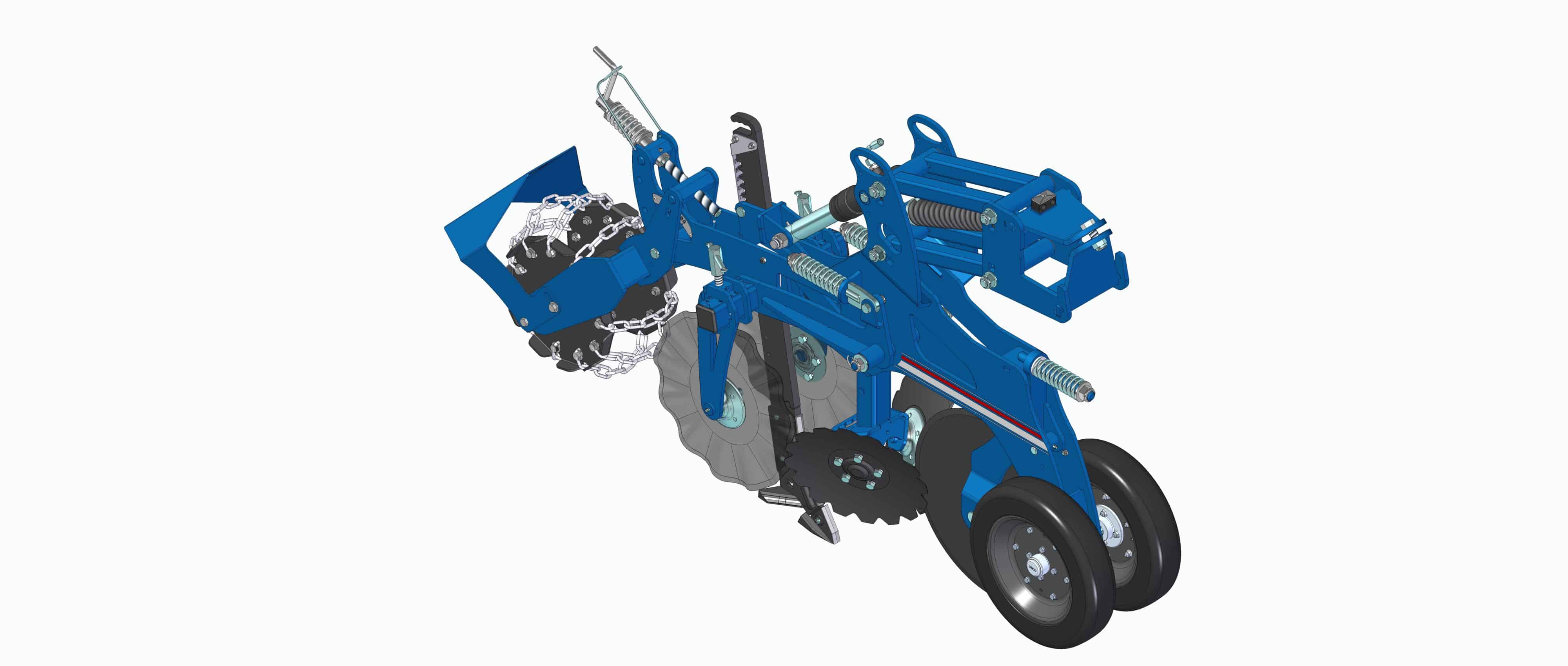

CARRÉ offers different frames according to the number of elements to obtain the best cost / resistance / versatility ratio :

- Single beam chassis are ideal for crops with fixed-interval and a small variety of conditions,

- Twin-beam chassis meet the needs of those who wish to use a machine on a wide variety of crops with different inter-row spacings.

- Triple beam chassis are design for big width mounted versions and maintain extensions in sandwich for high rigidity.

Using our experience in hoeing, we have designed an element optimized for row work only.

Each element is mounted on a paralellogram and benefits from its own pair of depth wheels to ensure a regularity in the working depth from one end to the other of the machine whatever the width of the tool.

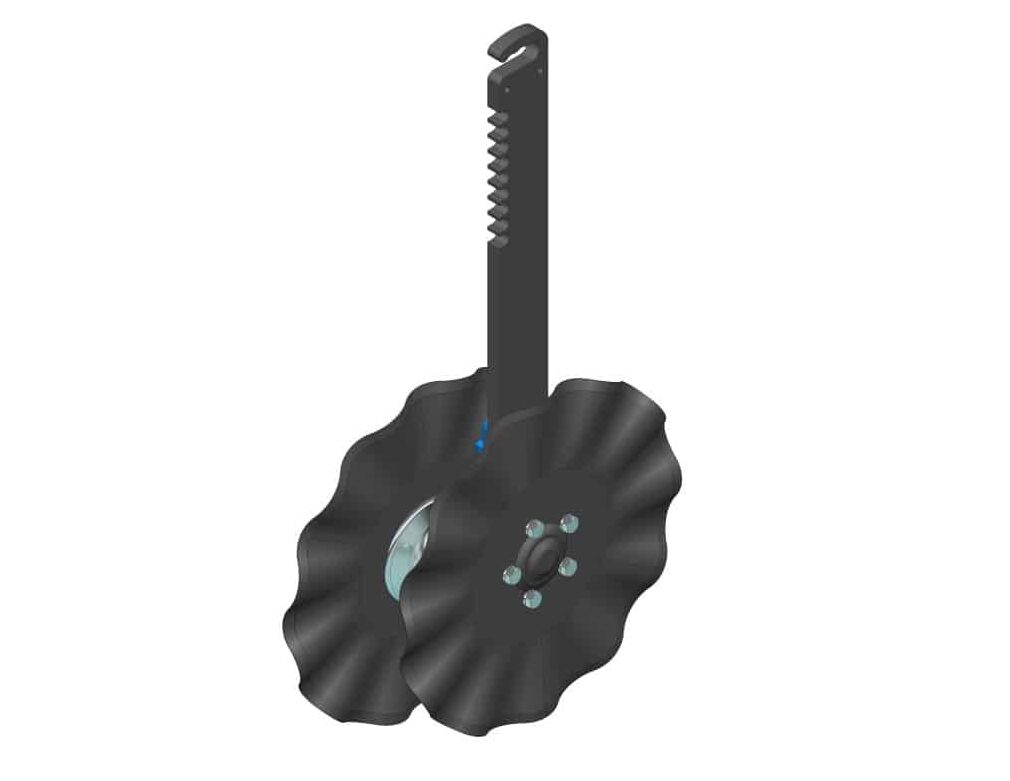

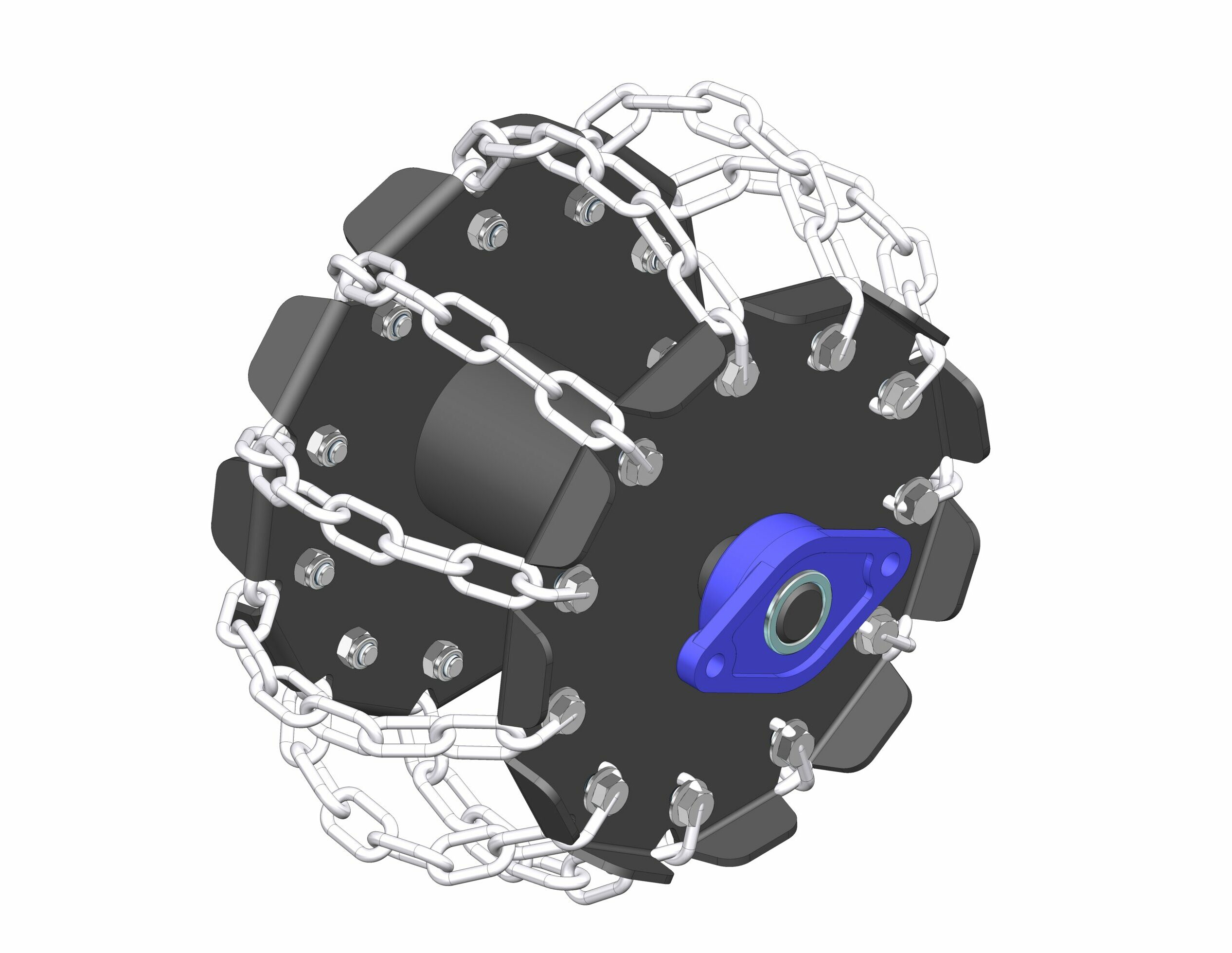

Each disc is mounted with its own security and can be independently adjusted. Numerous adjustments are possible, all by hand and without tools (trash wheel discs, deflector discs, working depth and re-pressing of the roller). Visual elements make it possible to quickly check all the settings of the machine and to reproduce them on all the elements.

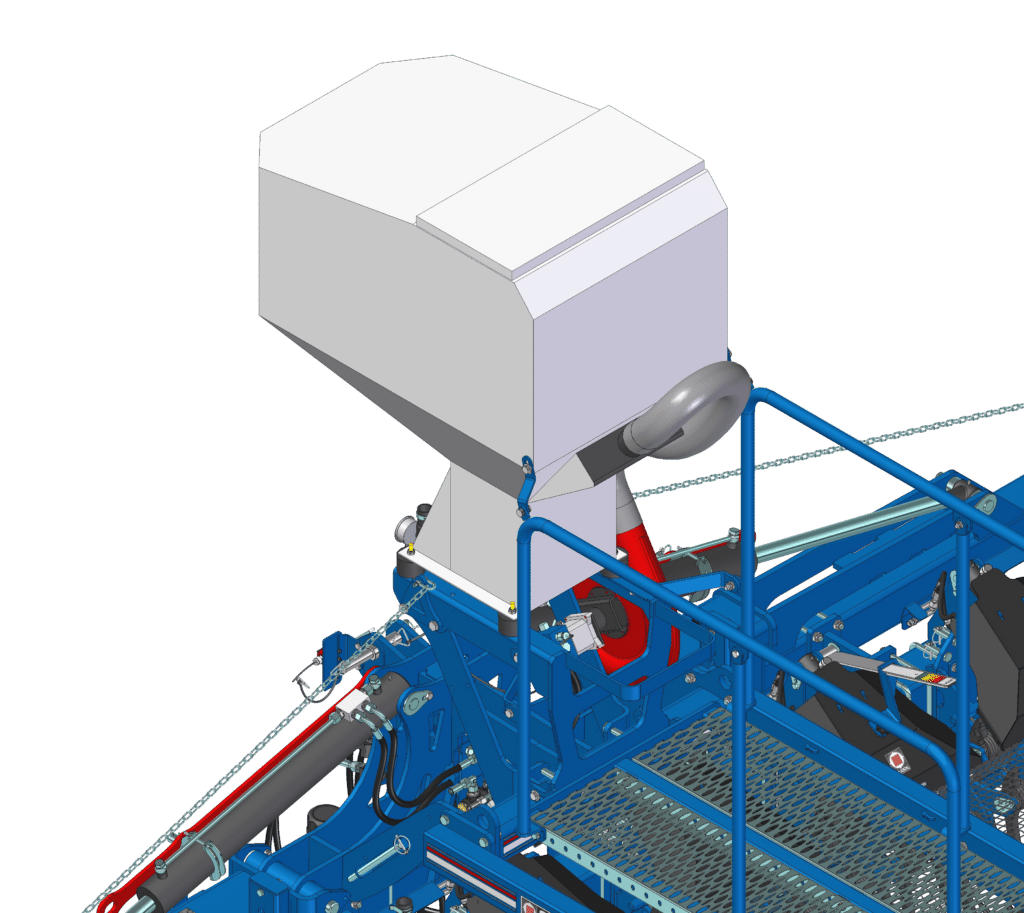

Hydraulic non-stop version for more comfort at work Double hydrau-mechanical safety locking (transport and work)

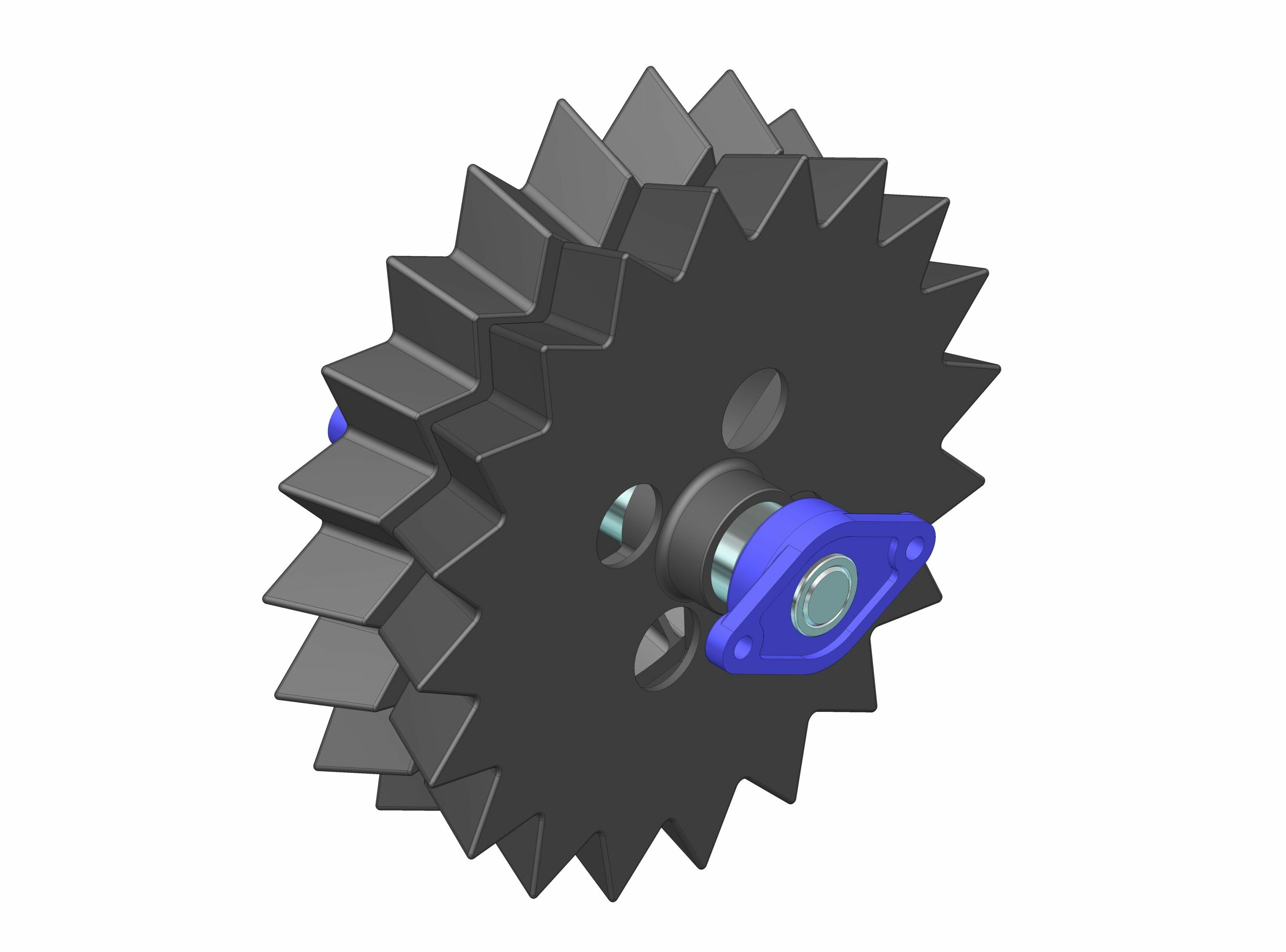

Hydraulic non-stop version for more comfort at work Double hydrau-mechanical safety locking (transport and work)  The tine can work between 5 to 30cm depth. Points, legs, and wings are in carbid as standard 2 types of elements to be chosen depending on inter-row spacing

The tine can work between 5 to 30cm depth. Points, legs, and wings are in carbid as standard 2 types of elements to be chosen depending on inter-row spacing