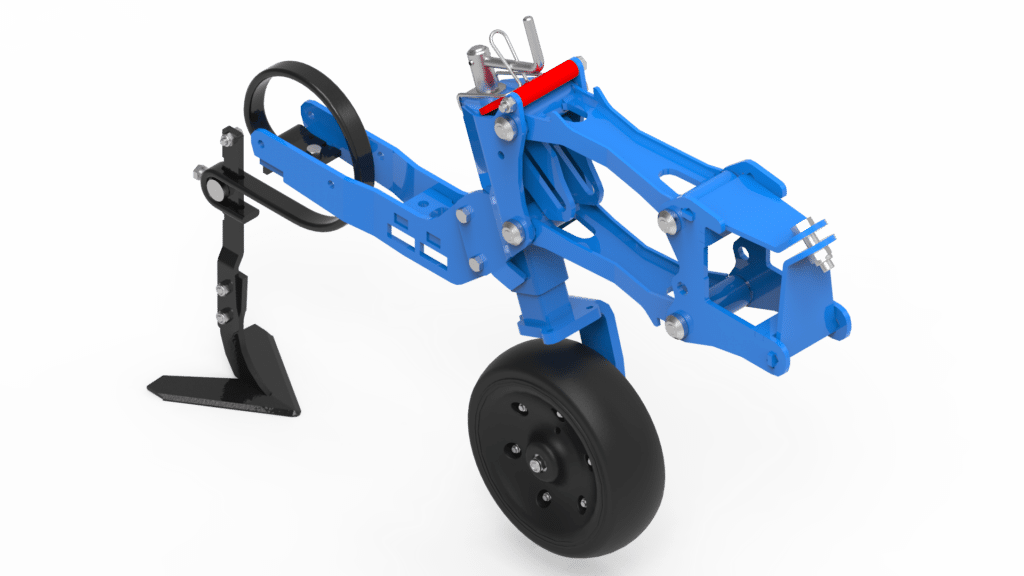

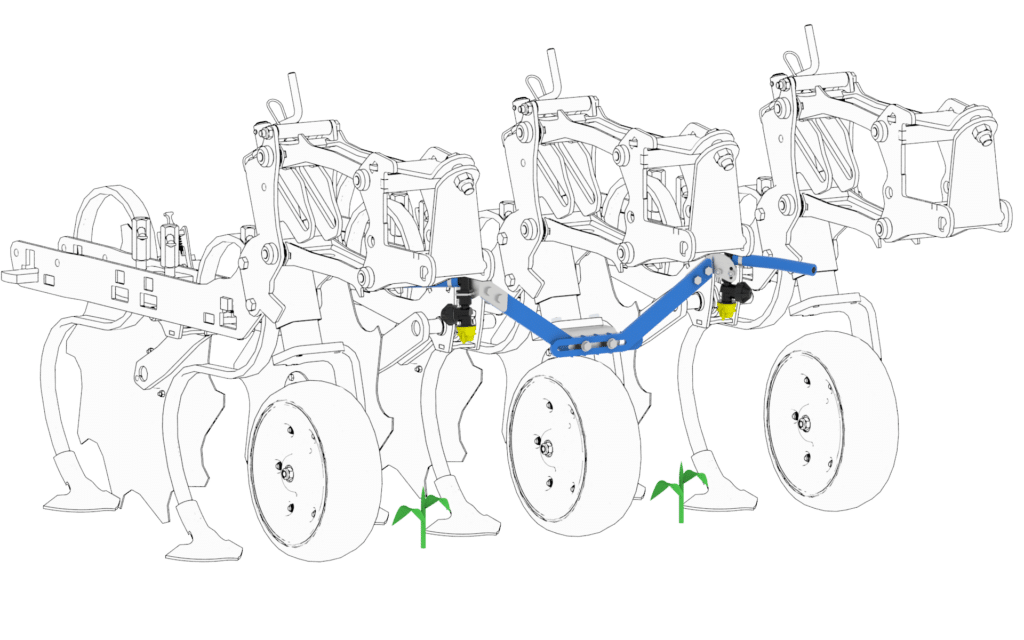

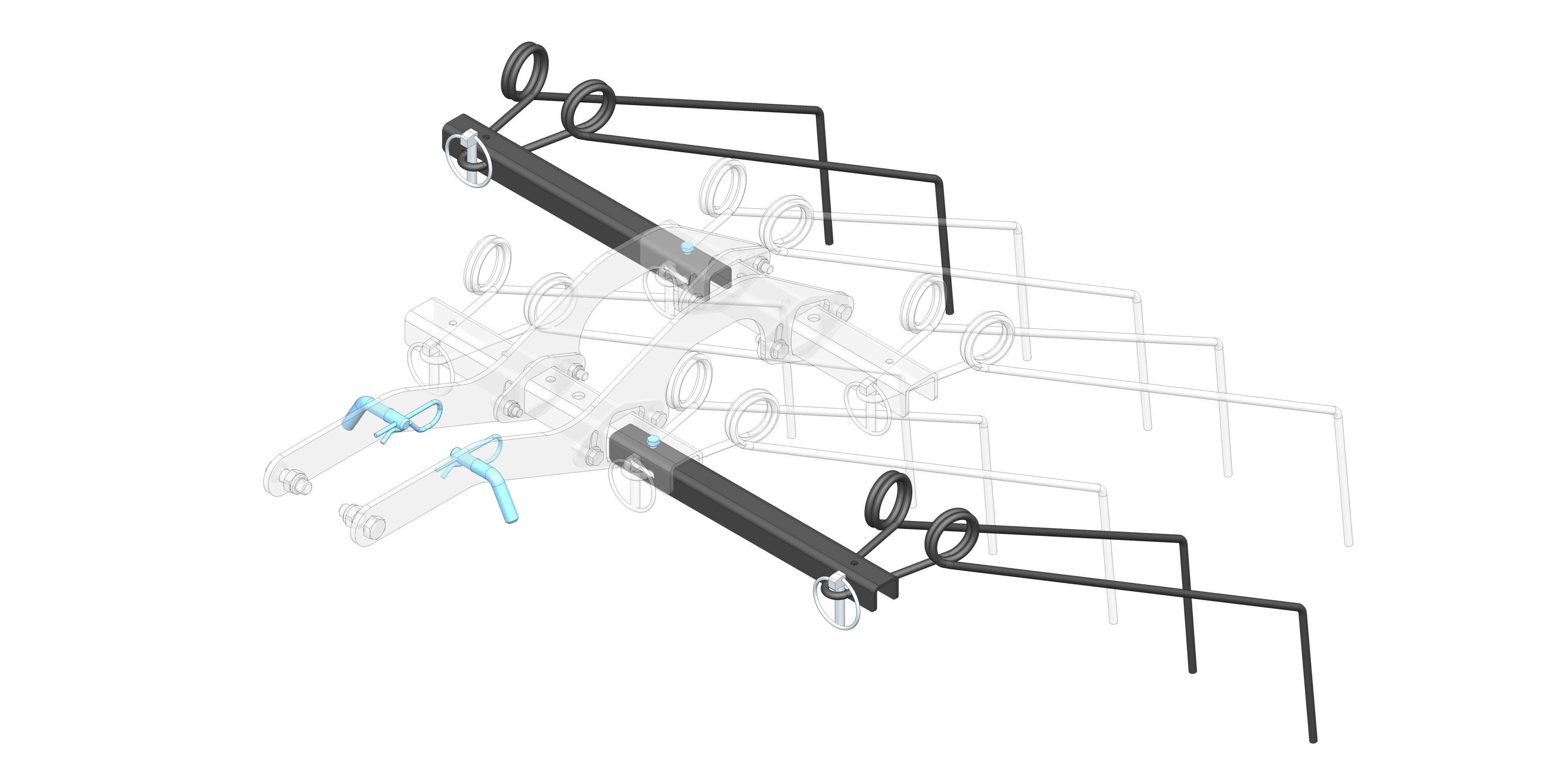

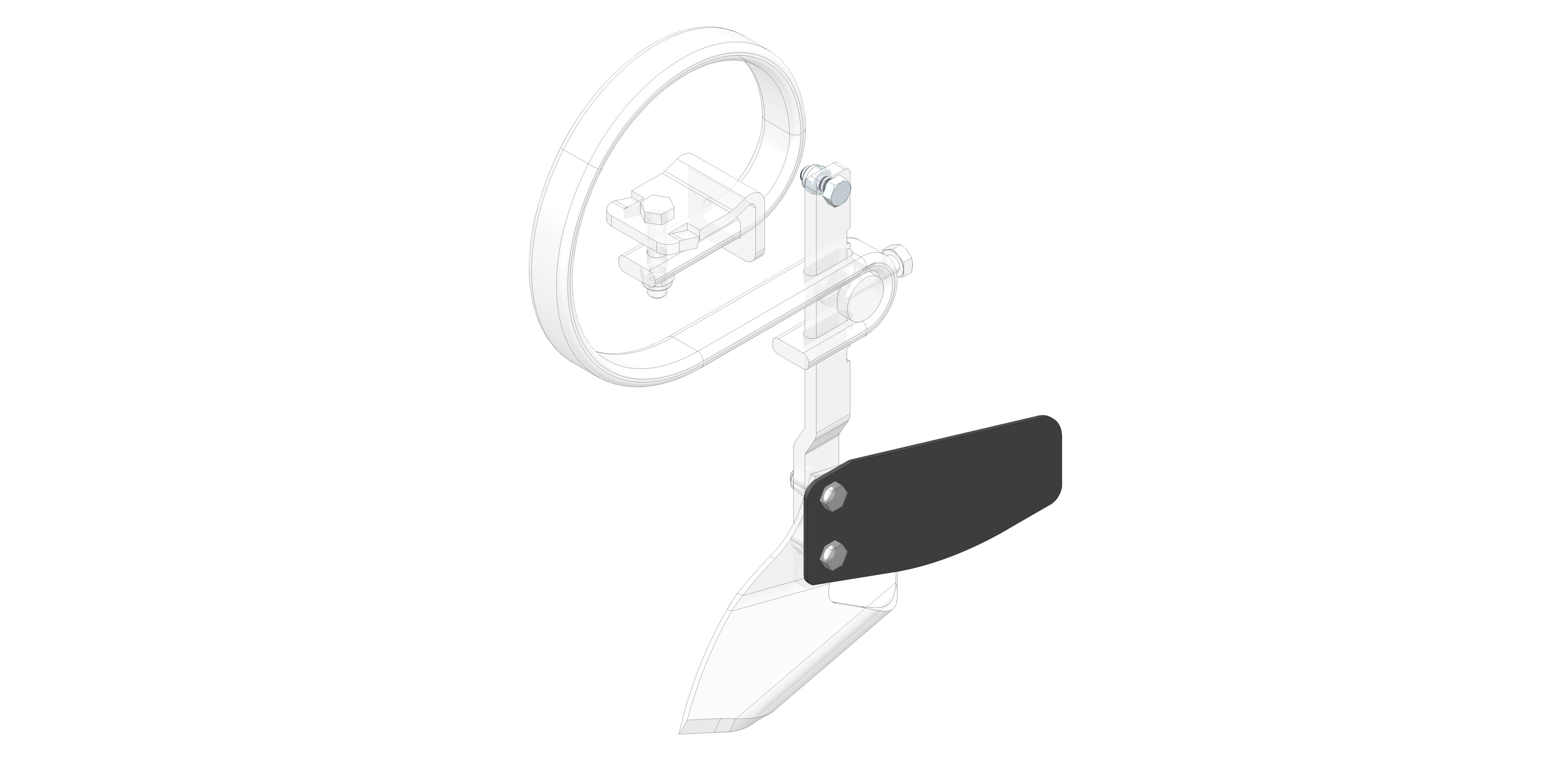

The hoeing element guarantees a constant working depth over the whole width of the cultivator

thanks to the amplitude of oscillation of its parallelogram and its independent grounding wheel.

Robust and maintenance-free design, it adapts to all row crops using its quick setting systems. A wide choice of tines and options to insure an efficient and accurate work.

LIGHT WEEDER ELEMENT: ALL CROPS

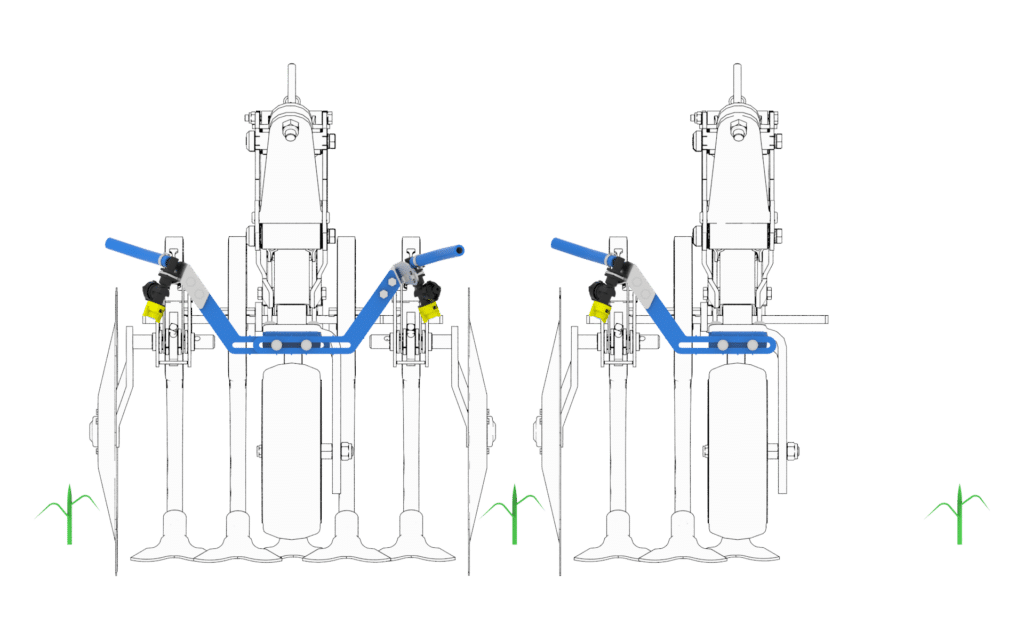

2 hydraulic lifting versions

Version with 23cm horizontal raising from the work position

Version with 52cm vertical raising from the work position

Clearance under chassis 60 to 75cm. For use at a grown crop stage.

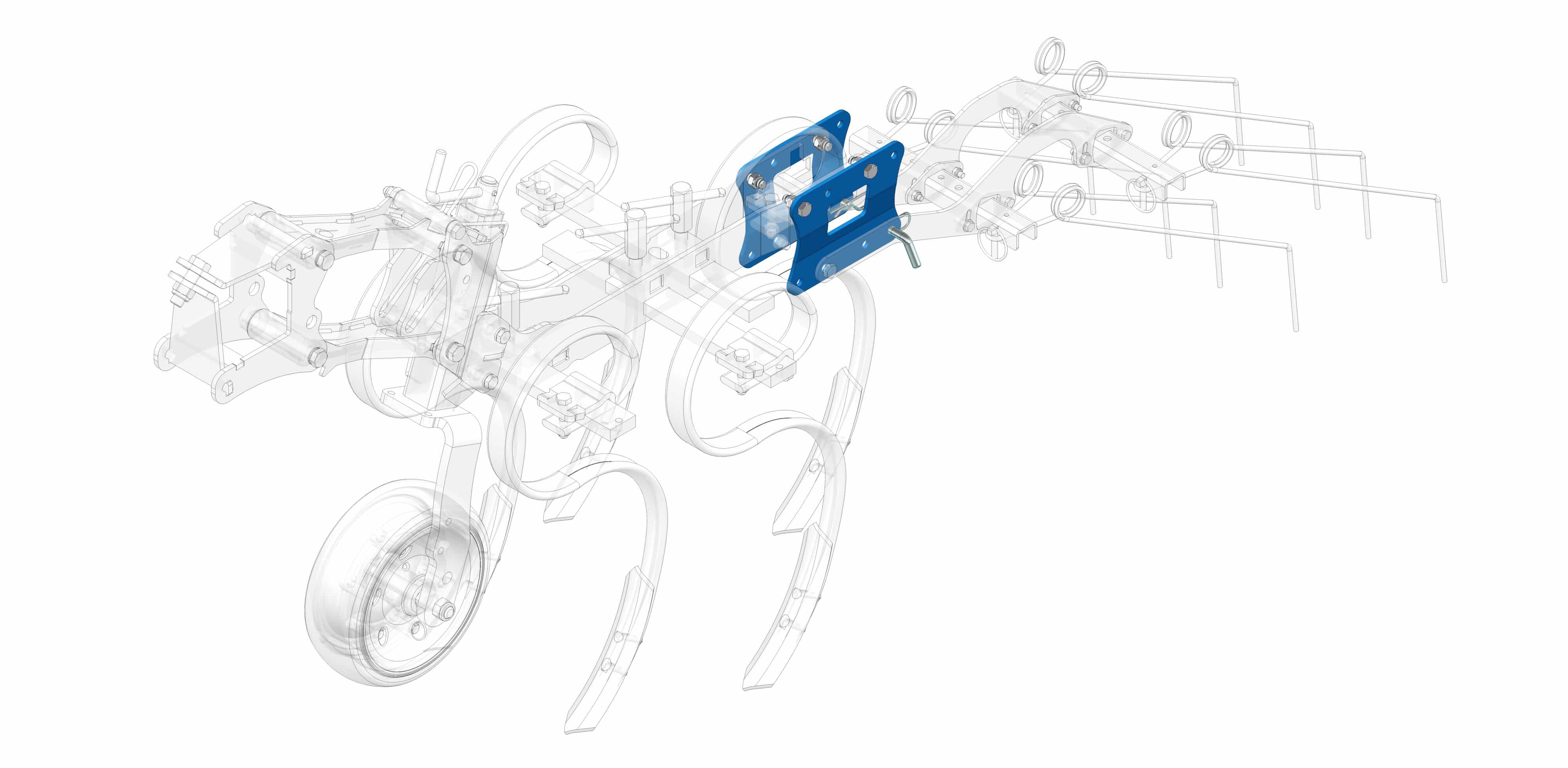

ELEMENT E

For inter-rows spacing from 45 to 60cm

Versatile on all type of soils

3 tines 32x12mm

Triangular ploughshare 150mm

Several ploughshare width in option

ELEMENT I

For inter-rows spacing from 45 to 60cm

Suitable for sandy or silt clay soil

To cut-off with accuracy

32X12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

L blades right and left

ELEMENT C

For inter-row distances from 15 to 30cm

1 element for hoeing 1, 2 or 3 crop rows

To cut-off with accuracy

From 1 to 3 32×12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

ELEMENT L

For inter-rows from 60 to 80 cm

Versatile on all type of soils

5 tines 32x12mm

Triangular ploughshare 150mm

Several ploughshare width in option

ELEMENT B

For inter-rows from 60 to 80 cm

Suitable for sandy or silt clay soil

To cut-off with accuracy

5 32X12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

L blades right and left

ELEMENT X

For inter-rows from 60cm

To work up to 10cm depth

Suitable for hard stony soil condition

5 tines 45x12mm

Straight reversible ploughshare

Triangular shares optional – W element

Curved 32X12 tine with :

– Triangular duckfoot 70, 105,

150, 175, 200 or 250mm

– Reversible straight share

Rigid fitted 32x12mm tin adjustable with its 50 to 300mm wide triangular plough share

32×12 tine with adjustable rigid holder and right or left L blade

Large clearance 45x12mm tine with :

– Reversible straight share

– Triangular ploughshare 150, 175, 200 or 250mm

Retractable discs crop guard Ø500mm suitable for all conditions. Compatible with elements type E, L and X

Long retractable plant protector for optimal crop protection. Compatible with elements type E, L and X

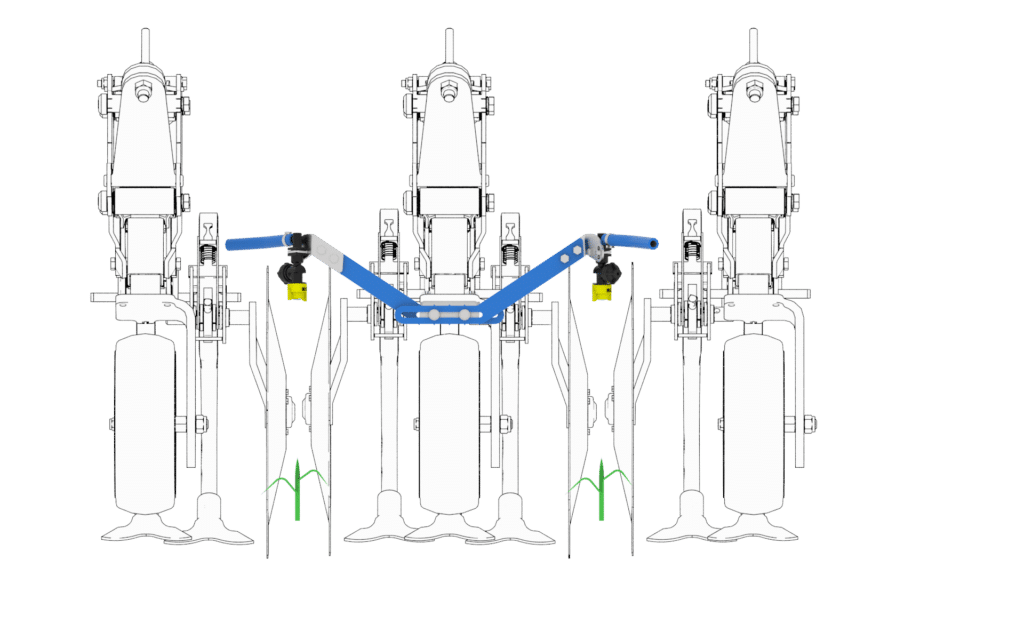

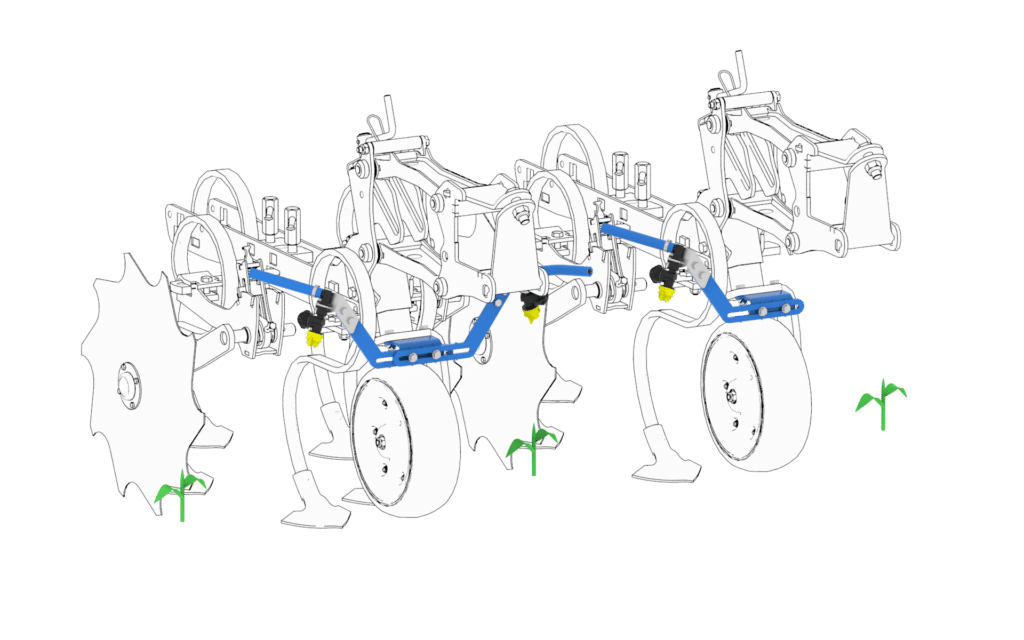

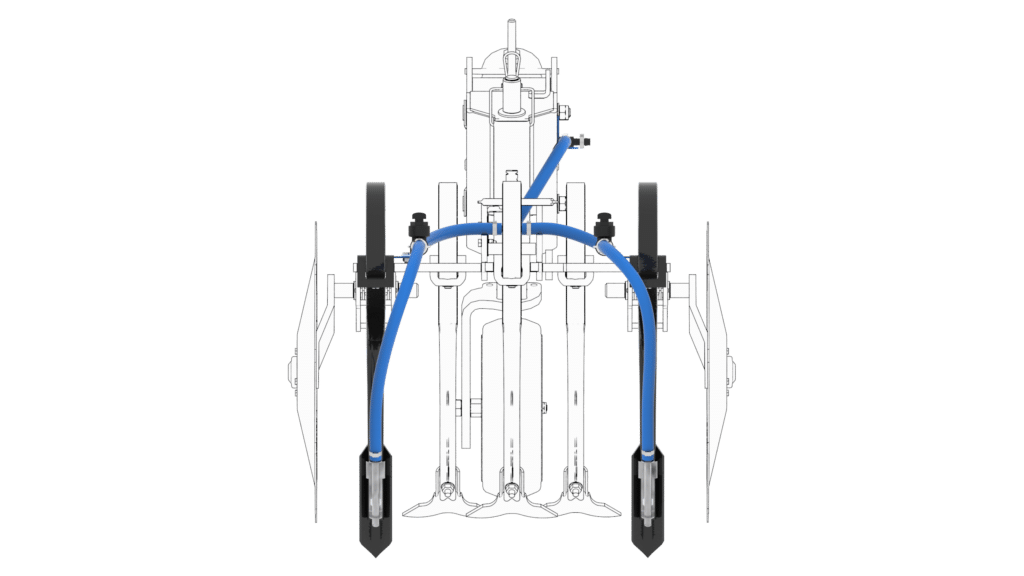

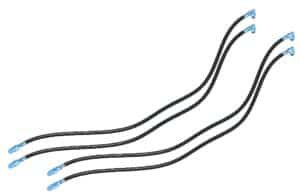

SPRAY KIT : Localised liquid fertilising and spraying!

Piping protection tamp over the entire machine.

Quick coupling on Ø18mm central output

Spraying over the 1 jet row

Stainless steel flat jet 40° with drip plate

Flow rate from 40 to 150 L/ha

Spraying on the 2-jet row

Stainless steel flat jet 40° with drip plate

Flow rate from 40 to 150 L/ha

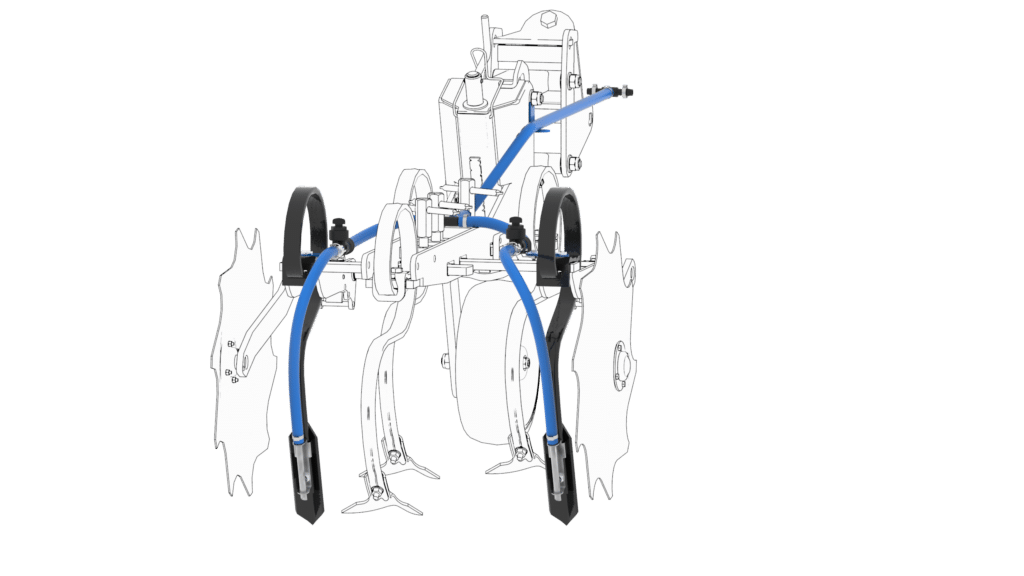

Fertilisation with injector on either side of the row

St. steel strip till mounted on straight tines 38x12mm

St. steel disc Ø1 / 1.5mm with integrated anti-drip and shut-off valve

Flow rate from 80 to 400 L/ha

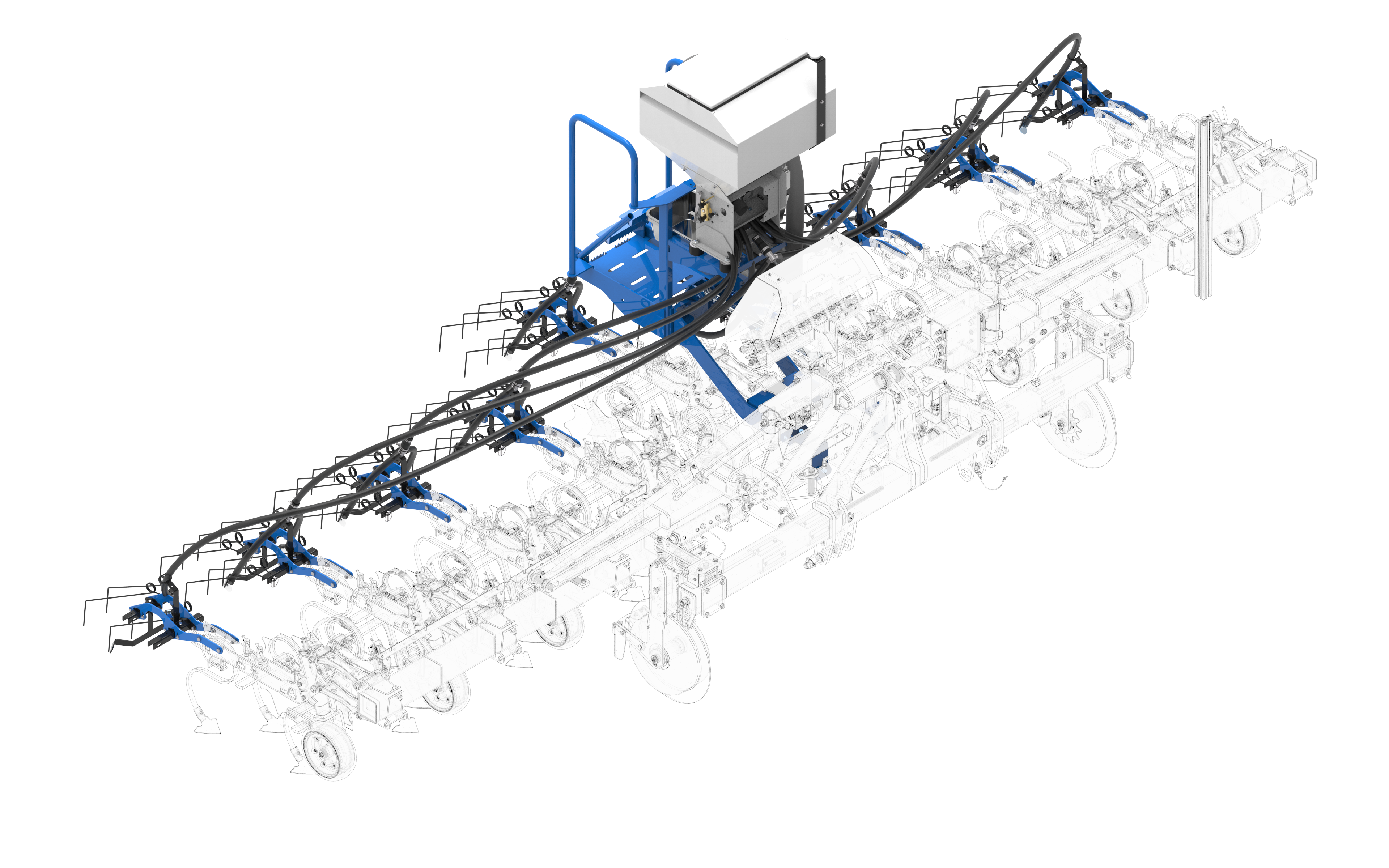

Sowing seed by surface broadcasting at the same time of hoeing

LIMIT SOIL EROSION AND TRAP NITRATE !

2 metering rollers for small and large seeds

8-flute distributor. For row spacing from 45 to 80 cm up to 12 rows

2 nozzles per row followed by 4 double combs

GPS-controlled control unit

Solid fertilization localized

THE GOOD DOSIS AT THE RIGHT TIME IN THE RIGHT PLACE !

For FRONT HOPPER : solid fertilisation localizer

WEIGHT BALANCE AND ACCURATE DOSING !

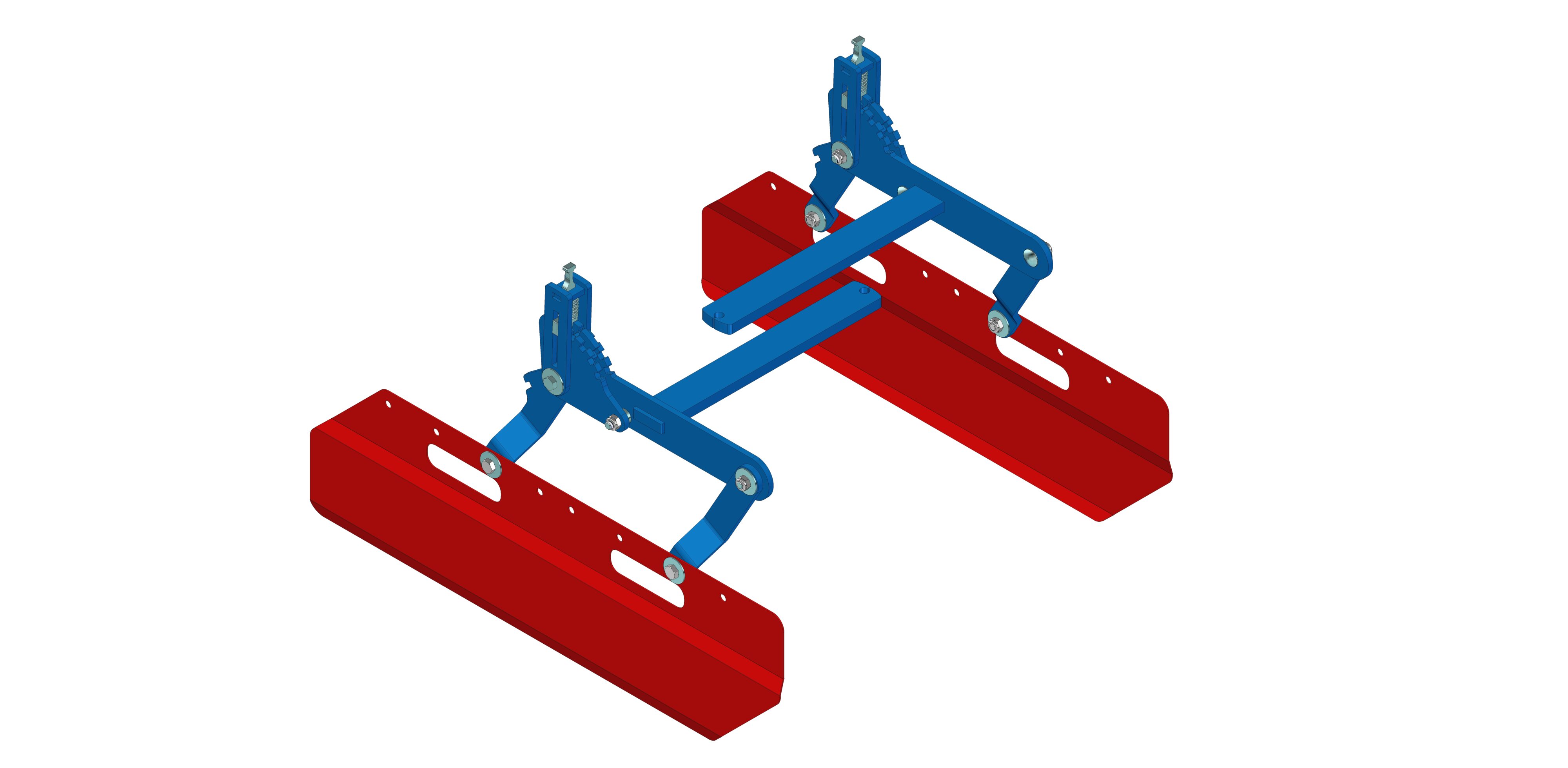

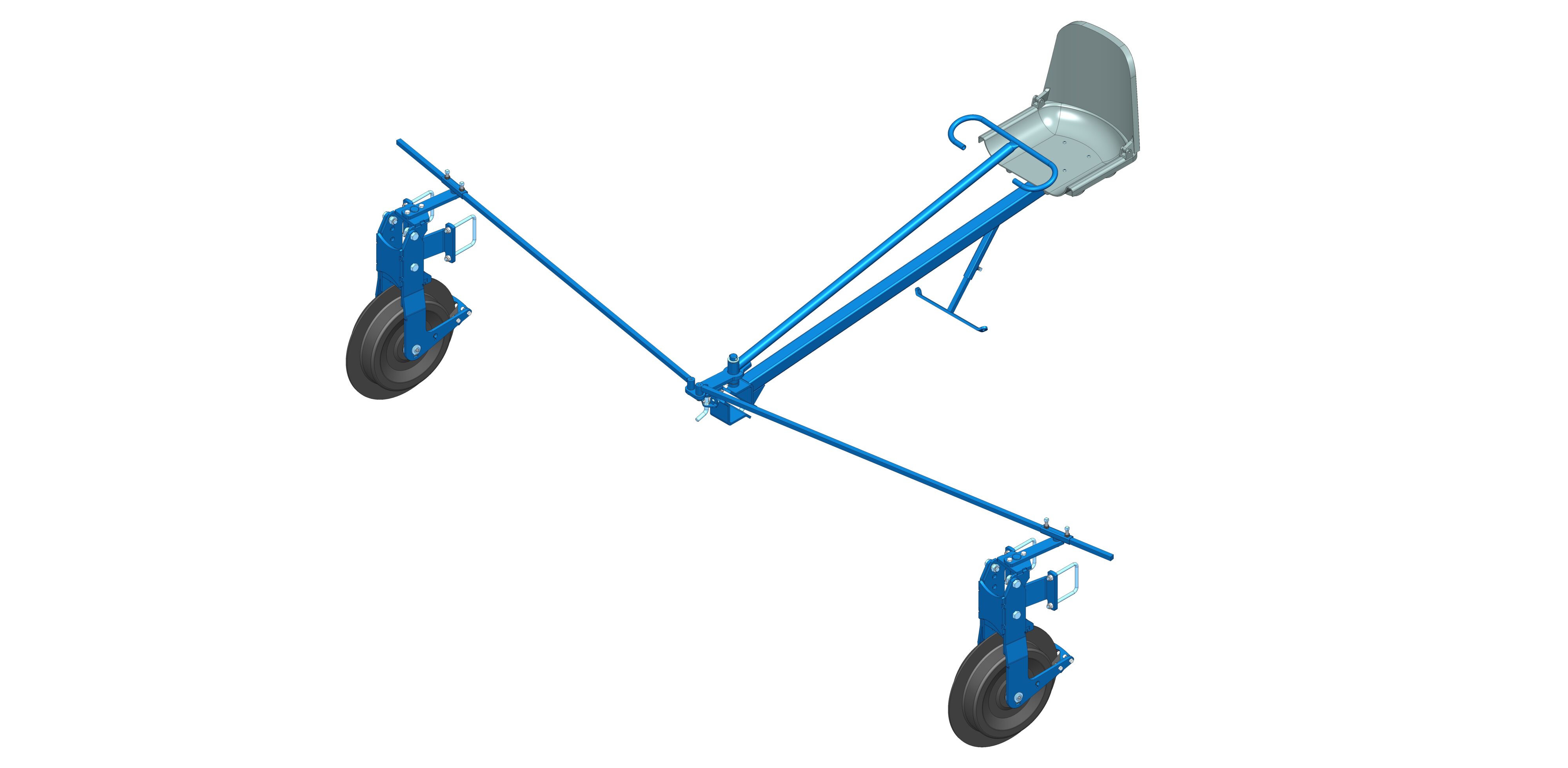

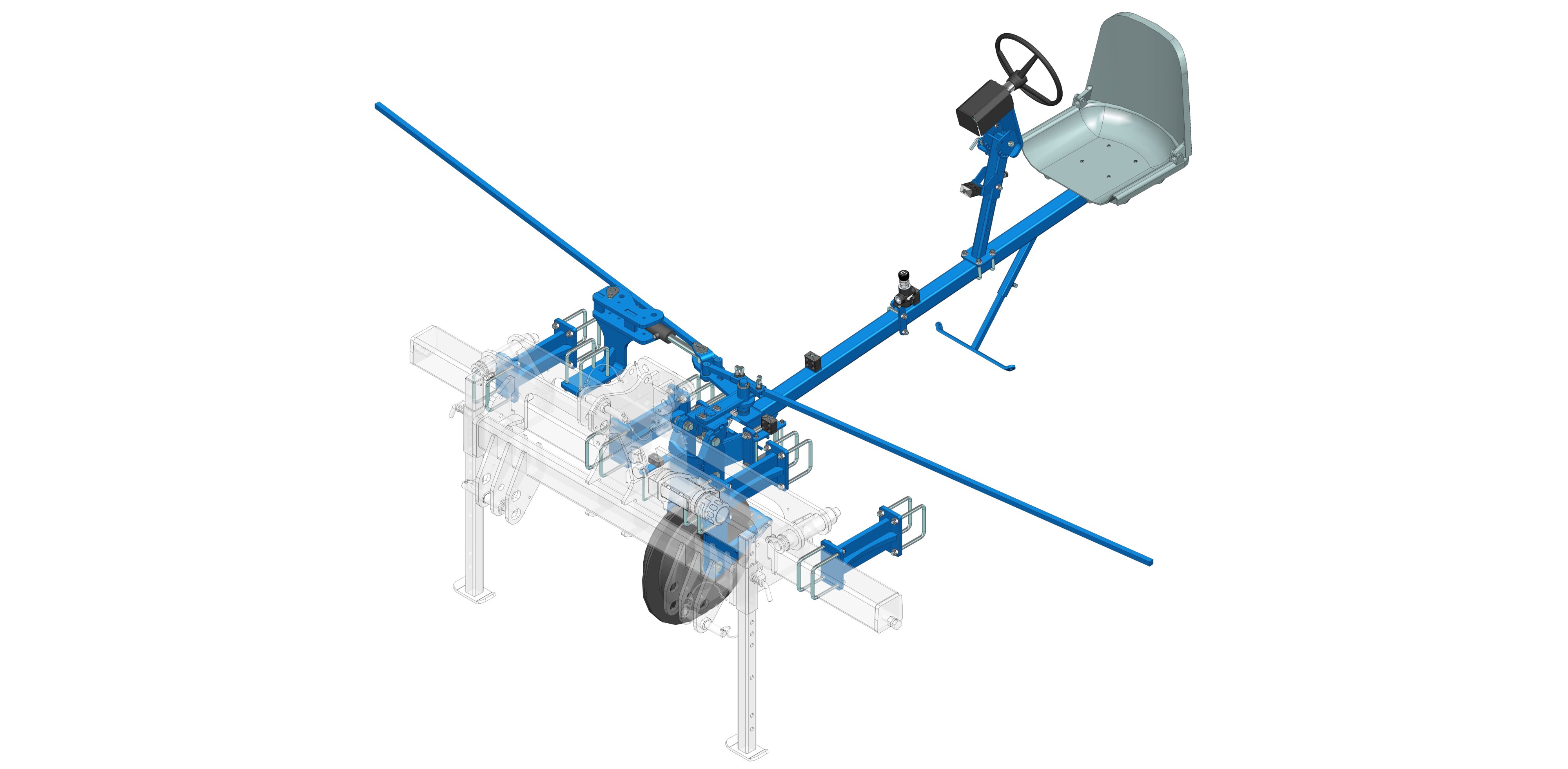

Front Mounting Hitch

Bracket for the fixing of the tracking’s

modul or seat

Seat to fix on the bracket

Steering with flanged or castor wheels

Hydraulic assistance on manual guidance

Independent hydraulic folding

of the extensions

Ridging ploughshare 350mm

L, B or X

Ridging ploughshare 600mm

with adjustable wings

L, B or X

Discs Ø300mm

L, B or X

NETLINE Ø360mm star for fitting on

Ø300 disc holder

L, B or X

Discs Ø510mm

L, B or X

Comb harrow in the inter-row

Comb harrow on the row

Adaptation for combination

of discs Ø300mm and comb harrow

Comb lowering kit if XL element

Surface measurement kit on wheel

Deflector for L blade

I and B

Opening discs Ø300mm

Pressure spring kit

Hydraulic lifting of horizontal hoe

elements

Hydraulic lifting of vertical hoe

elements

Depth control wheels 10PR

Ø550x175mm