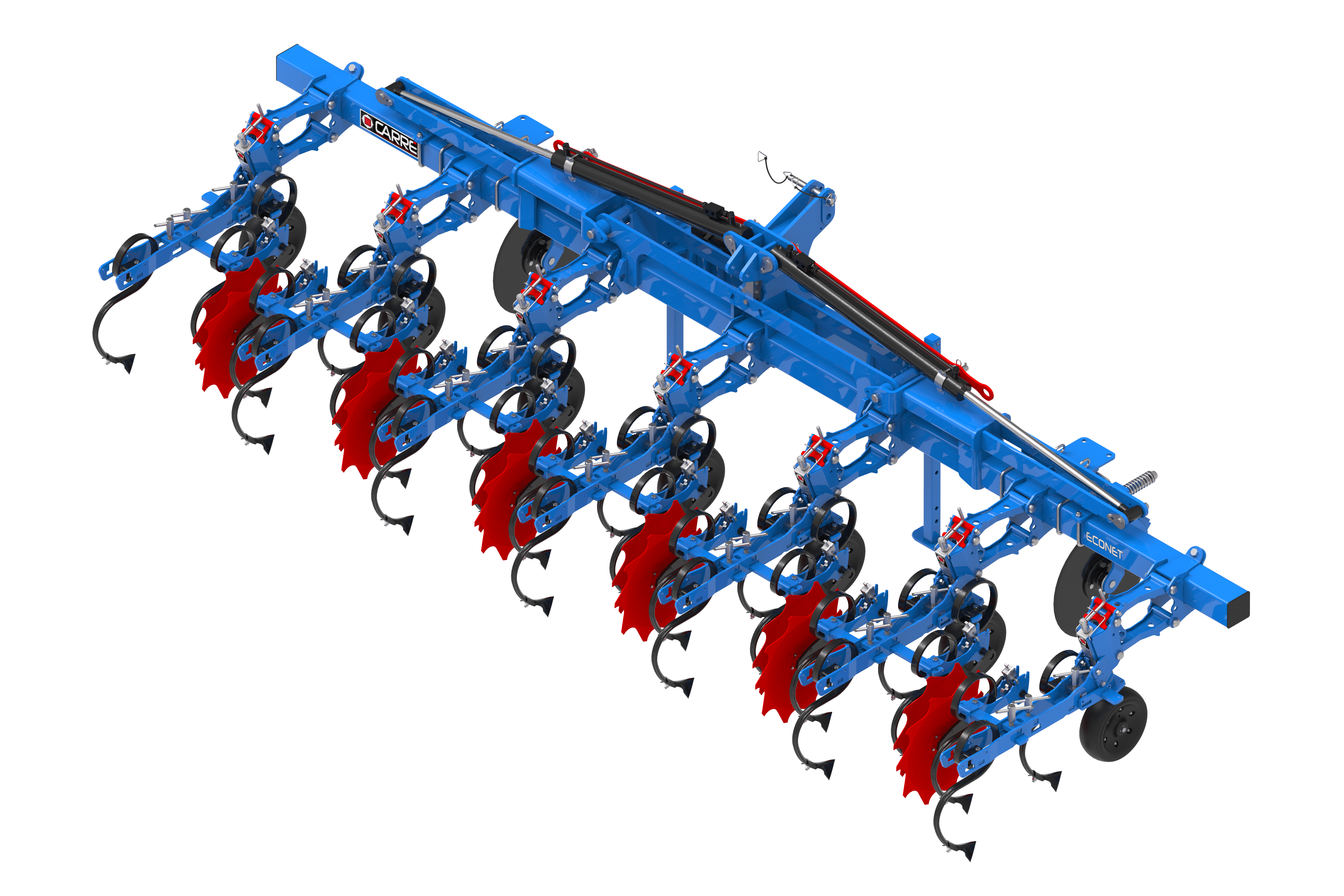

| Number of rows | Spacing (cm) | Recommended elements | Power (Hp) | Weight (Kg)* |

| Sugar Beet | ||||

| 12 | 45-50 | E ou I | 110 | 900 à 1200 |

| 18 | 160 | 2300 à 2800 | ||

| Sunflowers | ||||

| 7 | 60 | E,I,L ou B | 90 | 650 à 1100 |

| 9 | 110 | 750 à 1300 | ||

| Maize | ||||

| 6 | 75-80 | L ou B | 90 | 750 à 950 |

| 8 | 110 | 950 à 1200 | ||

| 12 | 160 | 2200 à 2700 | ||

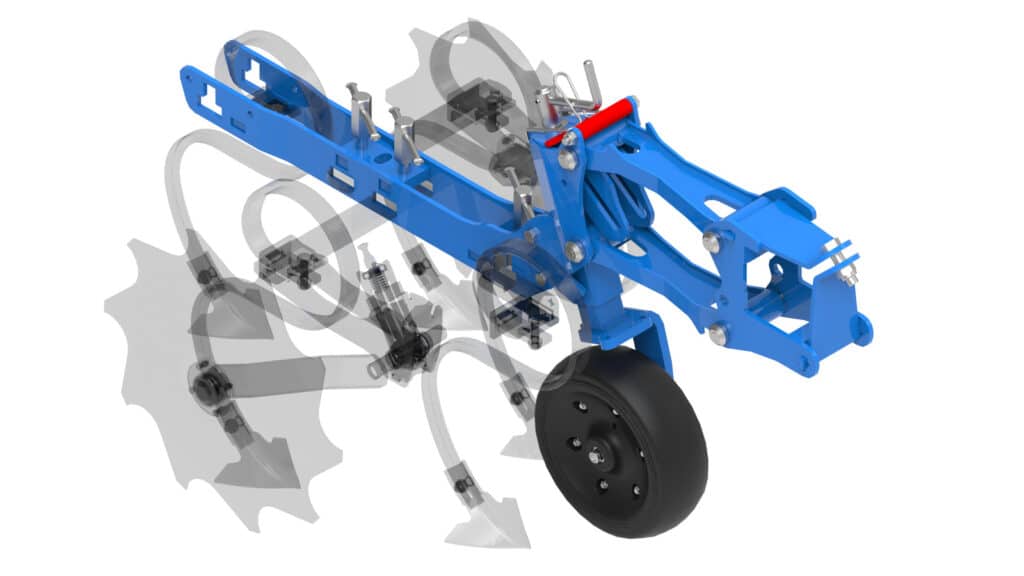

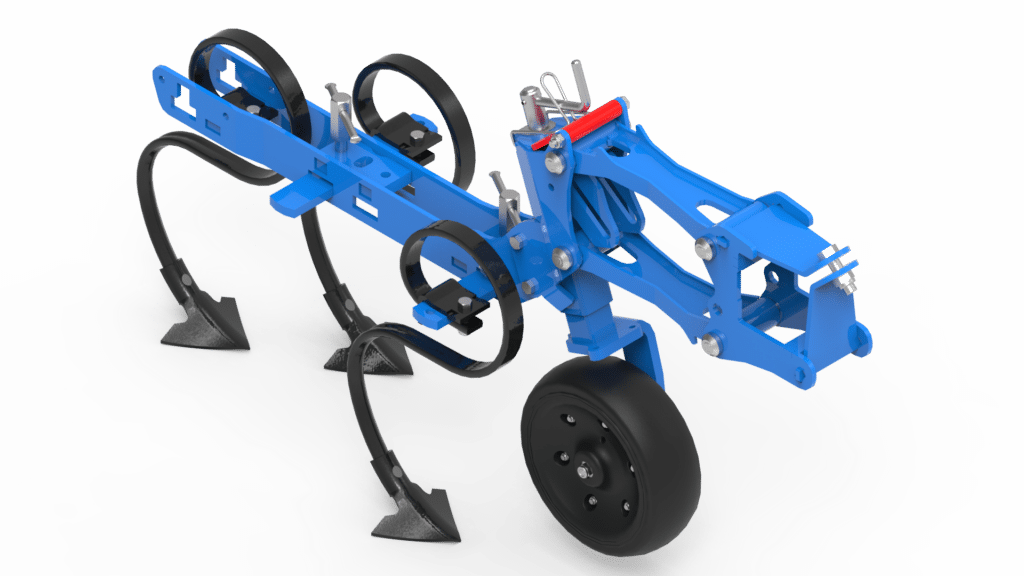

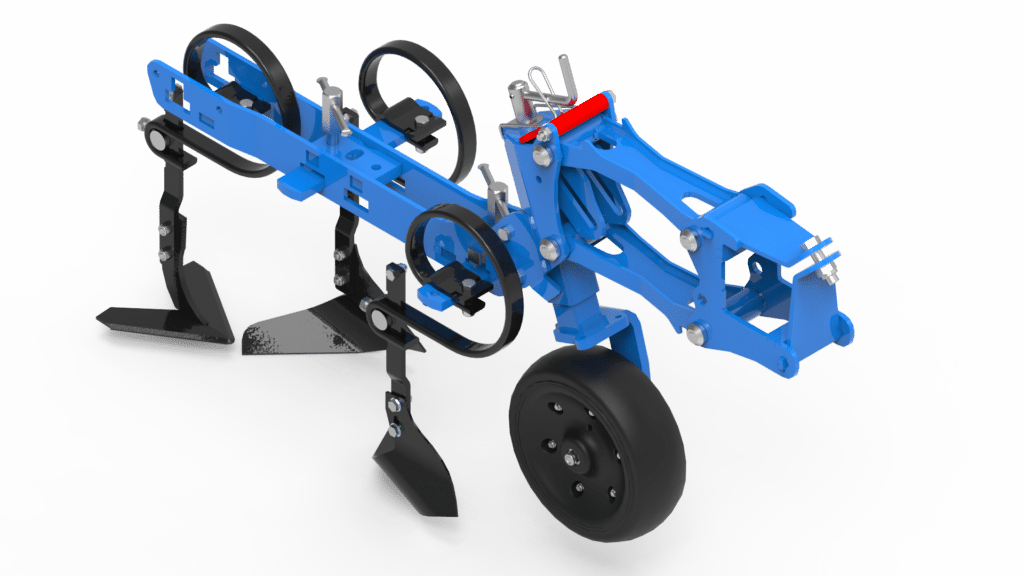

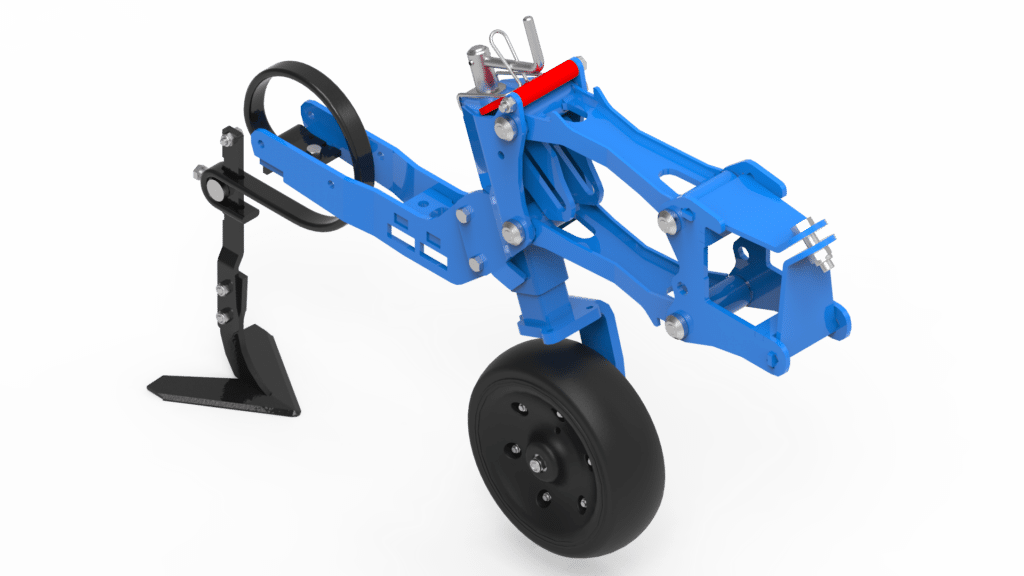

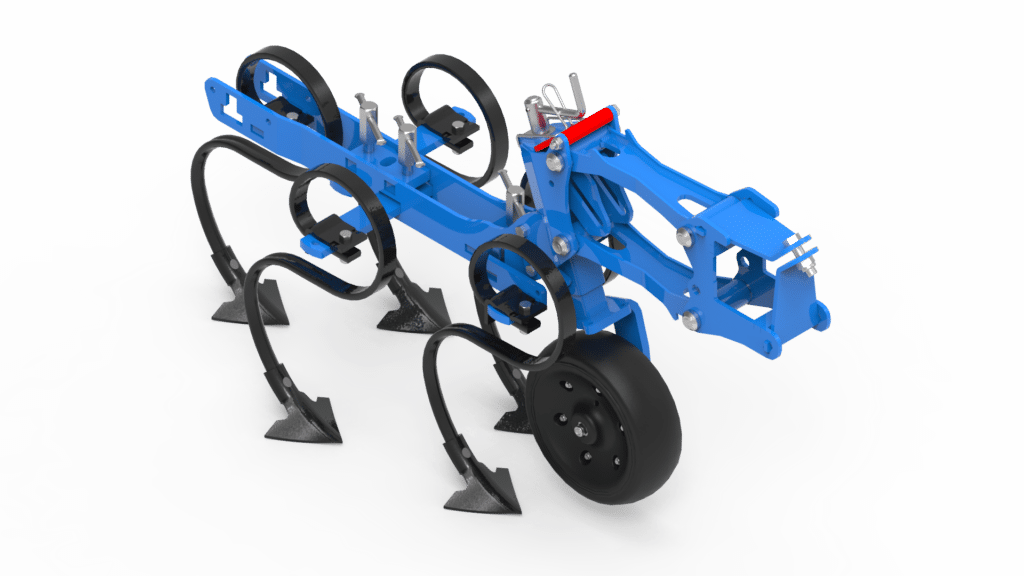

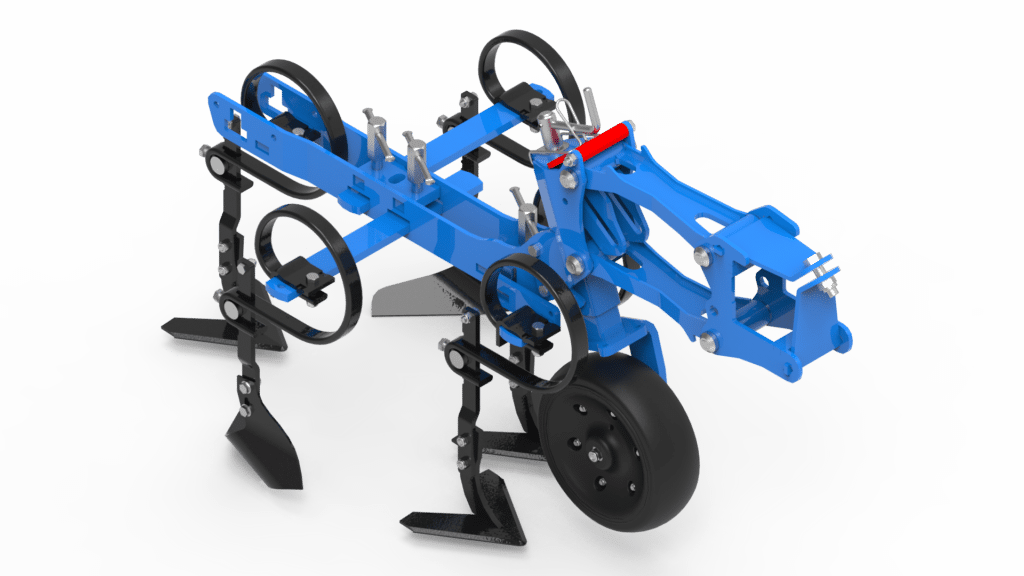

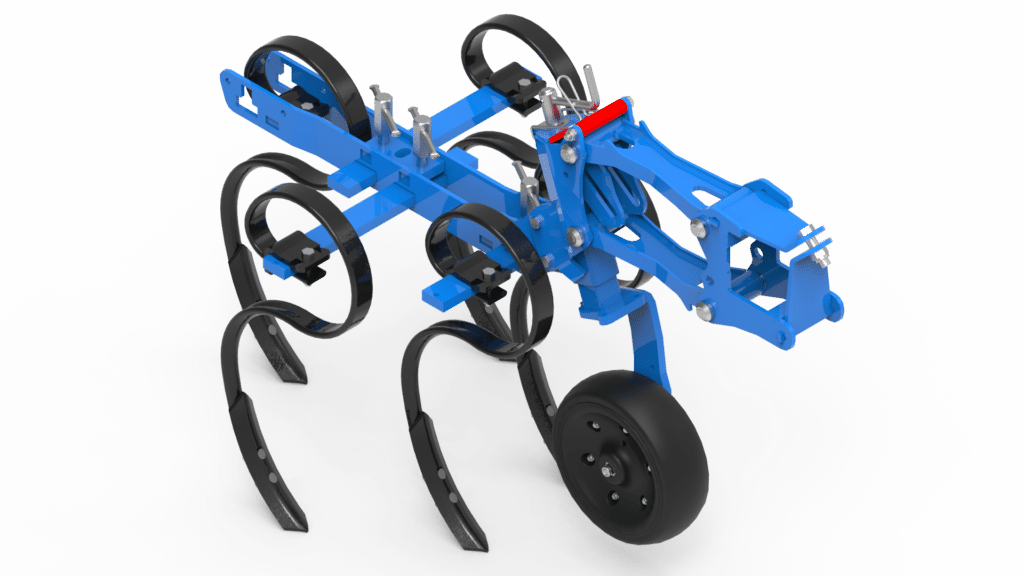

The hoeing element guarantees a constant working depth over the whole width of the cultivator

thanks to the amplitude of oscillation of its parallelogram and its independent grounding wheel.

Robust and maintenance-free design, it adapts to all row crops using its quick setting systems. A wide choice of tines and options to insure an efficient and accurate work.

LIGHT WEEDER ELEMENT: ALL CROPS

2 hydraulic lifting versions

Version with 23cm horizontal raising from the work position

Version with 52cm vertical raising from the work position

Clearance under chassis 60 to 75cm. For use at a grown crop stage.

ELEMENT E

For inter-rows spacing from 45 to 60cm

Versatile on all type of soils

3 tines 32x12mm

Triangular ploughshare 150mm

Several ploughshare width in option

ELEMENT I

For inter-rows spacing from 45 to 60cm

Suitable for sandy or silt clay soil

To cut-off with accuracy

32X12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

L blades right and left

ELEMENT C

For inter-row distances from 15 to 30cm

1 element for hoeing 1, 2 or 3 crop rows

To cut-off with accuracy

From 1 to 3 32×12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

ELEMENT L

For inter-rows from 60 to 80 cm

Versatile on all type of soils

5 tines 32x12mm

Triangular ploughshare 150mm

Several ploughshare width in option

ELEMENT B

For inter-rows from 60 to 80 cm

Suitable for sandy or silt clay soil

To cut-off with accuracy

5 32X12 tines with adjustable rigid holder

Flat triangular ploughshare 200mm

Several ploughshare width in option

L blades right and left

ELEMENT X

For inter-rows from 60cm

To work up to 10cm depth

Suitable for hard stony soil condition

5 tines 45x12mm

Straight reversible ploughshare

Triangular shares optional – W element

Curved 32X12 tine with :

– Triangular duckfoot 70, 105,

150, 175, 200 or 250mm

– Reversible straight share

Rigid fitted 32x12mm tin adjustable with its 50 to 300mm wide triangular plough share

32×12 tine with adjustable rigid holder and right or left L blade

Large clearance 45x12mm tine with :

– Reversible straight share

– Triangular ploughshare 150, 175, 200 or 250mm

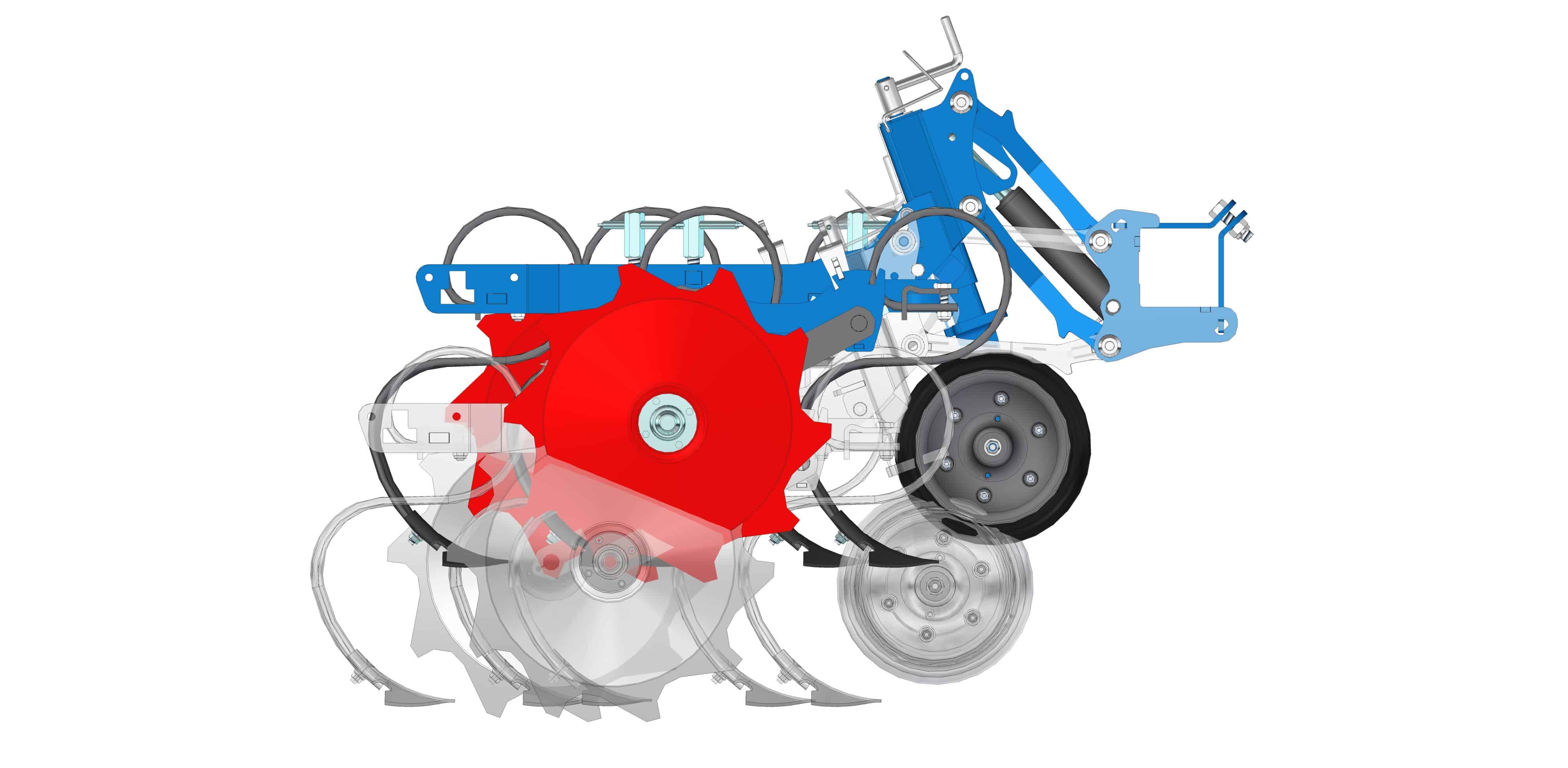

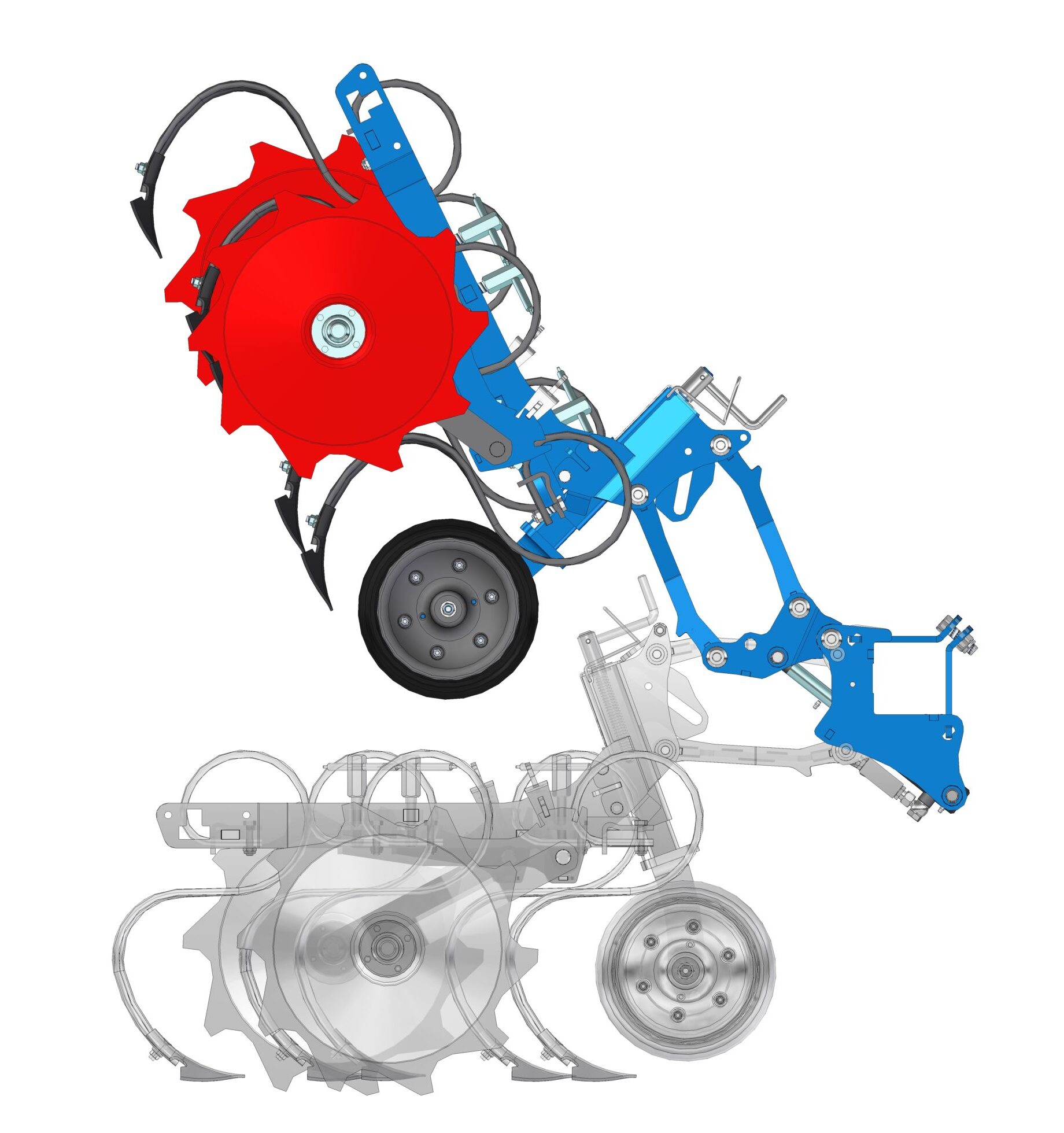

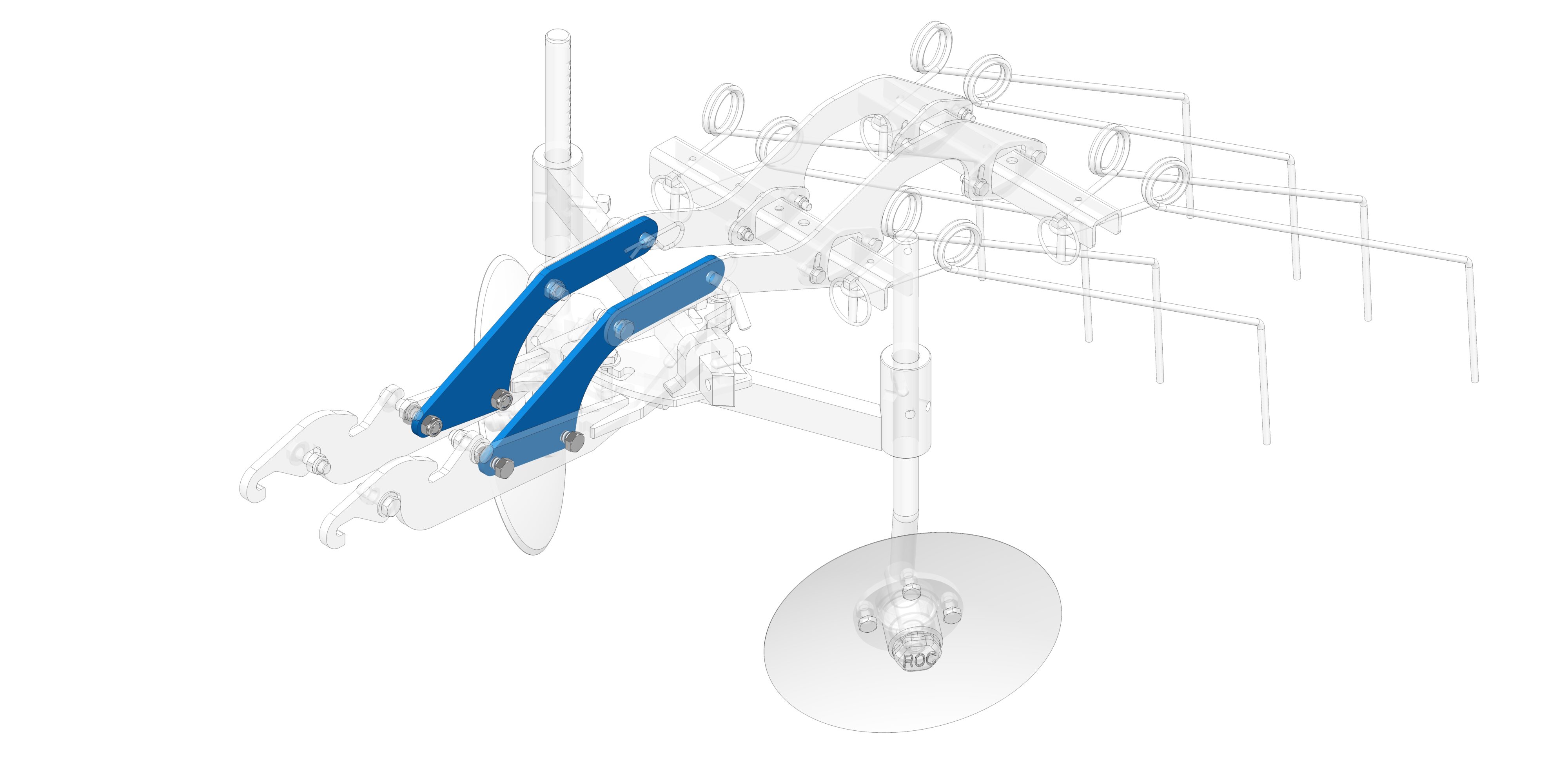

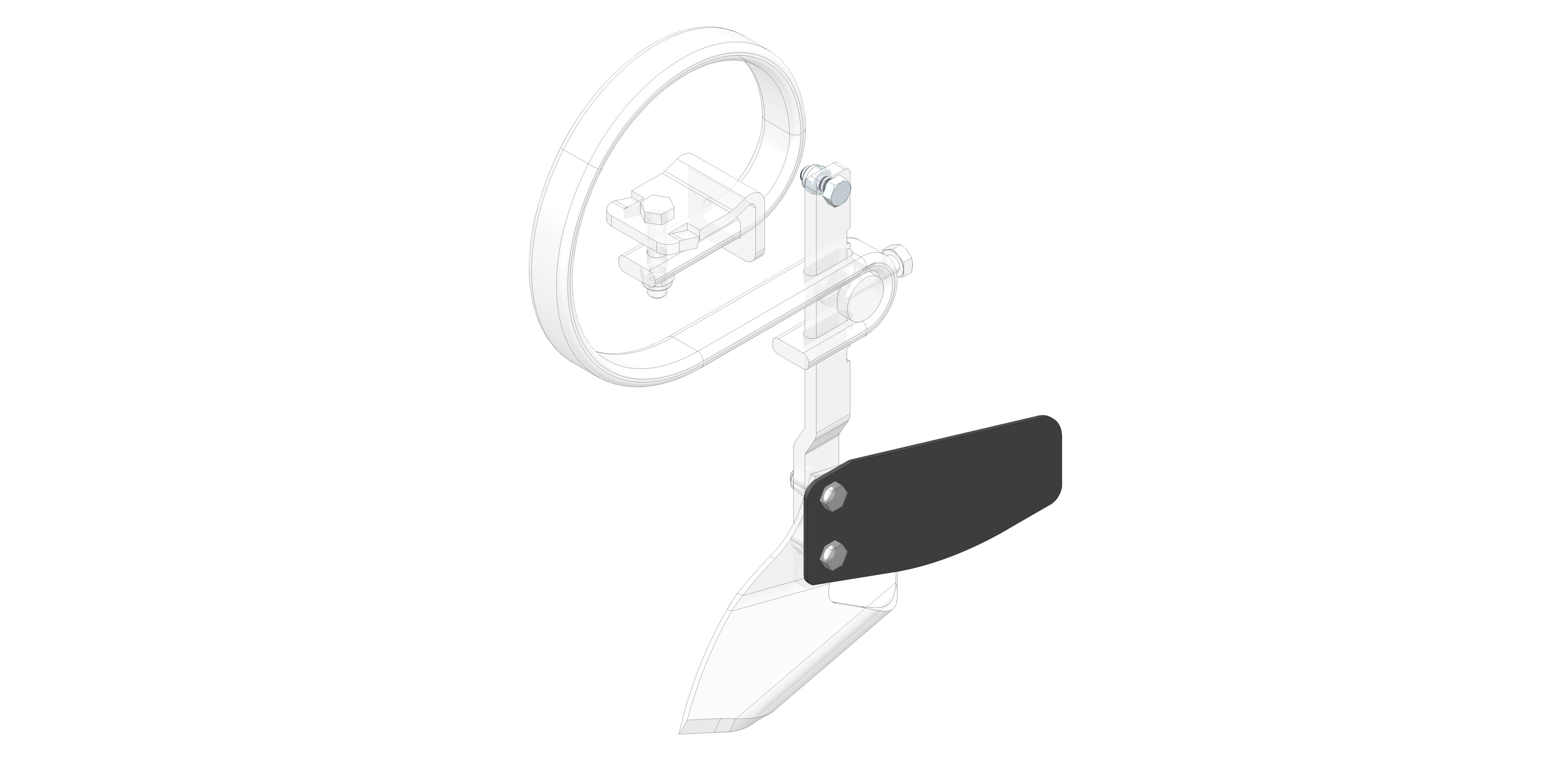

Retractable discs crop guard Ø500mm suitable for all conditions. Compatible with elements type E, L and X

Long retractable plant protector for optimal crop protection. Compatible with elements type E, L and X

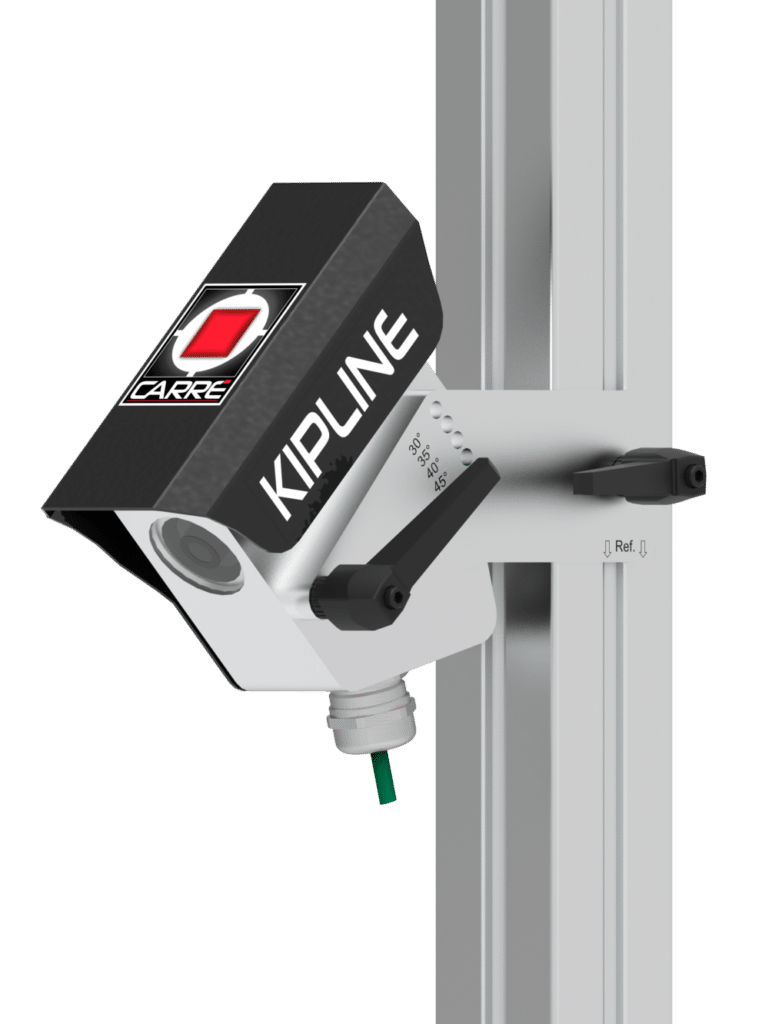

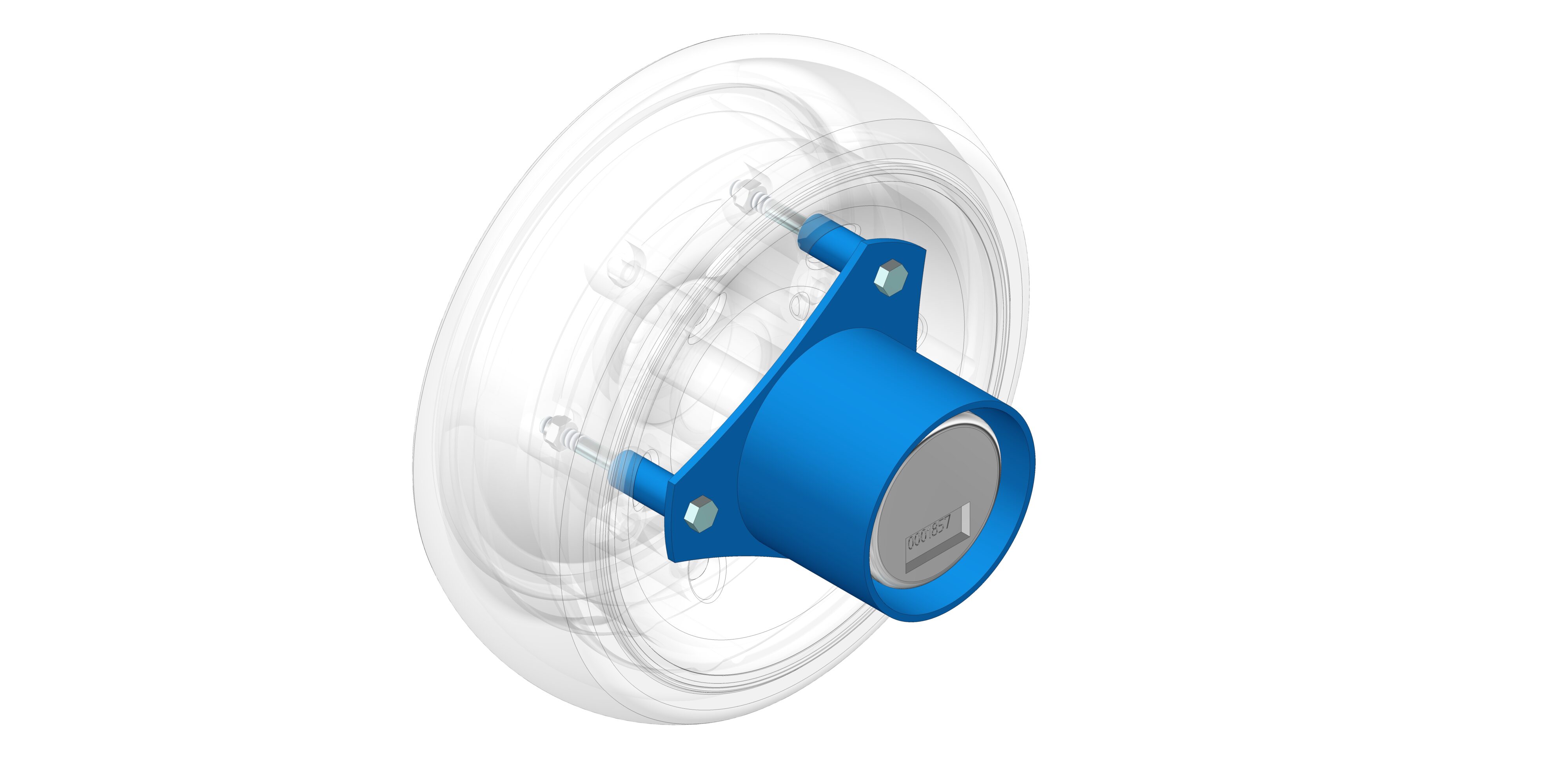

Easy and precise guidance

The KIPLINE camera guides the hoe precisely with

its high definition optical system which analyses

the entire colour spectrum.

Available with dual camera.

The ground-breaking efficiency of the image processing enables crop rows to be detected even in the presence of thick weeds, guaranteeing high-quality hoeing in all conditions.

Acts very early on, as soon as the plant reaches 3cm in diameter.

Manual control joystick included

Touch-screen monitor in the cabin for

real-time monitoring of the guidance

with an integrated screen connected to the camera. The ergonomic design and ease of use of the touch-sensitive console makes it very user-friendly.

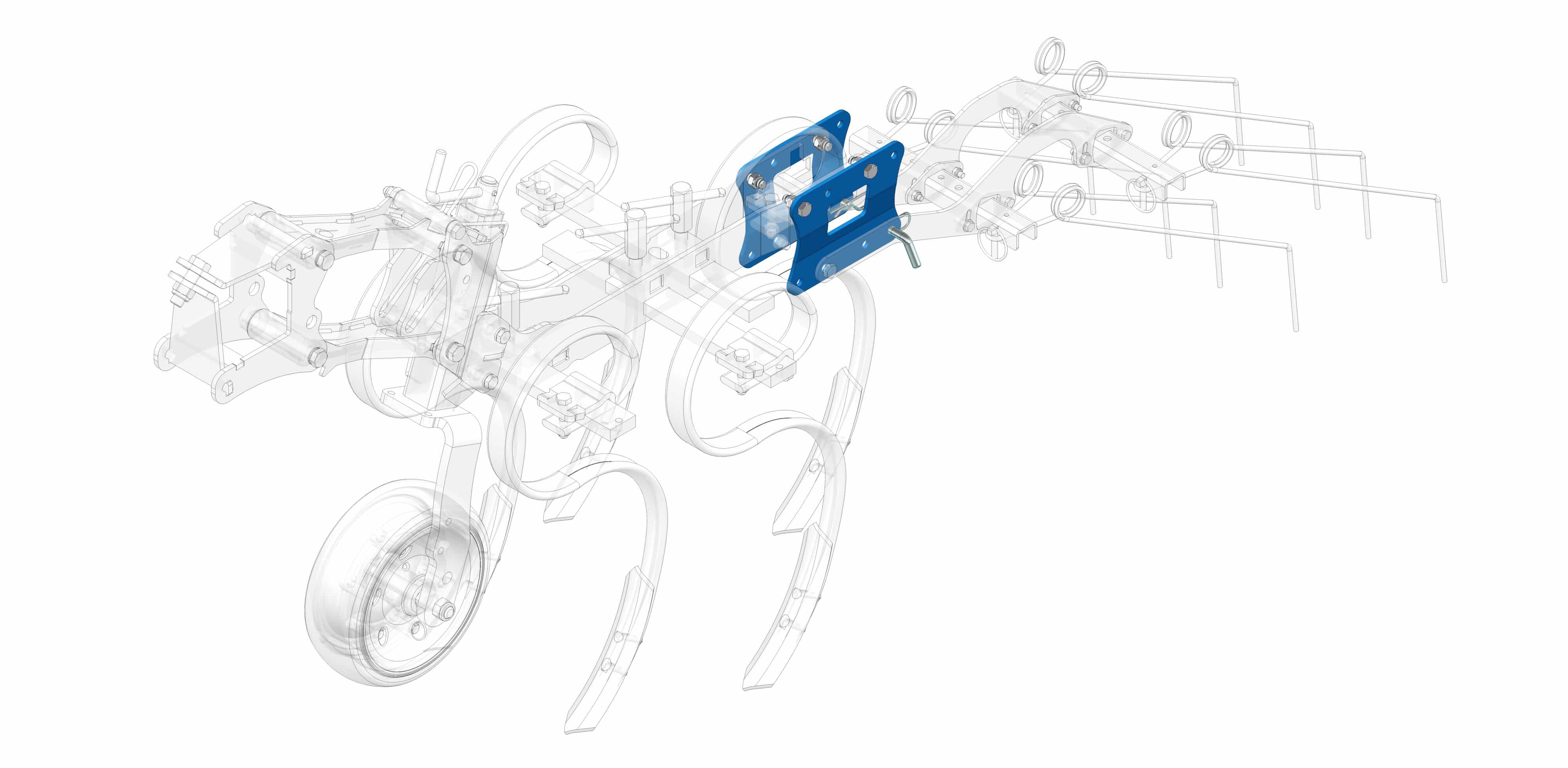

Guidance with sensors for crops with rigid stems such as maize or sunflower. Mounted directly on the interface or on the element to take information as close as possible to tines.

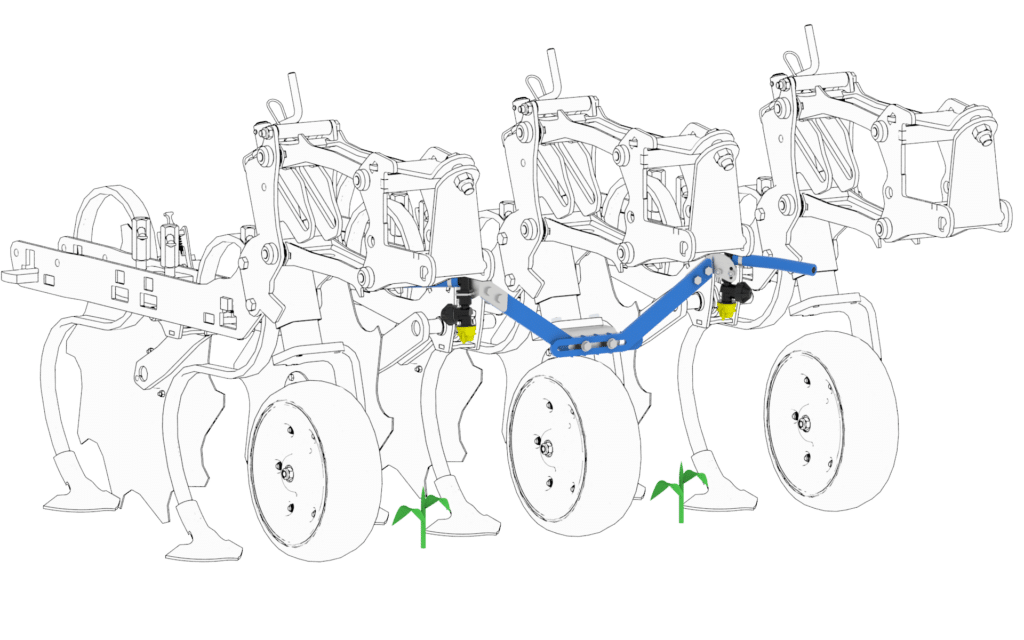

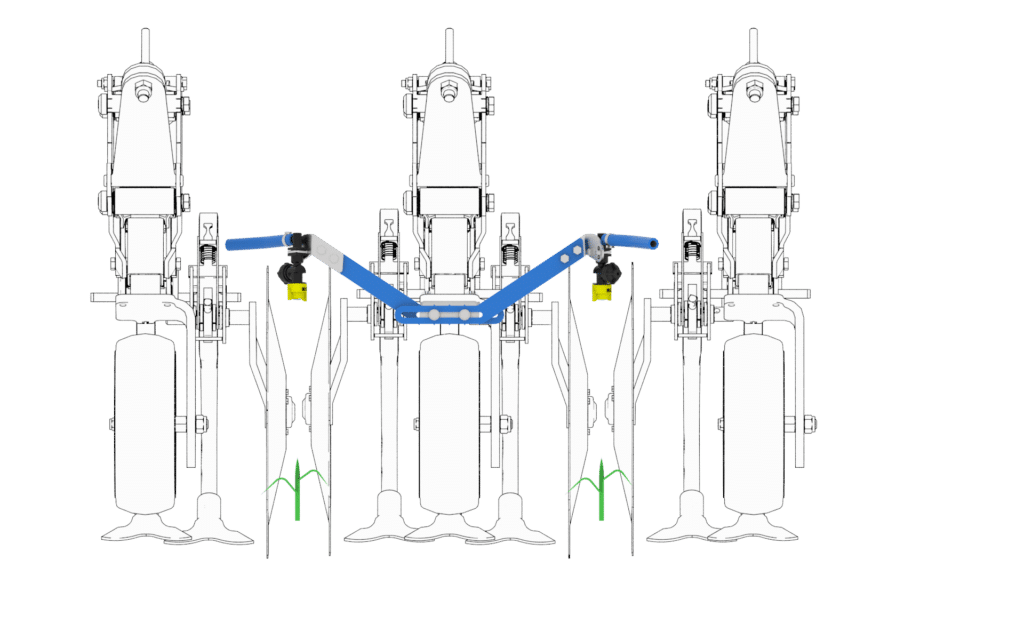

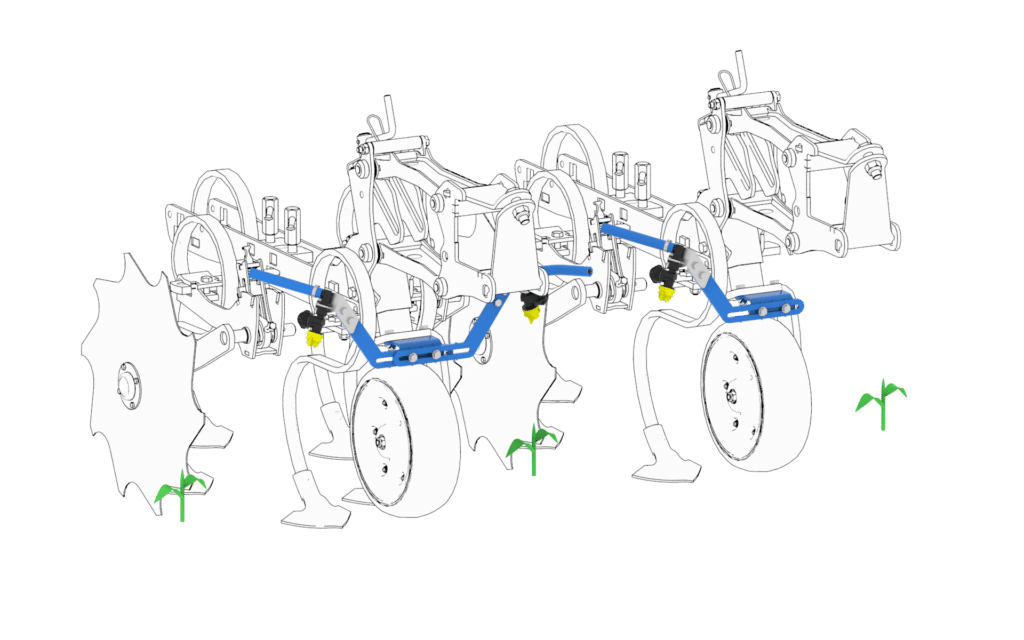

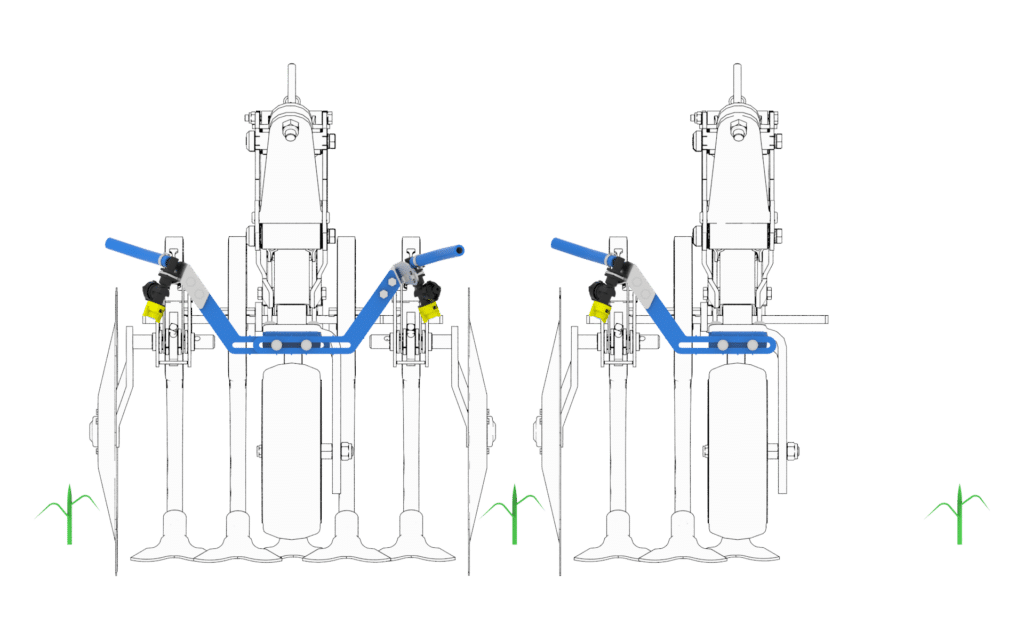

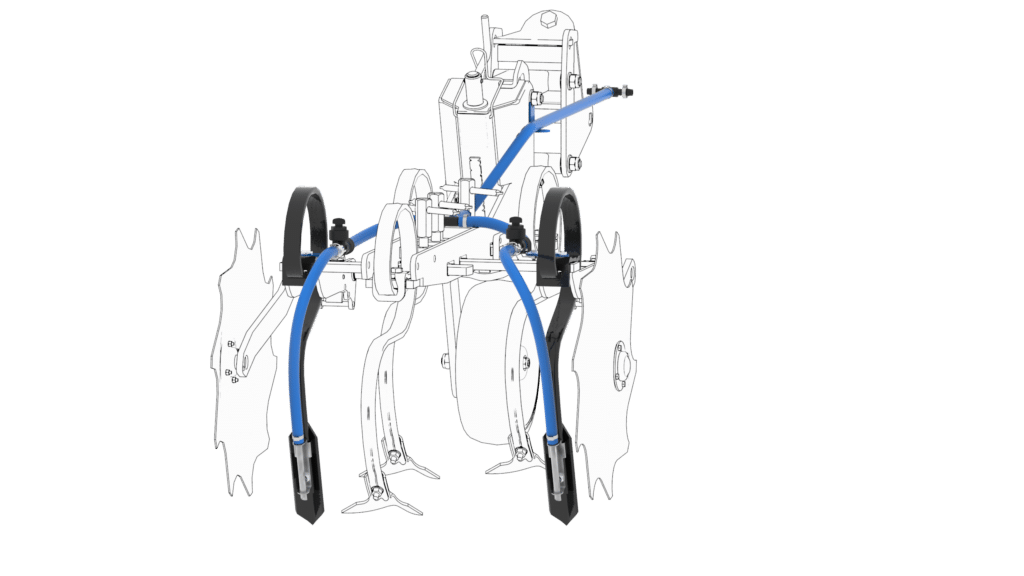

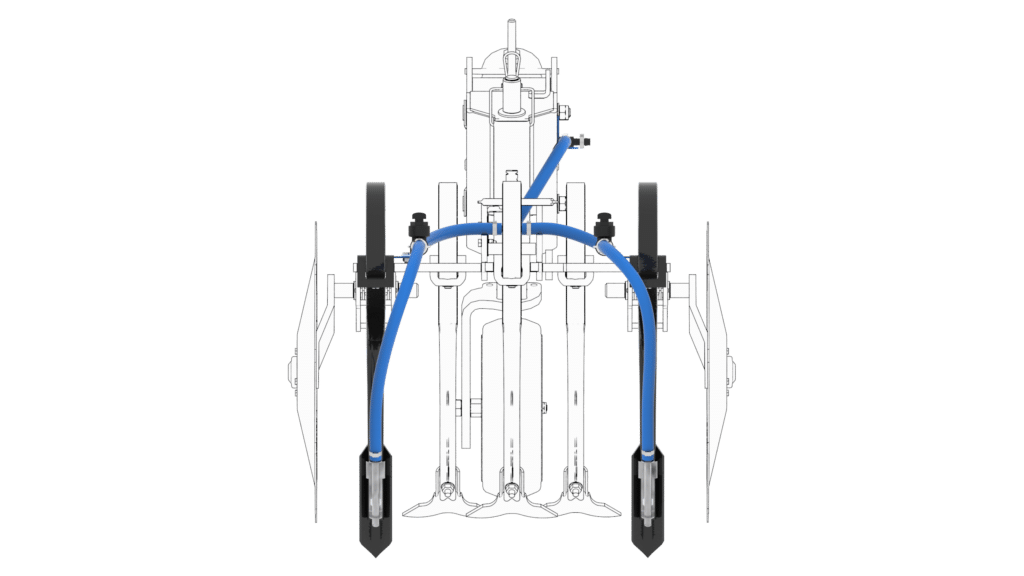

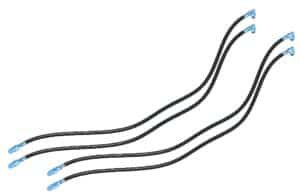

SPRAY KIT : Localised liquid fertilising and spraying!

Piping protection tamp over the entire machine.

Quick coupling on Ø18mm central output

Spraying over the 1 jet row

Stainless steel flat jet 40° with drip plate

Flow rate from 40 to 150 L/ha

Spraying on the 2-jet row

Stainless steel flat jet 40° with drip plate

Flow rate from 40 to 150 L/ha

Fertilisation with injector on either side of the row

St. steel strip till mounted on straight tines 38x12mm

St. steel disc Ø1 / 1.5mm with integrated anti-drip and shut-off valve

Flow rate from 80 to 400 L/ha

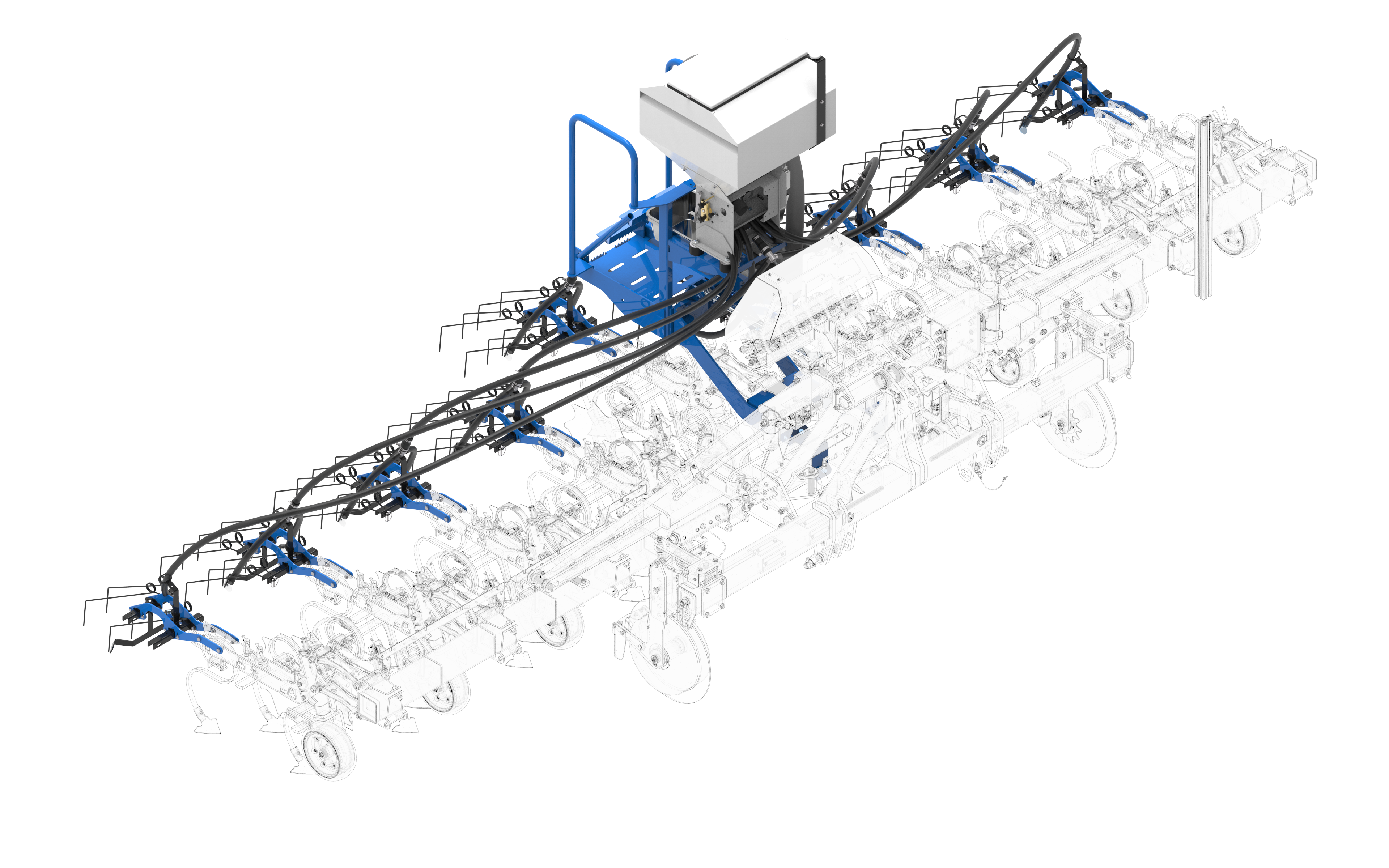

Sowing seed by surface broadcasting at the same time of hoeing

LIMIT SOIL EROSION AND TRAP NITRATE !

2 metering rollers for small and large seeds

8-flute distributor. For row spacing from 45 to 80 cm up to 12 rows

2 nozzles per row followed by 4 double combs

GPS-controlled control unit

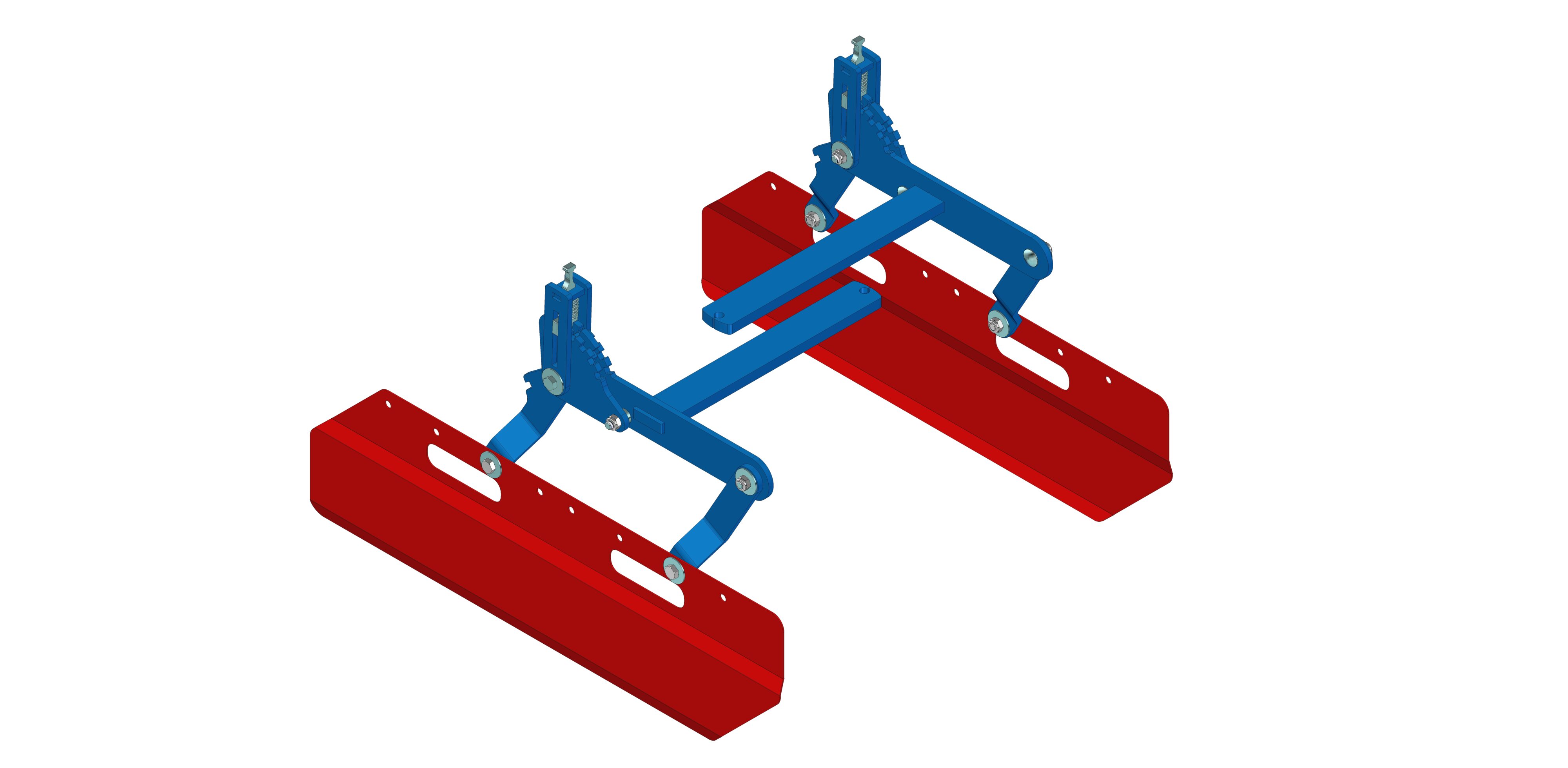

For FRONT HOPPER : solid fertilisation localizer

WEIGHT BALANCE AND ACCURATE DOSING !

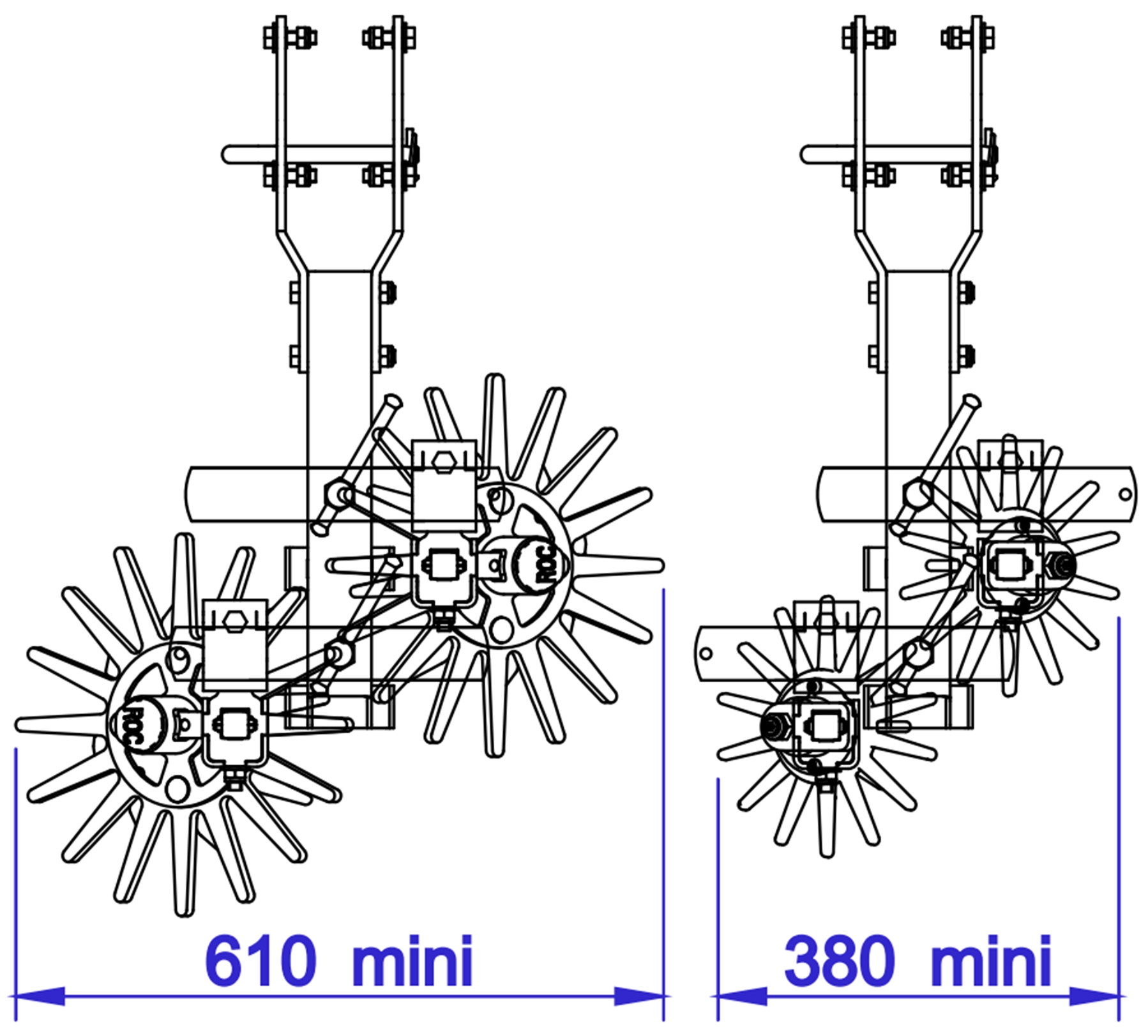

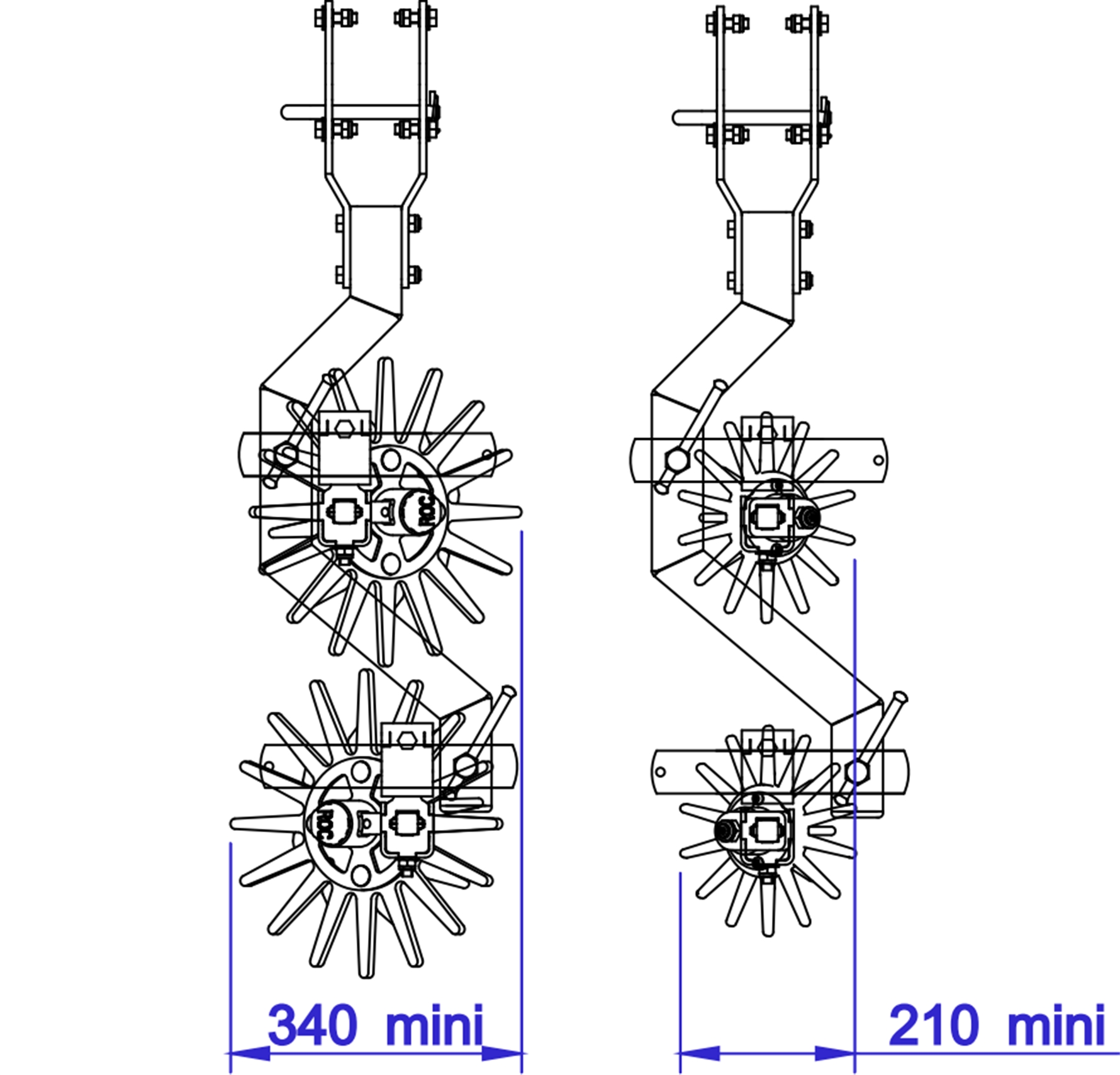

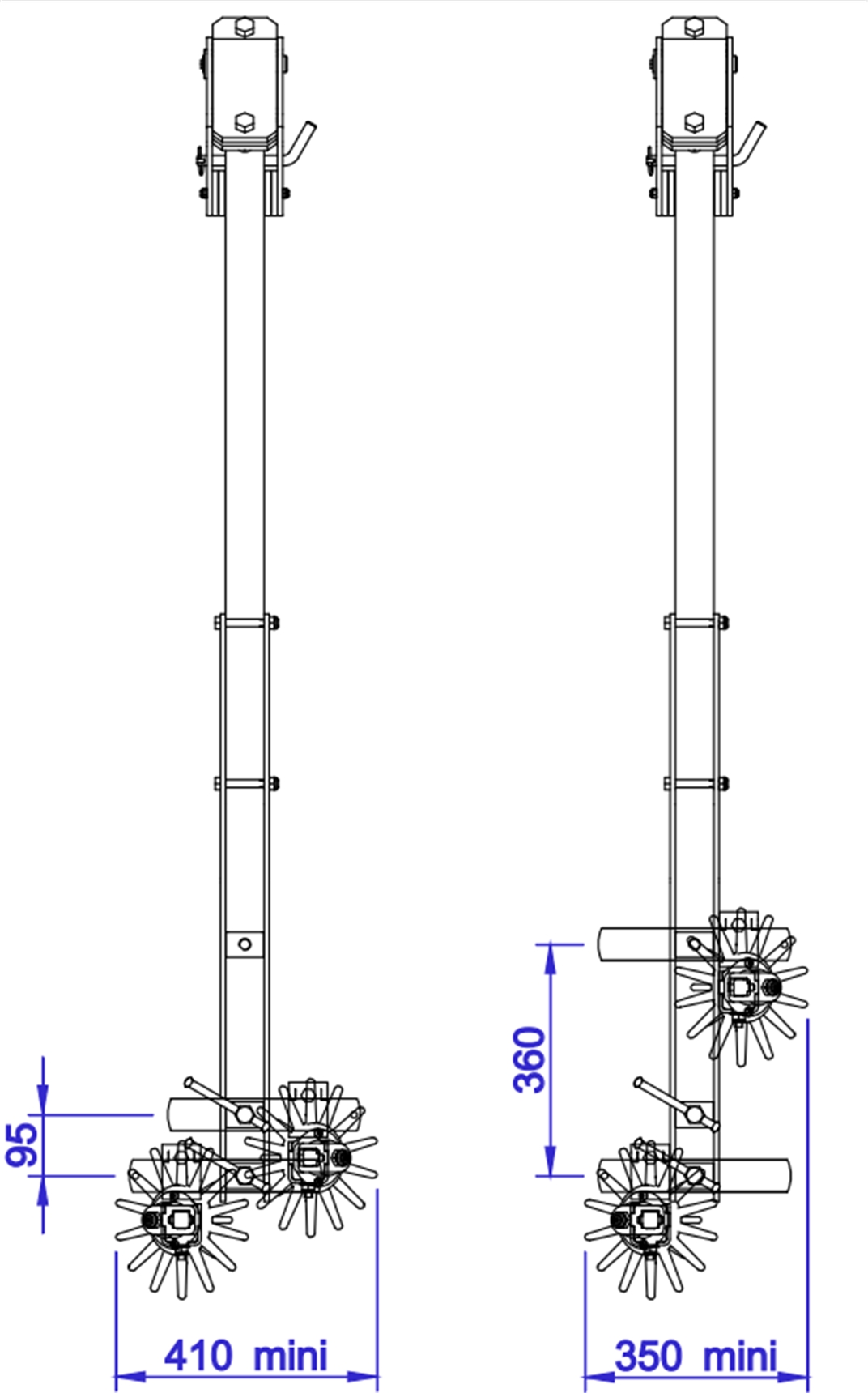

Netline can work in the rigid or floating position on soft soil and can be retracted when required Flexible star Ø360mm 16 tines, thickness 12mmor flexible star Ø240mm 14 tines, thickness 10mm

Fitted at the back of the element for inter-row from 0.45m to Compatible with ECONET F and ECONET with pushed linkage.

Not compatible with comb option

S fitting type

White star

or

Red star

Yellow star

Mounted at rear of unit for inter-row of 0m70 to 1m

Compatible with ECONET F and ECONET with push coupling.

Not compatible with comb option

Beam-type mounting

White star

or

Red star

Yellow star

Mounted on weeder beam for row spacing of 0.65 m to 1 m.

Compatible with ECONET depending on configuration.

Not compatible with rear comb option

Beam mounting

White star

or

Red star

Yellow star

Bracket for the fixing of the tracking’s

modul or seat

Seat to fix on the bracket

Independent hydraulic folding

of the extensions

Advanced 230mm hitch

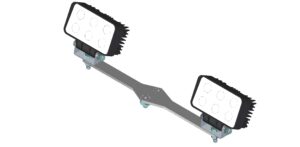

Dual camera

LED lights

Ridging ploughshare 350mm

L, B or X

Ridging ploughshare 600mm

with adjustable wings

L, B or X

Discs Ø300mm

L, B or X

Discs Ø510mm

L, B or X

Comb harrow in the inter-row

Comb harrow on the row

Adaptation for combination

of discs Ø300mm and comb harrow

Comb lowering kit if XL element

Surface measurement kit on wheel

Deflector for L blade

I and B

Opening discs Ø300mm

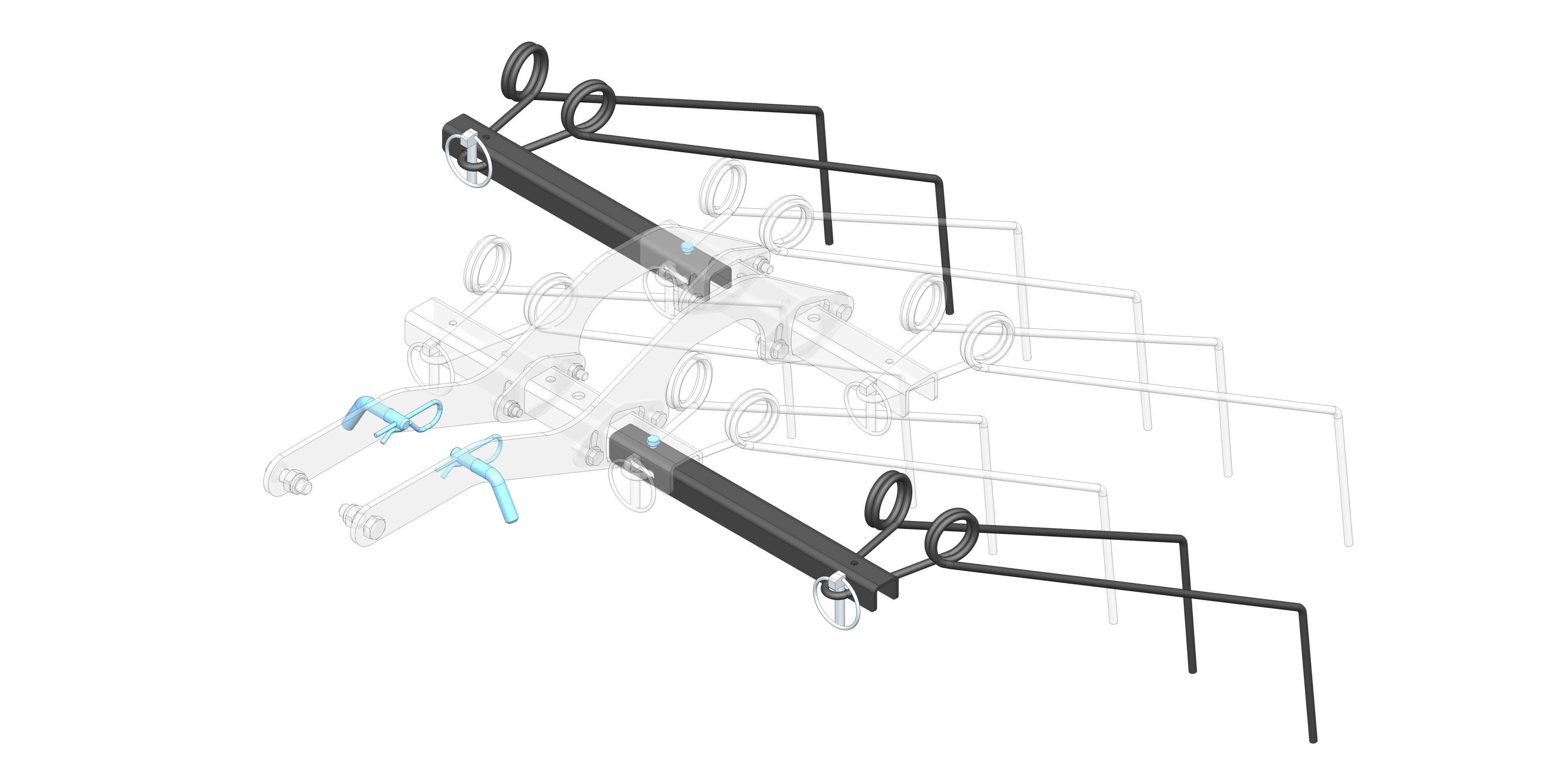

Pressure spring kit

Hydraulic lifting of horizontal hoe

elements

Hydraulic lifting of vertical hoe

elements

Control wheels 10PR Ø550 x 175mm

Lateral offset interface