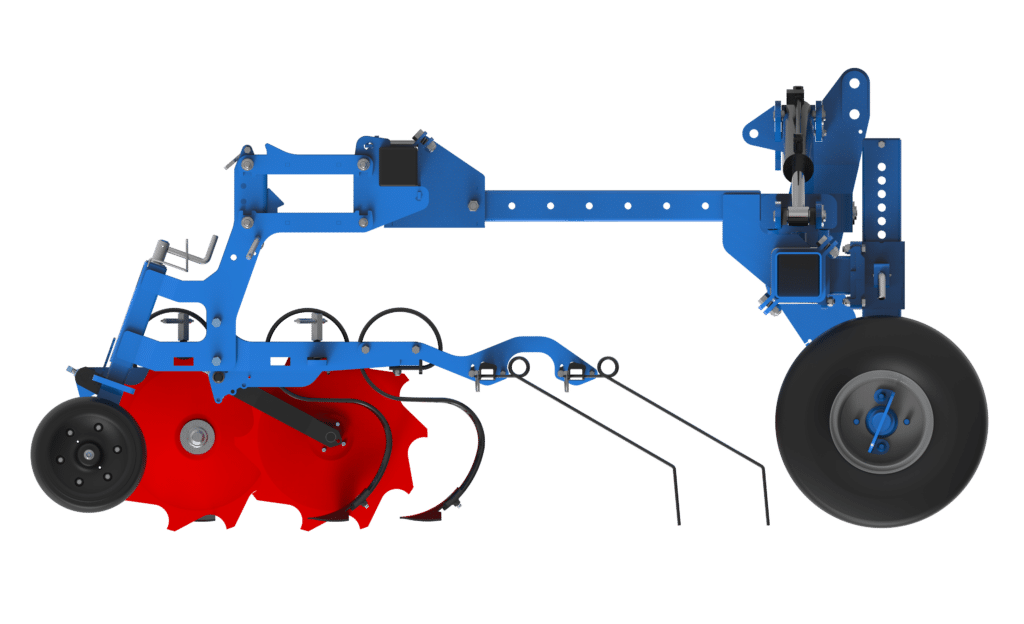

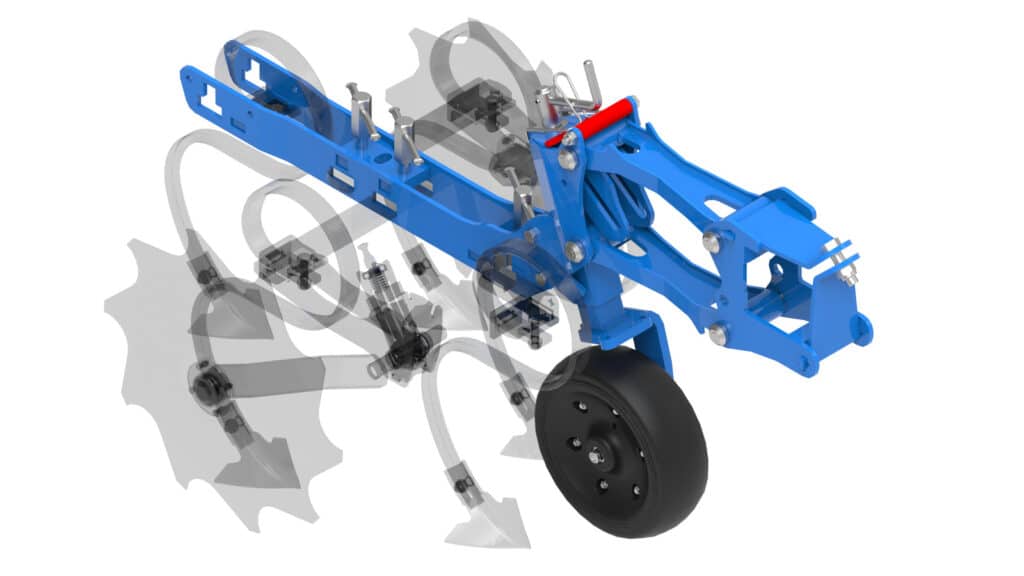

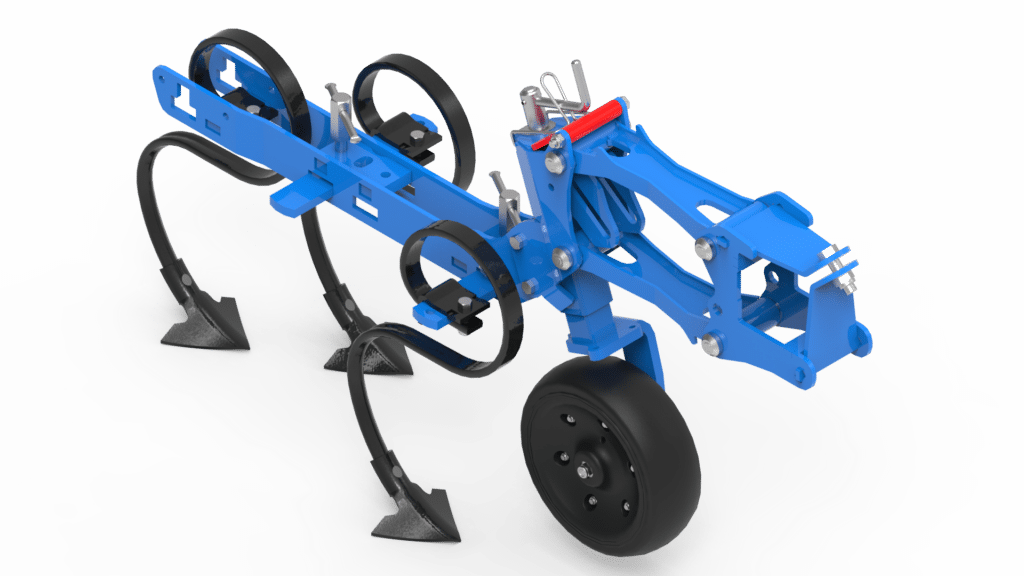

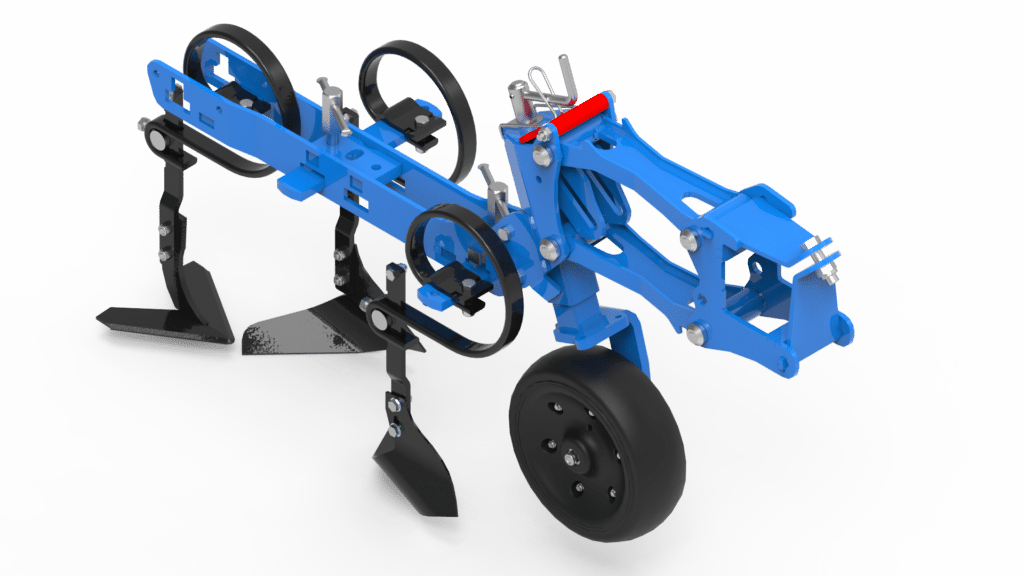

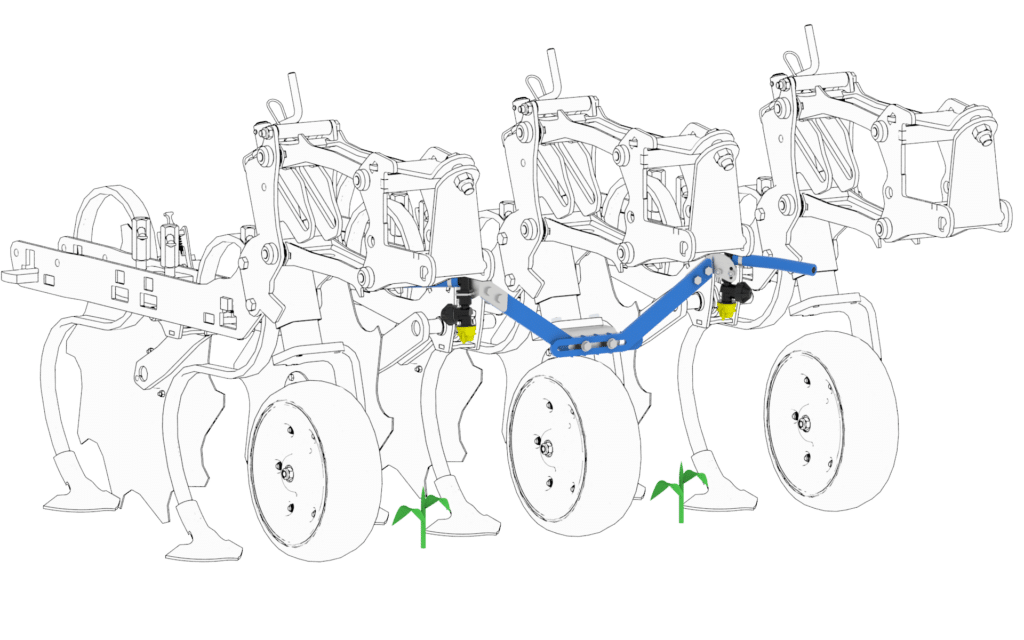

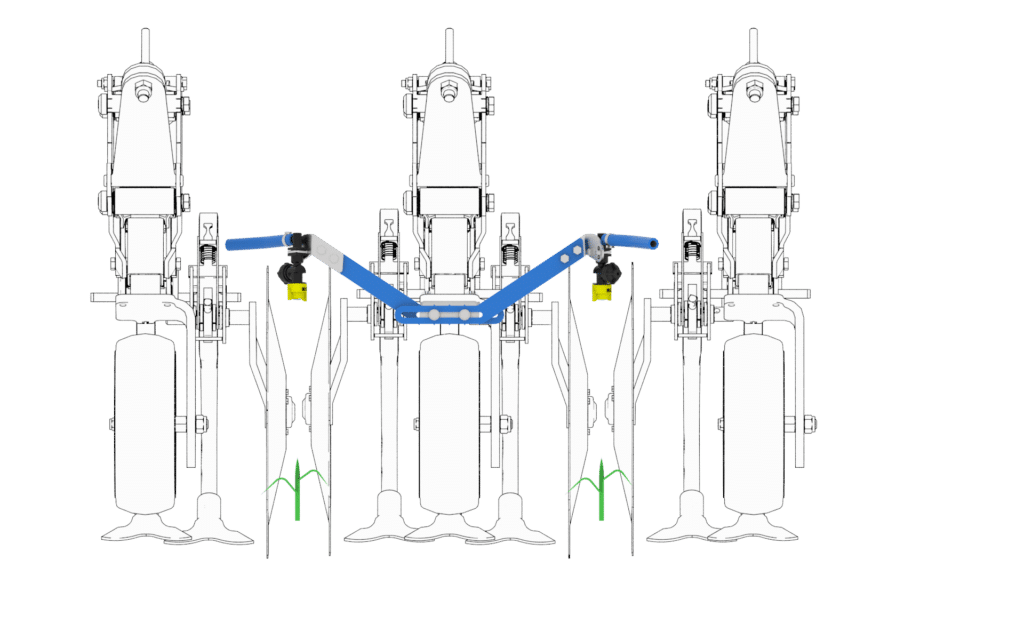

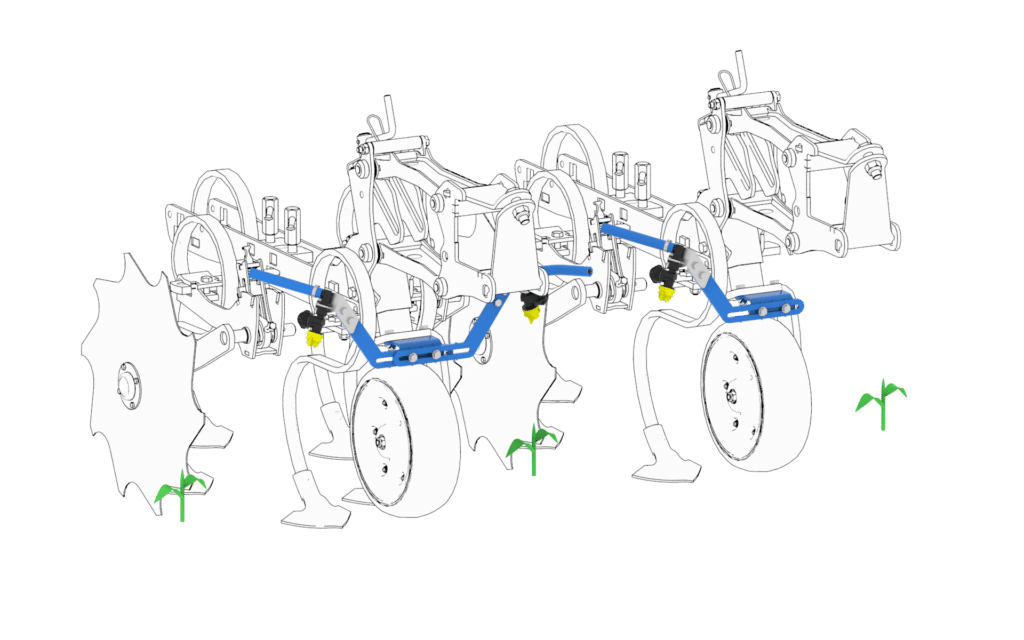

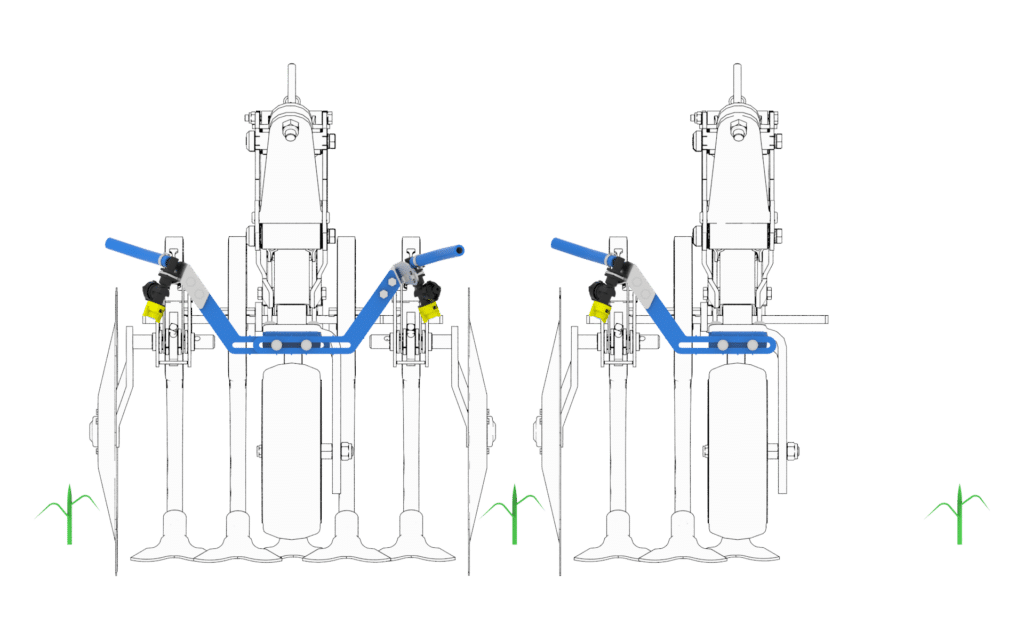

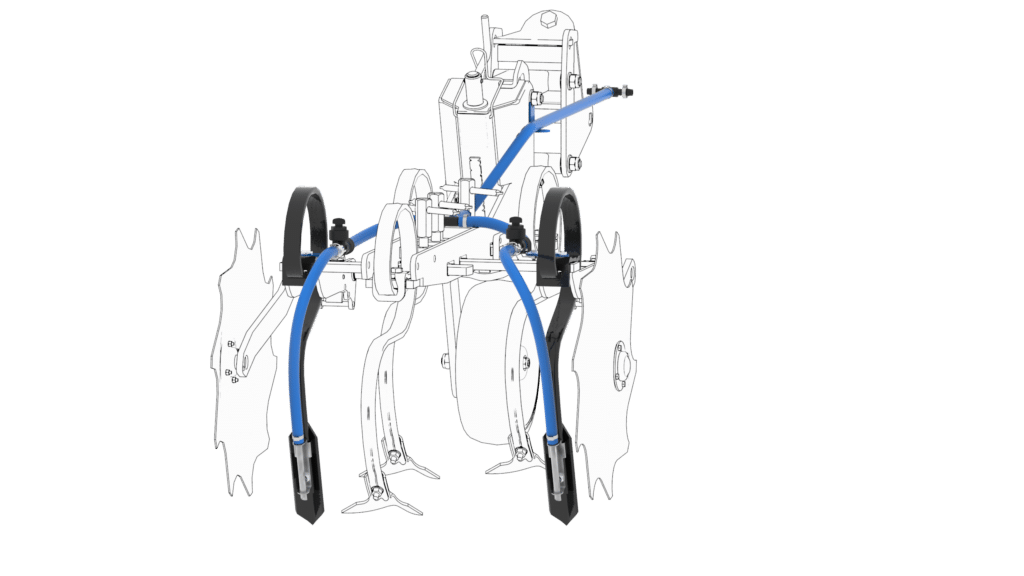

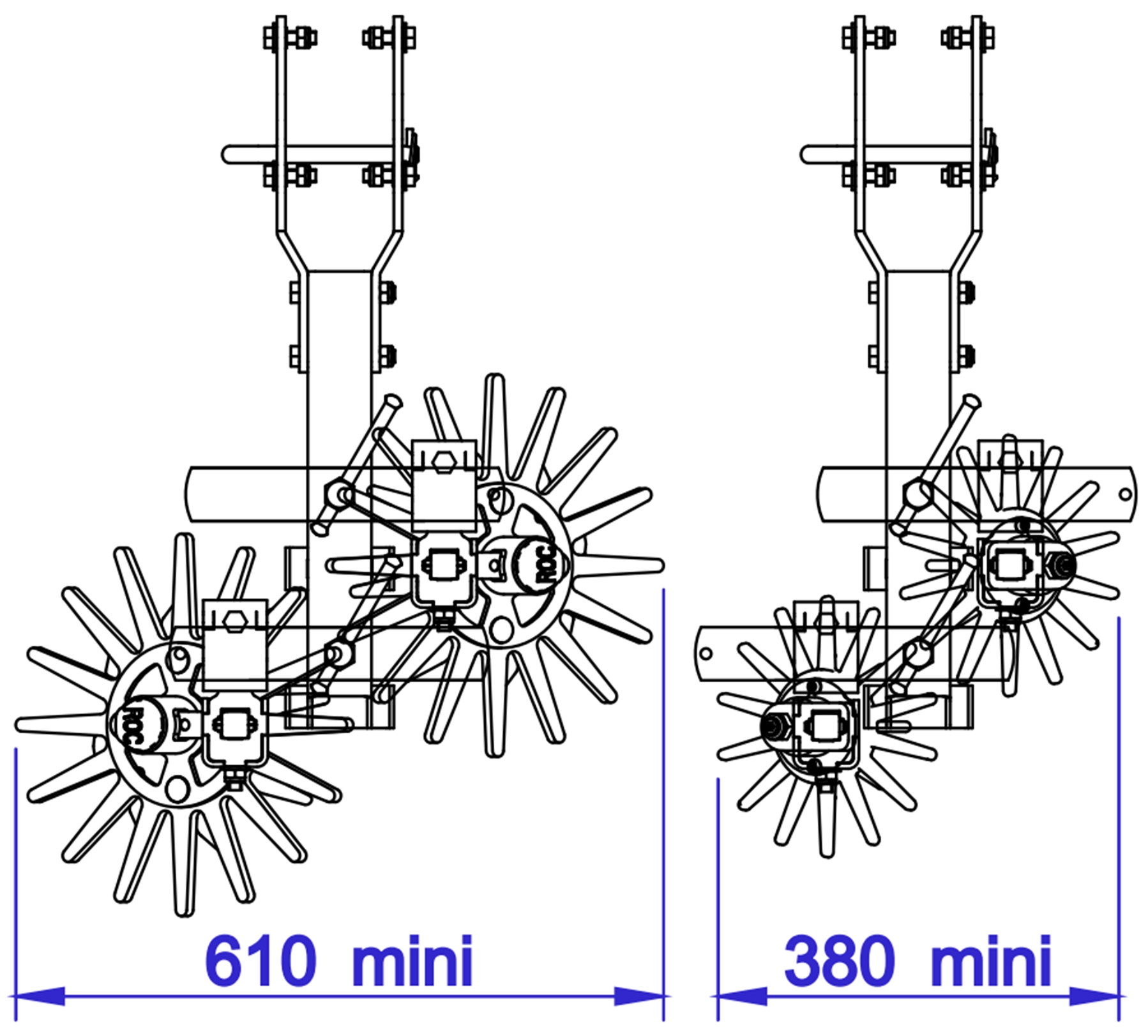

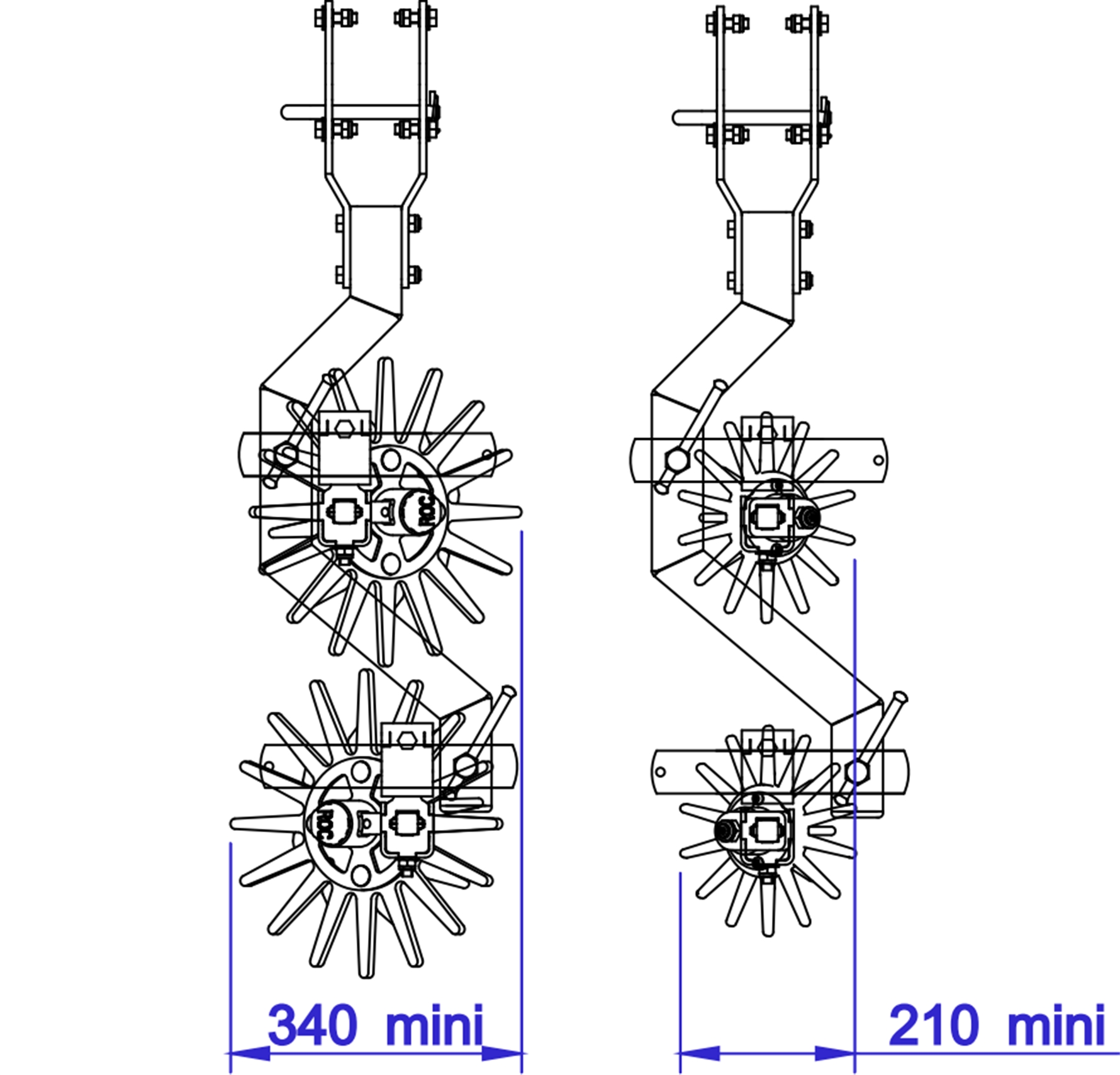

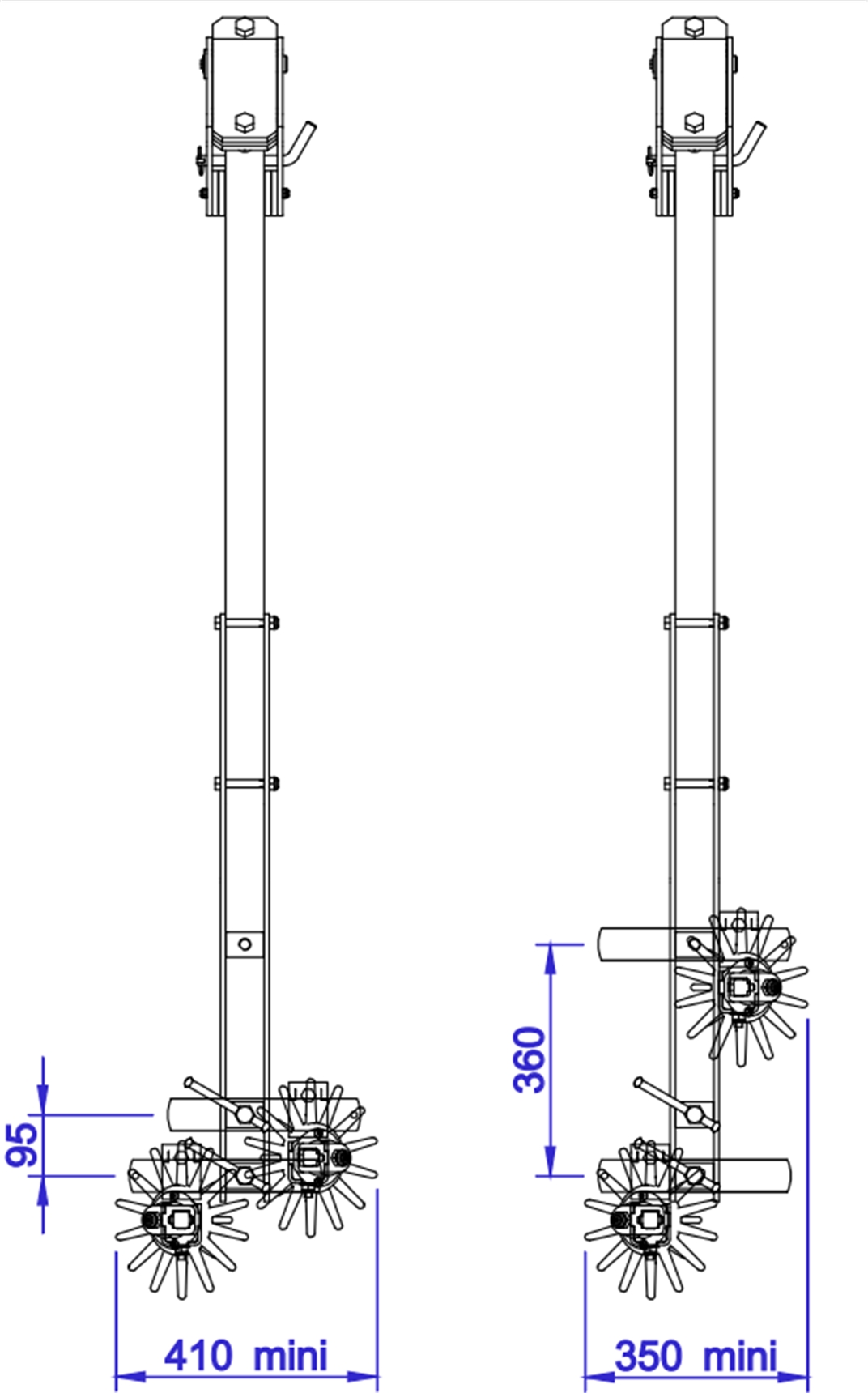

Because some prefer hoeing at the front of the tractor, we have designed a specific range to meet this need.

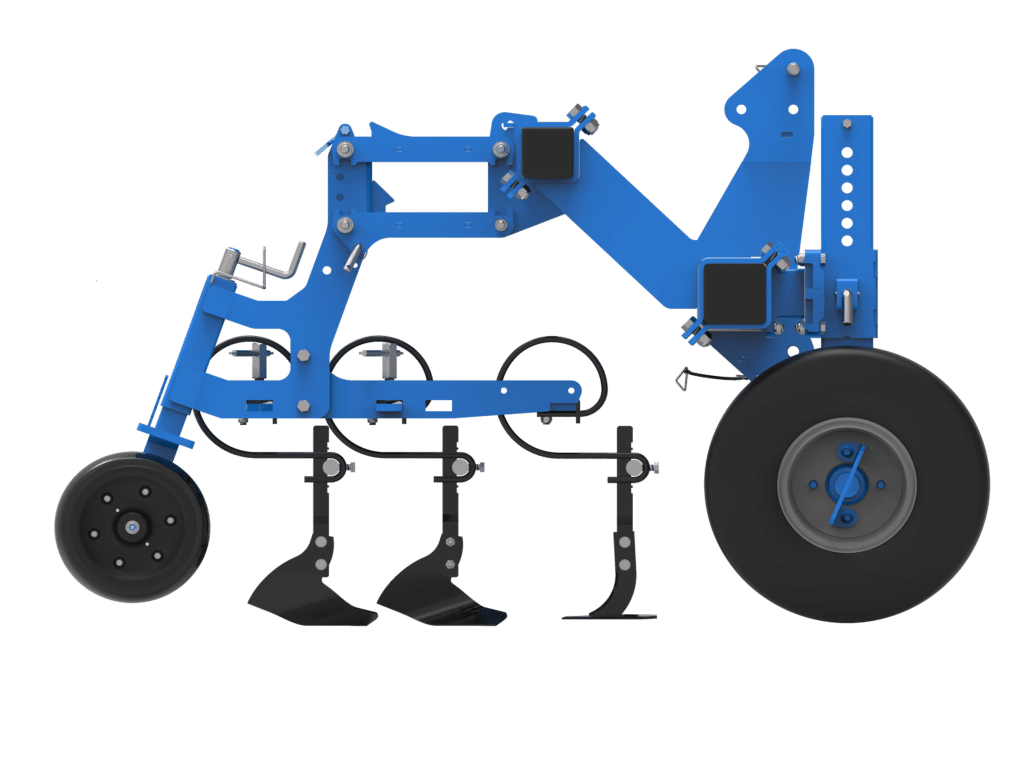

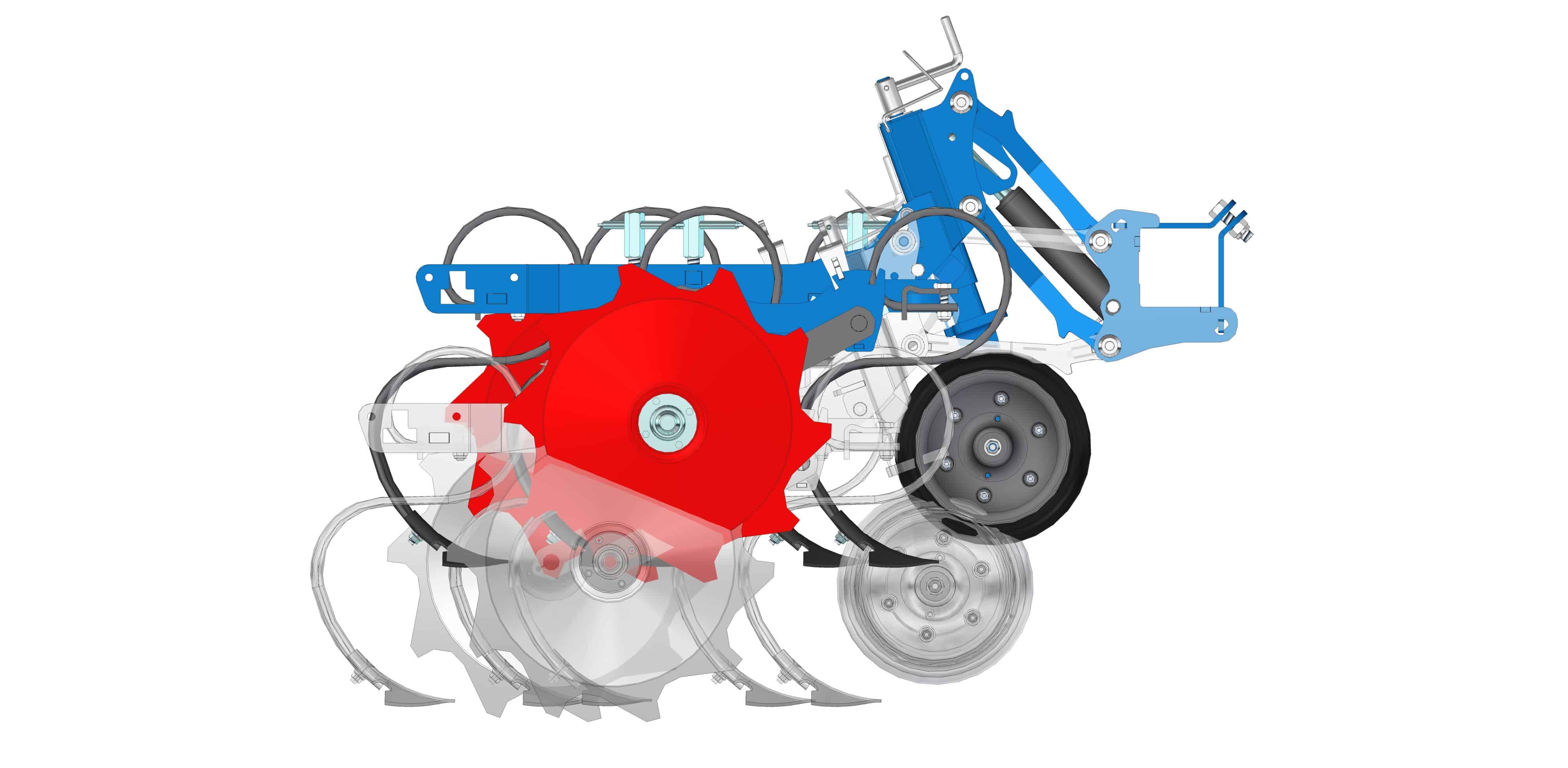

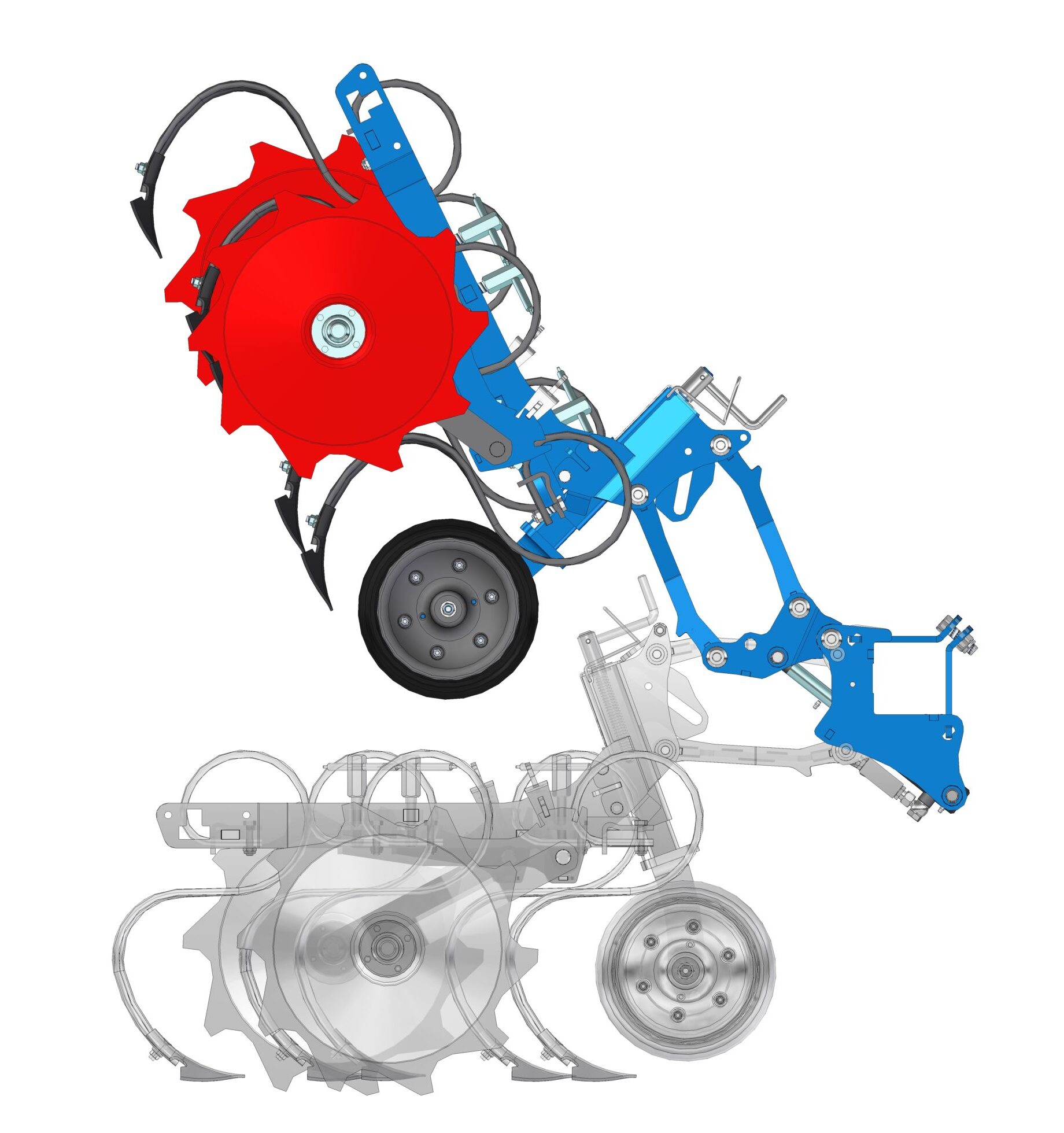

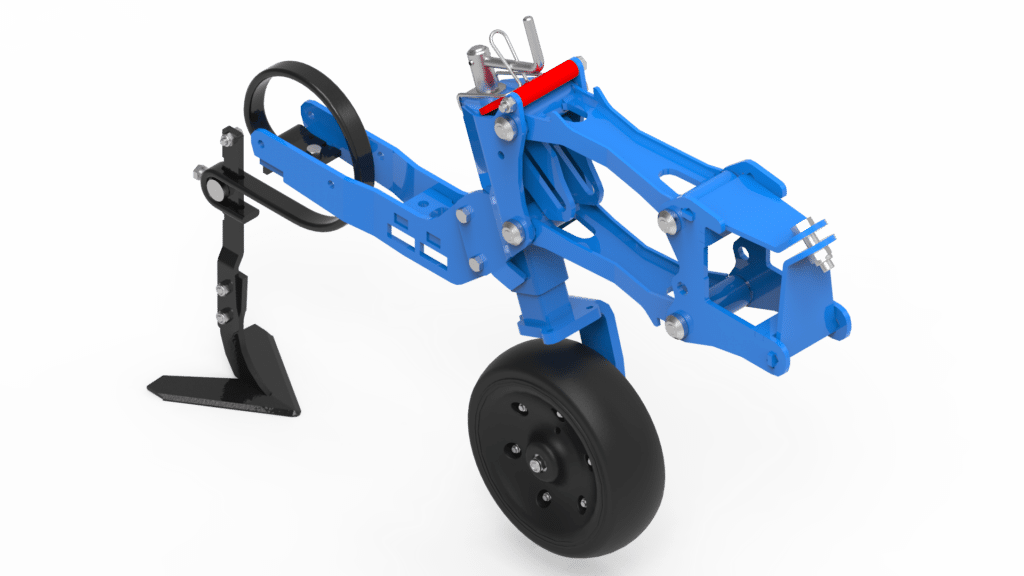

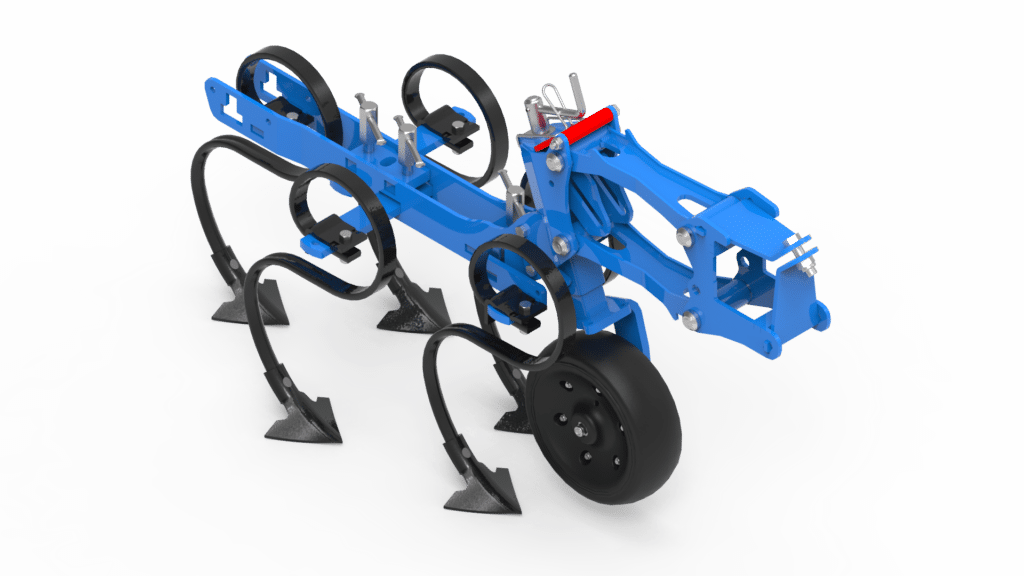

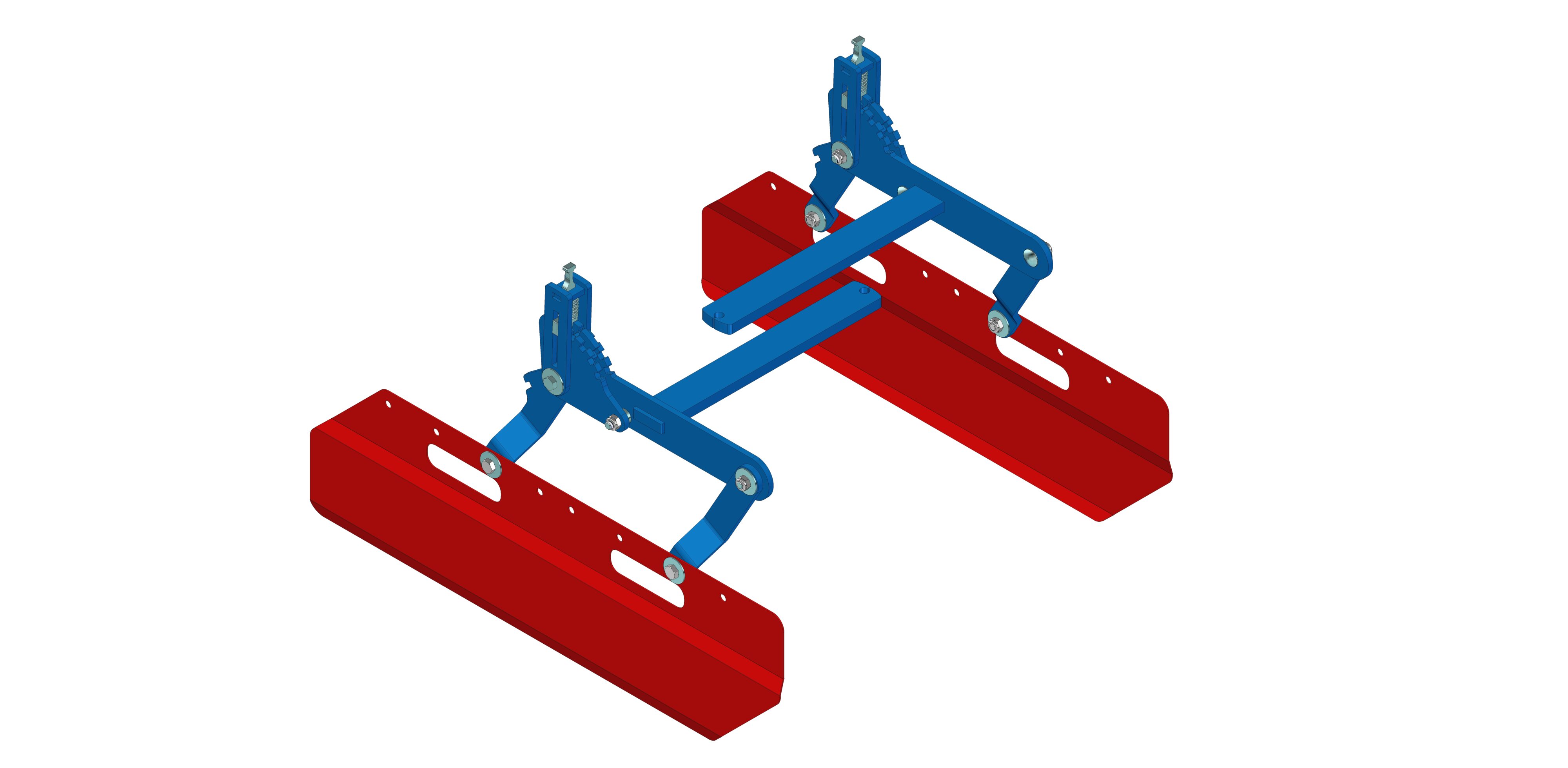

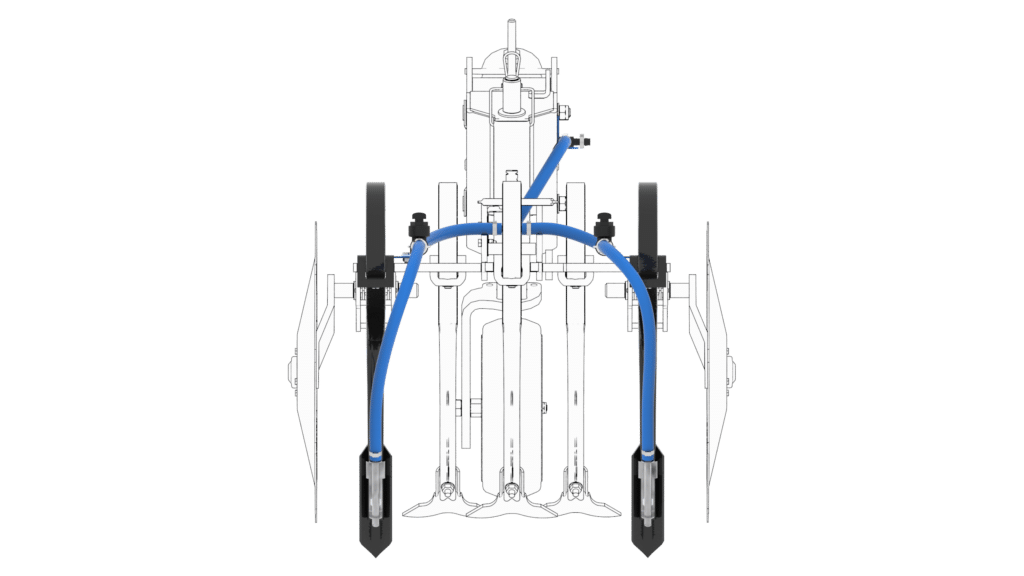

The element has been designed to be front-mounted and our beams can be fitted with equipment behind the element.

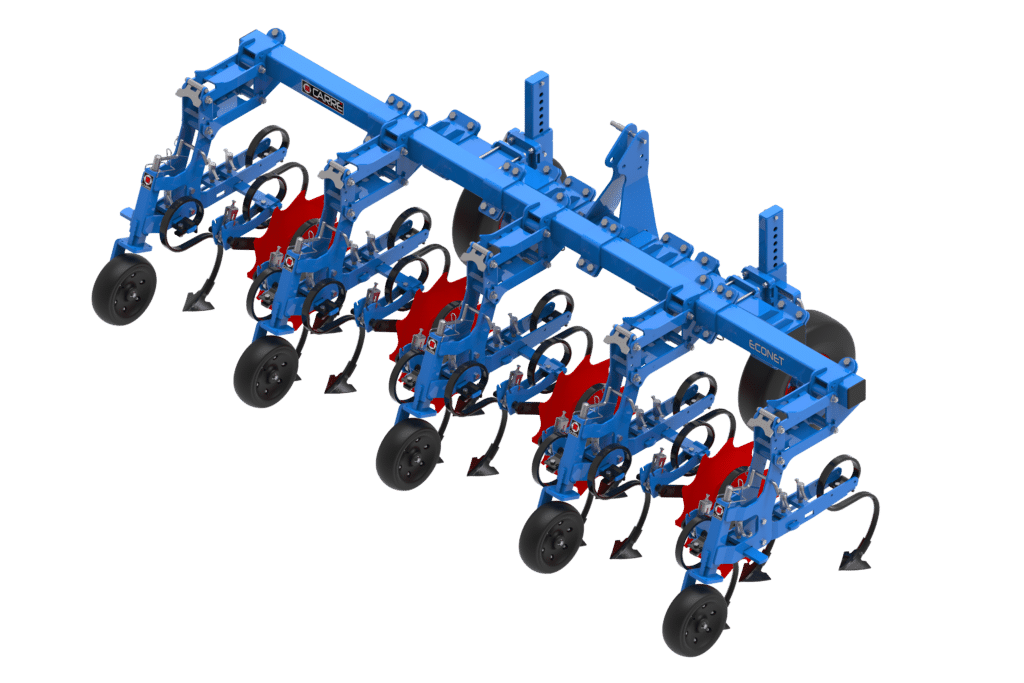

Available from 6 to 12 rows !